How to change the bearing on a Samsung washing machine

Samsung washing machine of any model is of good quality and long life. No matter how good the car is, the time comes when it begins to demand attention. In particular, a bearing often breaks in such a machine. It would seem a “trifling matter”, it’s worth a penny and replacing is as easy as shelling pears. But it wasn’t there, you still need to get to this bearing correctly, and then remove it correctly without damaging anything. This is already a task!

Samsung washing machine of any model is of good quality and long life. No matter how good the car is, the time comes when it begins to demand attention. In particular, a bearing often breaks in such a machine. It would seem a “trifling matter”, it’s worth a penny and replacing is as easy as shelling pears. But it wasn’t there, you still need to get to this bearing correctly, and then remove it correctly without damaging anything. This is already a task!

What do we need for repair?

The bearings in the Samsung washing machine are not being repaired, but are being changed, therefore, first of all, we should take care of acquiring the necessary components. At present, a bearing repair kit for Samsung washing machines can be found on the market. There in one package go immediately:

- bearings;

- oil seals;

- special grease.

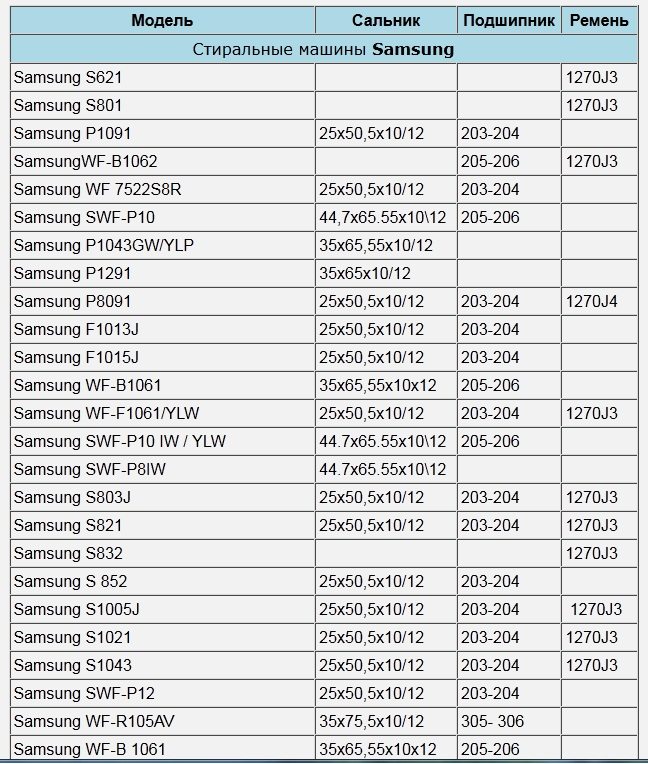

True, there is one snag Repair kits are available for different models of washing machines, so in order not to accidentally mix anything up, you need to know which bearings are suitable for which model of washer. To prevent mistakes, experts have prepared a table of accessories for the Samsung washing machine. Having familiarized yourself with it, you will be able to accurately acquire the original bearings and begin work on their replacement.

In addition to components, we also need tools. For the dismantling of fasteners, the promotion of the tank, knocking out bearings, we need:

- copper malleus;

- special grease for the elements of the washing machine or liquid WD-40;

- hexagonal key;

- marker;

- steel stud or metal tube;

- pliers or pliers;

- small adjustable wrench;

- keys (spanners and heads);

- screwdriver indicator, cross and flat;

- any sealant.

We take out the tank

We found the tools, purchased accessories, you can prepare a place for convenient work, and then proceed to disassemble the Samsung washing machine with your own hands. At the second stage, our task is to remove all the "excess" from the washing machine, so as not to interfere with dismantling the tank. You need to do this in such a way that nothing breaks or gets lost, so put all the removed parts in separate piles. So, we begin disassembly.

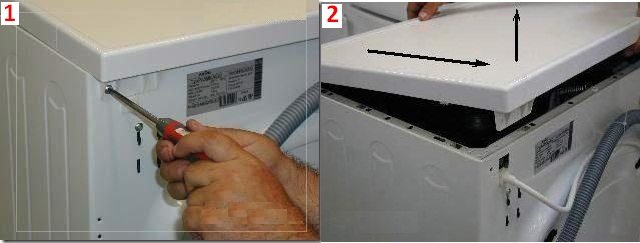

First, remove the top wall (cover) from the machine. To do this, unscrew the two fasteners that hold this cover. They are located at the top of the back wall at the corners. Then you need to put both palms on the top wall and pull it towards you, and then lift it up.

