DIY Daewoo washing machine repair

Korean washing and drying equipment has won the trust of consumers due to the high build quality and reliability of the equipment, combined with an attractive price. However, no matter how durable the machines are, over time, their individual elements can fail. We will figure out how to repair the Daewoo washing machine and quickly fix the identified malfunction.

Korean washing and drying equipment has won the trust of consumers due to the high build quality and reliability of the equipment, combined with an attractive price. However, no matter how durable the machines are, over time, their individual elements can fail. We will figure out how to repair the Daewoo washing machine and quickly fix the identified malfunction.

Self-diagnosis system

Most modern Daewoo washing machines can independently diagnose breakdowns that occur in the system. Thanks to electronic control, the equipment finds the problem and notifies the user about it, displaying a specific error code on the display. Semi-automatic machines that do not have a screen notify the hostess of a malfunction by blinking an indication on the control panel. Consider the most common failures that occur with Daewoo units, and their code designation:

- OE - an error reports problems in the drain system. A possible cause of a malfunction can be a malfunction of the water pump, damage to the supply wires leading to the pump. Do not exclude the possibility of clogging of the trash filter and other parts of the drain system. Alternatively, the drain hose is not connected correctly or is kinked too much.

- IE - the code reports a very slow or not at all carried out water intake into the tank. In most cases, this designation does not indicate problems in the machine system. You may have forgotten to open the inlet valve, as a result of which the washer cannot draw water. Also, the reason may be insufficient water pressure in the water supply. If this is not the case, check the inlet hose for kinks and blockages, rinse the filter located on the inlet pipe. Much less often, the code signals the failure of the pressure switch, which regulates the level of water intake.

Do not rule out a malfunction of the solenoid valve.

- UE - an error may appear on the display during the washing process and talk about the imbalance recorded in the drum. Another reason for displaying the code is the improper installation of the machine, for example, if the washer is placed on an uneven surface, is not level. Very rarely, a designation indicates a defect in balances.

- LE - says that the hatch did not close tightly. There may be a breakdown of the door lock device. Also, the hatch could squint due to wear on the hinges.

- E8 - the code is typical for machines equipped with a boot sensor. The error indicates a malfunction of the measuring element and the need to install a new load sensor.

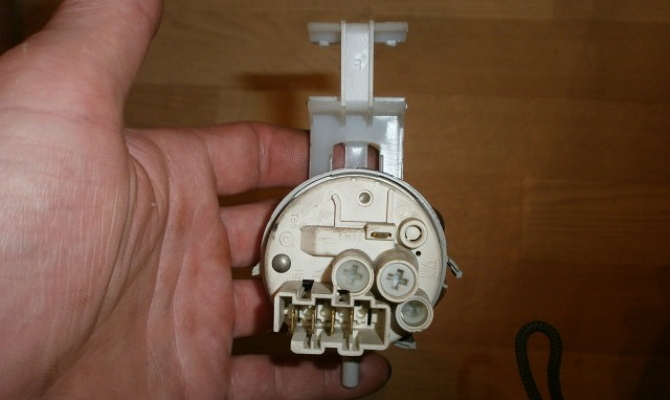

- E9 - this designation on the Daewoo display will tell about the failure of the pressure switch or the breakdown of the level switch. It is necessary to check the hose leading to the water intake sensor, to make sure the connection of the pipe to the element is tight. You may need to replace the pressure switch.

- H6 - an error warns of an open circuit in the heater. In most cases, the heater breaks down; in this situation, the element will have to be replaced.

If you have an idea about the codes of frequent breakdowns, you can significantly save time on diagnosing the washing machine. The designation of an error significantly narrows the scope of troubleshooting places that have occurred in the system.

Typical failures and their causes

After evaluating the error codes listed, you can understand which components and parts of Daewoo washing machines are the most vulnerable. As in cars of any other brand, the heater most often suffers, the liquid level sensor, the drain filter is clogged. In addition, owners of SMA Daewoo face the following problems:

- malfunction of the main control module. Many factors can signal this, for example, premature stop of the washing process, or, on the contrary, too long program execution;

If the machine does not wring things, it can also warn of a malfunction in the electronics.

- clogged filter mesh in the water intake hose;

- failure of the temperature sensor, as evidenced by insufficient heating of the water or the cessation of the functioning of the machine when washing;

- rupture of the drive belt;

- leakage from under the hatch door due to a worn sealing collar, etc.

The listed breakdowns are typical for vertical bars and front-ends of the Daewoo brand. The named elements are vulnerable in all models of washing machines. To the "sore" place of the washing machine can also be attributed drum, amenable to rust and wear.

To extend the period of maintenance-free use of a Daewoo automatic machine, you should warn:

- quick natural wear of components;

- intake of too hard and polluted water into the system;

- power surges;

- bad quality detergent in the dispenser.

It’s quite possible to fix some types of malfunctions with your own hands. Before you begin, you need to carefully understand the problem and really assess your strength. We will analyze how to eliminate the most common breakdowns.

Repair a water level sensor

A signal of a malfunction in the pressure switch can be slow intake of water into the system or liquid not entering the washer. It is necessary to access the part and examine it for damage. The algorithm of actions will be as follows:

- remove the top cover of the unit body;

- find the pressure switch on the wall of the machine, near the lid mount;

- disconnect a branch pipe from the sensor. For this, pliers may be needed;

- replace the hose, blow a thin tube into it. When the pressure switch is in good condition, clicks should be clearly heard;

- Examine tubes for defects.

Having found damage on the tubes, it is necessary to replace the nozzles, revealing a blockage - clean. When sticking the tubes will have to change the pressure switch completely.

Eliminate water problems

This type of malfunction can also be dealt with on your own without resorting to the help of a wizard. In most cases, it will be sufficient to flush the water filter and the inlet hose directly. The work is carried out in the following sequence:

- get access to the back wall of the machine;

- disconnect the water intake hose;

- at the end of the pipe you will find a filter mesh that needs to be removed and cleaned well;

- additionally inspect the inlet hose, rinse it with water.

Having collected the machine back, you should start a test wash. If the cause of the error is still not resolved, you will have to inspect the equipment inlet valve and, if necessary, change it. If you can’t cope with the problem on your own, it is better to contact professionals.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment