Wind generator from the washing machine engine

Today, many are interested in alternative sources of energy, but this does not go beyond reasoning and ideas, since such sources of fabulous money cost. For example, a 2.5 kW wind generator together with a gearbox and a screw will cost 60 thousand rubles, not including the installation fee, to put it mildly, a little expensive. But it is not necessary to give up the idea due to lack of money, you can make a wind generator with your own hands from parts of the washing machine, and we, in turn, will share with you the experience of manufacturing this thing.

Today, many are interested in alternative sources of energy, but this does not go beyond reasoning and ideas, since such sources of fabulous money cost. For example, a 2.5 kW wind generator together with a gearbox and a screw will cost 60 thousand rubles, not including the installation fee, to put it mildly, a little expensive. But it is not necessary to give up the idea due to lack of money, you can make a wind generator with your own hands from parts of the washing machine, and we, in turn, will share with you the experience of manufacturing this thing.

Do I need to take on the manufacture of a windmill?

Everyone needs to answer the question whether or not a wind generator is needed, everyone must for himself. But if the question is acute and there is only a dilemma to buy a windmill or do it, we will give you specific numbers. A Chinese-made wind generator assembled “with all the giblets” and installation (what is called “turnkey”) will cost you 75,000 rubles and this is at pre-crisis prices. A self-made wind generator from a washing machine will cost an average of 3,500 rubles (maybe a little more expensive if there is a "strain" with scrap metal). As the saying goes, feel the difference.

Of course, it’s not only about money that it will take a lot of time, ingenuity and “golden hands” to “bring to mind” a homemade wind generator, but in general the result is worth it, because at the output you get a stable device with a power of 2.5 kW. This is enough to at least electrify a small cottage. In particular, our windmill provides lighting for two rooms of a country house, a computer and a small portable TV.

Note! In order for the efficiency of the wind generator to be as high as possible, you must immediately consider the place of its installation. The ideal option is an open space.

We select the necessary parts

As already mentioned, in the presence of a garage full of various metal rubbish, the cost of manufacturing a wind generator from the engine of a washing machine with its own hands is sharply reduced. The main element that you need to deal with first of all is the generator. The generating unit is the basis of your homemade windmill, but it is, at the same time, its most expensive element.