Next, take out the powder cuvette. This is necessary so that water does not spill out of it and does not flood the electronics at the moment when we will tilt and turn the machine. Removing a cuvette is simple:

- you need to open it all the way;

- with the finger of one hand press on the “tongue” of the central section;

- at the same time, with the second hand, slightly raise the cuvette and pull it towards you;

- if everything is fine, the cuvette should pop out and remain in your hands.

Having removed the powder cuvette, we unscrew the water supply hoses in its section, as well as the hose through which water and powder enter the tank. Remove the hoses carefully so as not to damage the clamps. Unclip the clamps with pliers, and then tighten the hoses.

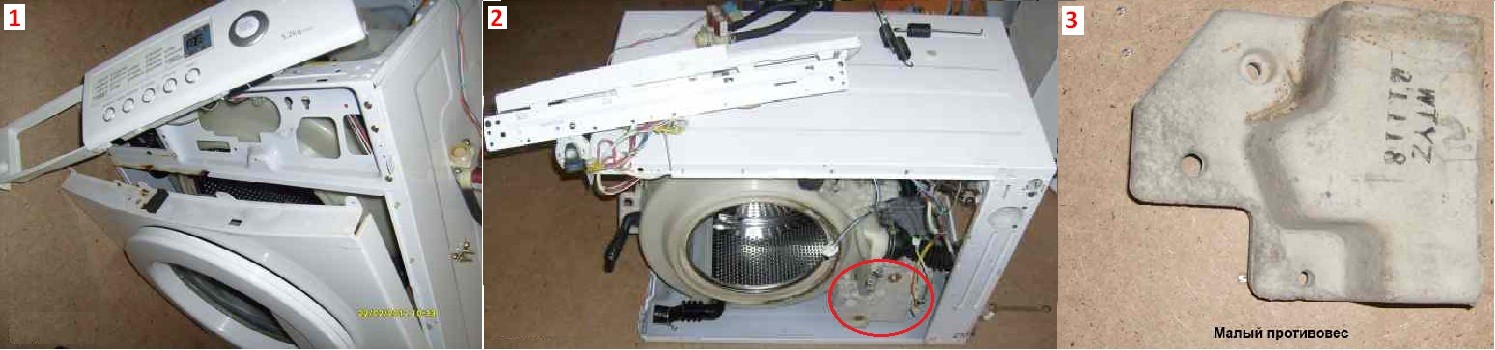

Further, our task is to remove the large upper counterweight that bothers us. To do this, take the head of a suitable size and unscrew the two fasteners, then gently holding the counterweight, take it out and remove it to the side.

Important! When unscrewing the last bolt with your hand, be sure to hold the counterweight with your second hand, because it is very heavy and can slip to the side, damaging important parts of the Samsung machine.

Now go to the front wall of the Samsung washing machine. We need to remove it with our own hands, but for this we will have to correctly dismantle the rubber cuff without damaging the element of the hatch blocking system.What needs to be done?

- We unscrew the two fasteners of the hatch blocking device.

- Then disconnect its sensor so as not to tear the wire when removing the cuff.

- Screw the bolts back so as not to lose.

- We take a screwdriver, find a steel cable clamp at the base of the cuff and pry it.

- We hold a screwdriver under the clamp, pulling it off the groove. Our task is to find the fastener of the clamp in order to loosen and remove it.

- Weaken the bolt and remove the clamp from the cuff.

- We put our fingers under the cuff of the hatch and gently pull it onto ourselves.

You can not pull out the cuff to the end, the main thing is that it does not interfere with removing the front wall. For a while, we leave the front wall alone. Now we need to put the Samsung washing machine on its side to remove its bottom. To do this, unscrew the four fasteners that hold the bottom cover and remove it.

Now let's do the electrics. It is necessary to disconnect all wiring from the electric motor of the Samsung washing machine, as well as from the drain pump. It would be nice to shoot the process of working with an electrician on video, because the wiring is easy to get confused. If this is not possible, then you can simply make notes using the marker.

Note! The contacts connecting the wire to the sensors of the units are rather flimsy, so try to be careful. If a burned-out wiring is found or the contact should be replaced immediately.

We proceed to dismantle the racks on which the washing machine tank lies. To do this, unscrew the four fasteners that secure one end of the rack to the tank, and the other to the bottom of the case. In the lower part, we will not unscrew anything more than the engine, the drain pump will not hurt us, we just need to disconnect the pipes from it.