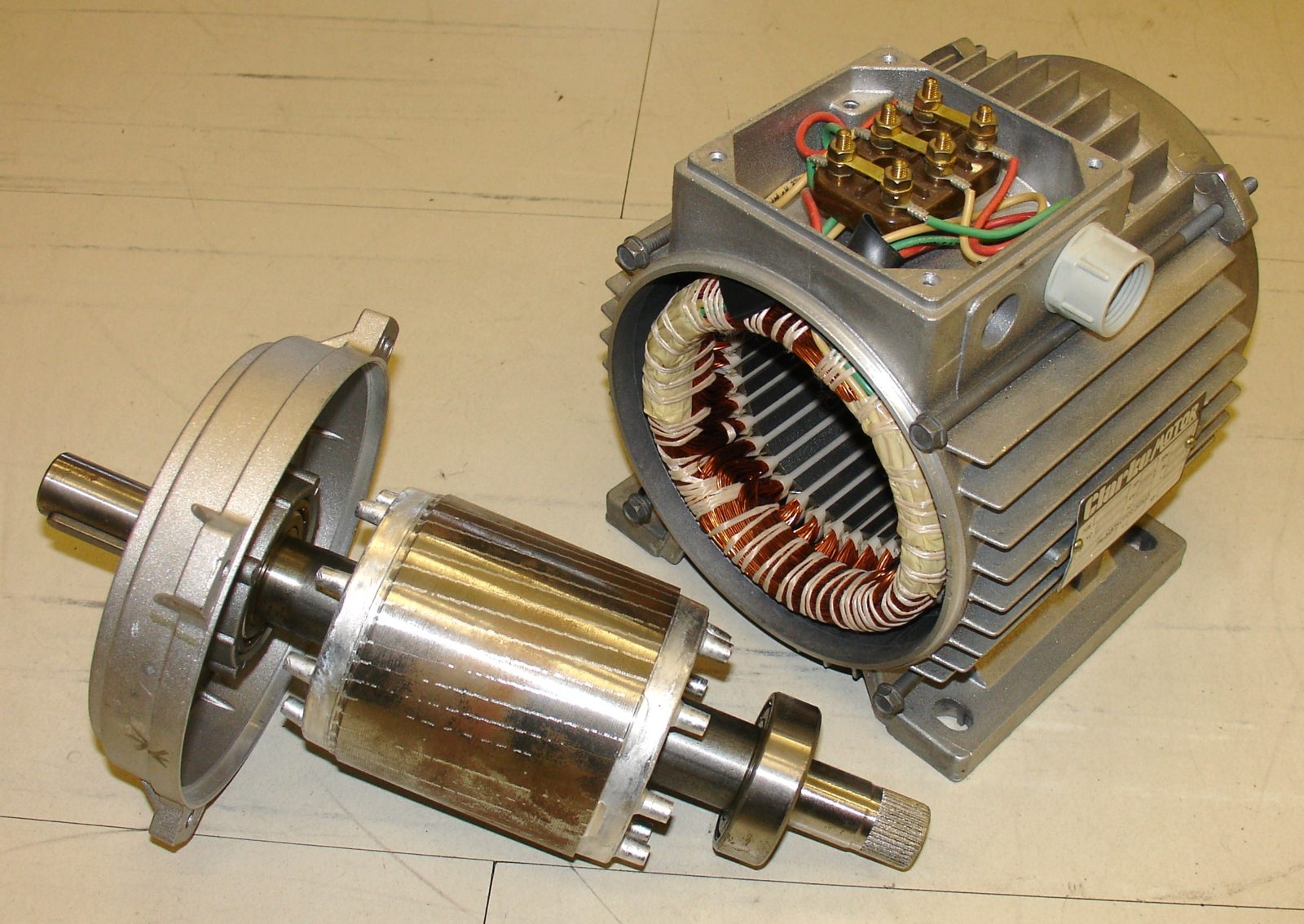

Some "homemade" offer to make a generator from the engine of the washing machine. There is a reason for this, but there is also a problem. This engine will have to be redone, namely, equip it with a magnetic rotor. There are two ways, the first is to buy a magnetic rotor, the second is to make. We offer not to bother, and order a finished rotor, why?

- For a home-made rotor, special neodymium magnets will be required, which will have to be ordered anyway. And the price tag for a set of such magnets is the same as for the new Chinese-made magnetic rotor.

- Assembling a do-it-yourself magnetic rotor with your own hands is fraught with certain problems. It will be necessary to cut out a special shape, and stick each magnet very securely - this is an ungrateful and painstaking job.

- The magnets on the rotor must be positioned at the right angle, otherwise they will stick, and the generator will stop working. It is difficult to calculate this angle, and it’s hard to fix magnets in this position.

Note! The magnetic rotor for the future generator is the main part of the costs, with the transfer it will cost about 2-2.5 thousand rubles.

A 2.5W magazine rotor is ideally suited to the engine from a modern washing machine, there is nothing even to be redone there. To say the word, from the engine of the washing machine you can make not only a wind turbine, but also, for example, grain mill, But that's another story. Next, you need to acquire a mast, gearbox, long shaft, gears and impeller.We assume that in the presence of certain materials, technical solutions may be different, in our case the mast was made like this:

- Several sections of 32 mm used steel pipes were taken and interconnected to form a single hollow structure 10 m long.

- Next, the mast was painted white.

- After that, the mast was ready to be lifted onto a pole. On it we secured protruding steel mounts from a corner with a hole so that the mast was held vertically securely, at the same time so that nothing would prevent its rotation.

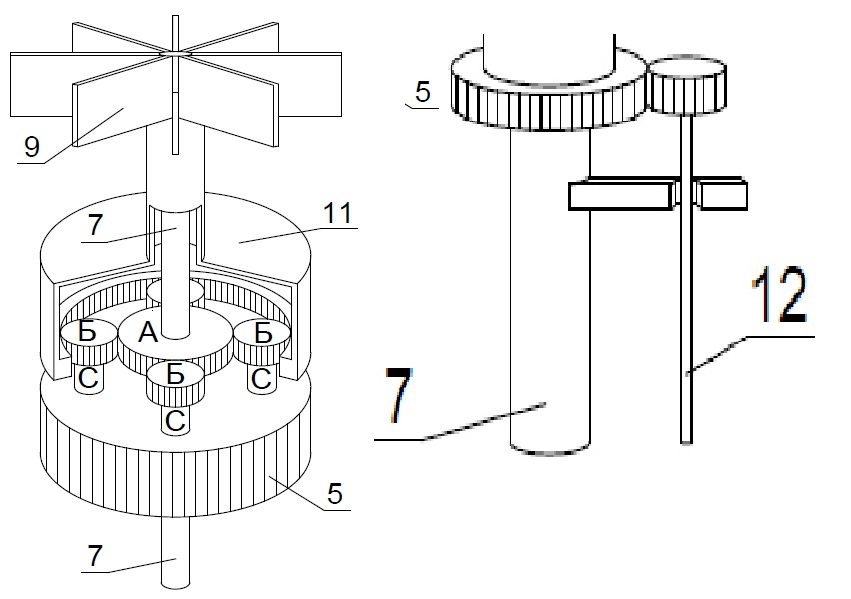

If there is no dysfunctional column nearby, then it will be necessary to solve the problem of support for the mast, since the pipe structure is unstable in itself. Next, we assemble the gearbox for a wind generator with a vertical axis of rotation, which is shown in the figure below.

- The main gear (5), dressed on the mast, was taken by us from the drive of the water pump.

- In a circle on the gears, the turned-off cuttings of the reinforcement are welded, they are the same axis (C) - 4 pcs.

- Bearings with gears (B) are pressed onto the axis.

- A small gear (A), dressed on a mast, from the same water pump is in contact with the gears (B), at the same time, they interact with the teeth of the gear housing along the edges of the gear (B).

The peculiarity of this design of the gearbox is that its body rotates around the mast completely freely with the propeller. Thanks to this, the speed of rotation of the propeller slows down somewhat, which affects the efficiency of the windmill, but the design becomes more stable and durable. Even with a hurricane wind, the wind generator will not break due to the gearbox that controls the propeller speed.

The “stumbling block” may be the gear housing (11), from which it can be made. A specific bottle-shaped casing with teeth in a circle should have suitable dimensions. We got out of the situation by adapting the steel casing of the electric motor from an industrial pump, we did not even have to cut the threads. The dimensions of the gearbox have already been designed for its dimensions. You can do the same or make the case yourself by size.

Important! To make the gearbox housing, specialist assistance is required, therefore, to save money, try to adapt ready-made housings from old engines and pumps.

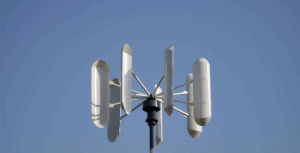

Another difficulty is to make the impeller. By the way the impeller will not be located perpendicular to the earth's surface like most industrial windmills, but horizontally, as this makes the structure simpler and more reliable. This does not require a device that will direct the impeller in the wind. With this it is clear, it is clear that the impeller must be rigidly fixed to the rotor body, but how and from which to make it? With this, we had a whole "epic."