Leaving the machine on its side, we pass to its upper part. Now we need to dismantle the filler valve together with sensors and nozzles. Disconnect the wire going to the valve sensors, and then unscrew the bolts holding it. After that, take out the valve and remove it to the side. We disconnect the balances, which are four springs on which the tank is suspended.

The road for the tank to exit through the upper part of the hull is almost “cleared”, it remains to remove the front panel and the wall. Unscrew the five screws that hold the front panel and remove it. At the same time, try not to damage the control unit by tearing the wires. Next, unscrew the front wall, unscrewing a total of 10 fasteners, and remove it to the side. In front under the tank we will see another small counterweight, it also needs to be unscrewed so as not to interfere.

Everything that could interfere with the extraction of the tank, we turned off, now you need to very carefully pull the tank out of the housing of the Samsung washing machine along with the engine. Removing the tank, drum and engine is a very crucial moment, you can touch some contact and then the work will increase. Turn the tank over, remove the belt from the pulley, and then unscrew the pulley with the hex key.

Note! The fastener holding the pulley can “stick”, therefore, in order not to exert unnecessary efforts, risking to break the thread, lubricate the bolt with WD-40 grease.

The tank is removed, now you can proceed to the next stage of disassembly. The process of disassembling the washing machine for a beginner may seem complicated, so we recommend capturing it in a video, so that later you can see where it is inserted and screwed on.

The tank is removed, now you can proceed to the next stage of disassembly. The process of disassembling the washing machine for a beginner may seem complicated, so we recommend capturing it in a video, so that later you can see where it is inserted and screwed on.

We unwind the tank and change the bearings

We proceed to disassemble the tank of the Samsung machine and remove its drum with our own hands. We removed the racks on which the tank is located by unscrewing the fasteners connecting them to the tank body. These elements are designed to hold not only the racks, but also connect the two parts of the tank body, so we have already unscrewed the main connecting elements, it remains to remove the brackets and clamps. Staples and clamps can be pulled off with a screwdriver or open-end wrench, there are no problems with them.

Remove the upper part of the tank body and expose the drum. Now remove the bottom of the case. It turned out three large elements:

- the upper part of the tank body with a manhole in the middle;

- the lower part of the tank body with a heating element;

- drum housing with an axis.

Do not focus only on bearing repair. Check along the way and other elements of the machine, so that later you do not have to disassemble it in a new way. In particular, it would be nice to check the inside of the tank and the heater for scale. If she is there, she needs to be cleaned immediately. Ten must be cleaned, you can check it at the same time with a multimeter. If there is a problem ten needs to be replaced.

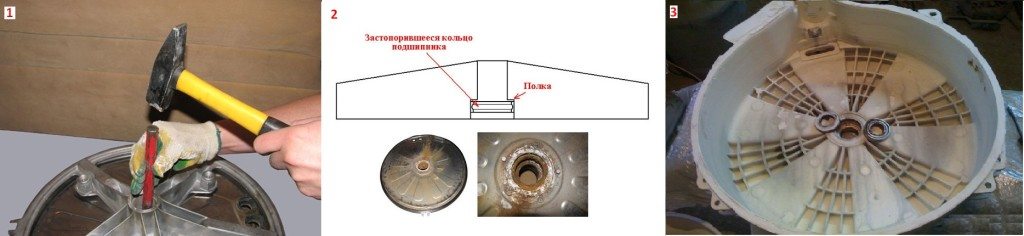

We proceed to the extraction of bearings. In the aluminum sleeve of the tank body there are two bearings, large and small. A large bearing should be knocked out from the inside into the tank body with the help of a pin; a small bearing is knocked out from the inside from the inside out. We take the pin, put it on one edge of the bearing and apply a light blow with a hammer. We put the pin to the other edge and again apply a light blow and so on in a circle until the bearing pops out.

Important! When knocking out a bearing, never beat at one point. Beat in turn at three or four points, otherwise the bearing will go crooked and become stuck in the sleeve, and this is already a problem.

We remove the used oil seals, carefully wipe the sleeve from the inside with a clean cloth. We take new oil seals, lubricate them with special grease from the repair kit and insert them into place. We take the bearings and put them in place until they hit the shelves. Bearings need to be planted as follows:

We remove the used oil seals, carefully wipe the sleeve from the inside with a clean cloth. We take new oil seals, lubricate them with special grease from the repair kit and insert them into place. We take the bearings and put them in place until they hit the shelves. Bearings need to be planted as follows:

- put the bearing in the sleeve and try to put it with your fingers as much as possible;

- take a wooden block, put it on top of the bearing;

- apply a few blows to the bar with a hammer until the bearing sits in place.

That's all, the replacement of the bearings was successful. Now we just have to assemble the washing machine in the reverse order. This is where the video that we shot, disassembling the car or marker marks comes in handy.

Typical mistakes "homemade"

Trying to independently replace the drum bearings of a Samsung washing machine, "Homemade" often make mistakes that, as a result, complicate the repair and require additional costs for it. What are these errors?

- Tearing the wire that goes to the sensor blocking the hatch.

- Cuff gap of washing machine hatch.

- Damage to the pulley, in the process of removing it from the axis.

- Failure of fixing bolts.

- Tearing wires going to the temperature sensor and heating element.

- Tearing off the nozzles due to the fact that they are not sufficiently loosened or forgot to loosen the clamps.

- Knocking out the bearings from the drum, they break the sleeve, and it all ends with the replacement of the drum.

You need to know about these typical mistakes and never repeat them, because replacing a drum is a serious expense, and maybe even worse.

In conclusion, we note that changing the bearings that ensure the rotation of the drum of a Samsung automatic washing machine with their own hands is not easy, but possible. The main thing is to find out what bearings are on the typewriter of your model, buy original accessories, pick up the necessary tools, and then, "rolling up your sleeves," perform the work in accordance with the instructions of the specialists outlined in this article. Have a good repair work!

Interesting:

How to disassemble a Zanussi washing machine

How to disassemble a Zanussi washing machine How to change the bearing in the LG washing machine

How to change the bearing in the LG washing machine How to change the bearing in an Indesit washing machine

How to change the bearing in an Indesit washing machine Replacing the bearing in a Zanussi washing machine

Replacing the bearing in a Zanussi washing machine The washing machine drum hangs and staggers

The washing machine drum hangs and staggers Do-it-yourself disassembly of the Ariston washing machine

Do-it-yourself disassembly of the Ariston washing machine

20 reader comments

Add a comment Cancel reply

Headings

Washing machine repair

For buyers

For users

Dishwasher

The video is very good, it helped to replace the bearings.

I support the previous comment. It really helps, the details certainly differ, but the principle is well stated. If you know how to handle appliances and there is a parts store for household appliances - you can try.The only thing to be patient is, because the process will be delayed (I suppose the bearings were knocked out with strain), again, while you remove the heaps of dirt inside ... But in general, I am satisfied. A pair of bearings, an oil seal and grease cost 1,200 rubles, not bad, given the alternative to the master for 7,000 rubles.

Tell me, did you change the sealing ring of the drum? Or put a gasket on the sealant?

In the video, they recommend changing the gasket-ring of the tank. And it costs 2900r.

Very accessible and understandable. Great help. Thanks to the author of the video.

Sorry, I was led astray. 2900t.r. there is a cuff. And gaskets do not sell at all. I recommend having ties for small bearings for this toolbox. And then it took about two hours to remove the 204 bearing from the activator shaft - a chisel and other stray. The activator did not come out with a light blow of the hammer. I had to use force that the bolt was bent, and the internal bearing remained on the shaft (attached). It is necessary to remove carefully so as not to damage the seat of the gland and not to break the silumin cross of the activator. I had to torment - although I am an electrician of the 6th category. Bearing removal experience is available. Before mounting the bearings, grease the seats and the shaft with grease and everything will turn out easy and simple. When working, there are always unforeseen ambushes, which are indispensable. For the video of course grateful. Thank! Repair cost 1000r. + beer after work. Good luck master!

Hello. the big bearing is not beaten out. What to do?

Did you get out? Share how!

The hammer did not work, the punch helped in the blow mode. Recommend.

Very nice video! Everything worked out!

Good video. Thanks to the master.

Very detailed and affordable. Thank.

The video helped, the master explained everything easily. The ambush was with an oil seal, rotted completely. I had to suffer while I cleaned the seat. The bearings came out pretty easy. New ones entered without any problems. The hardest part was finding a repair kit. In service centers, not everyone wants to sell even the simplest - grease for oil seal.

If they don’t sell, it means they have little work, here they sell easily!

In the course of removing the rotten gland, it loosened the installation space under it. There is no way to press in a new oil seal; it is easily inserted and removed by the hand. Is there a proven way out?

Thanks for the video. Very helpful!

The video really helped! Thank!

Thank you for the video. Everything is very accessible and understandable.

A true professional in his field. Such a master would entrust repair of anything. Thanks for the detailed repair instructions.

Everything turned out to be carried out by analogy, the only pressing of the bearing was entrusted to the master for 500 rubles.

Thanks to the master!