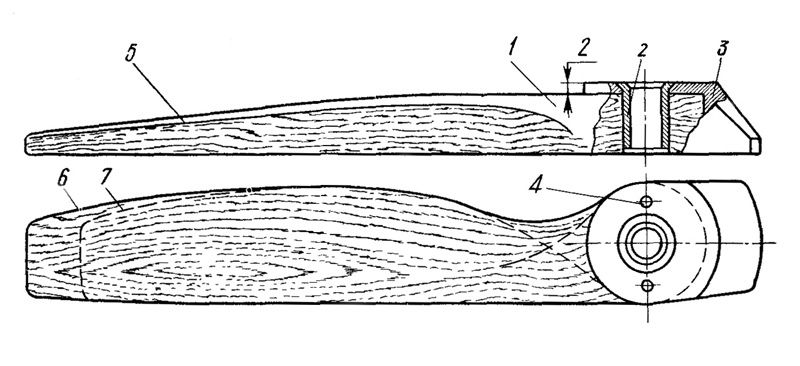

- First, we made the impeller blades from five-layer plywood. Maybe this material would have come up if the blades were shorter. But since our design implies a blade length of at least 1.5 meters, and preferably 2 m, the plywood propeller broke due to gusts of 10-15 m / s.

- Solving the problem of how to make the propeller light and durable, we used fiberglass trimmings, which friends gave us. It is a very durable material, but at the same time flexible. To ensure structural rigidity, we had to cut out not three rectangular strips, but six and glue them together. And only then to connect the strips into the impeller with a length of each wing of 1.6 m. The impeller turned out to be very durable, it even survived the storm with a wind speed of 37 m / s.

- While making the fiberglass propeller, the idea ripened to make a propeller of another (orthogonal) type, as shown in the picture below. The basis of the construction of a light duralumin corner is crowned with large ovals of painted tin blades. Unfortunately, the idea could not be realized due to lack of time, but you might want to do something similar.

Next, we need a small gear and shaft (12, on which it is pressed. We fix the shaft in special mountings so that it does not pop out, while at the same time rotates freely. And the last thing we need is a flange for connecting the rotating shaft to the generator. We will make a shaft from reinforcing bars welded together.

Some will ask, why such difficulties, some kind of rotor with a bunch of gears and gears? In fact, everything is completely justified, since in most of the territory of Russia there is a very uneven wind load. The wind often changes direction and speed, which negatively affects the mechanism of a standard wind turbine, which will often break, and this is unacceptable. Our proposed mechanism of a windmill from the washing machine engine is much more stable and will work for a long time with high-quality performance.

Do-it-yourself windmill

The design concept is defined, spare parts are selected, a drawing is made on their basis. Now you can start collecting the windmill from the washing machine engine. First, determine the location of the windmill. The support should be placed in an open windy place, preferably on a hill. The height of the support should be as large as possible, in our case (as we have already said), we used a wooden electric pole 10 meters high, disconnected from the communications, located on our land plot. Next we do the following.

The design concept is defined, spare parts are selected, a drawing is made on their basis. Now you can start collecting the windmill from the washing machine engine. First, determine the location of the windmill. The support should be placed in an open windy place, preferably on a hill. The height of the support should be as large as possible, in our case (as we have already said), we used a wooden electric pole 10 meters high, disconnected from the communications, located on our land plot. Next we do the following.

- We install the mast on a support, on special mounts. During installation, we used mounting claws.

- We install the previously assembled gear with the impeller on the mast, we are convinced of its performance.

- We connect the shaft to the main gear (5) located on the mast at the base of the gearbox.

- We fix the shaft in the special fasteners described above.

- We connect the rotating shaft with a generator, which even earlier must be fixed on a steel support, welded from corners vertically directly opposite the shaft. The support can be made any, if only it reliably held the generator.

- To prevent the generator from wetting with rain and falling asleep with snow, you can build something like a booth or a durable canopy over it. In this case, it will last much longer.

So we described in general terms the process of creating a wind generator from the engine of a washing machine. Now you can begin to test it, we hope it will help you take another step towards the autonomous power supply of your summer house or private home.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment