How to check the level sensor in an LG washing machine?

If the washing machine does not wring out, does not type completely or threatens to flood the apartment, then the pressure switch is to blame for 80%. You cannot start the problem - you need to call the wizard for diagnostics or start the repair yourself. It is not difficult to check the water level sensor on the LG washer yourself: just find the device and perform a couple of actions. What exactly needs to be done?

If the washing machine does not wring out, does not type completely or threatens to flood the apartment, then the pressure switch is to blame for 80%. You cannot start the problem - you need to call the wizard for diagnostics or start the repair yourself. It is not difficult to check the water level sensor on the LG washer yourself: just find the device and perform a couple of actions. What exactly needs to be done?

Verification Instructions

No reason to climb into the machine is not worth it. Before diagnosing the pressure switch in the LG washing machine, it is worth checking for certain signs of a faulty water level switch. Damage is not without consequences, therefore, the unit will let the owner know about the problem with the following signals:

- the drum rotates or the heater turns on without water in the machine;

- insufficient or excessive set of the tank is noticed;

- in rinse mode, the water is pumped out and refilled;

- smell of burning;

- fuse on the heating element is activated;

- there is no spinning of linen.

Even one “symptom” present is a signal for diagnosing a pressostat. But you cannot blame only the level switch for problems, since other malfunctioning parts can lead to similar troubles. To eliminate the error, we take out the sensor and check it for operability.

For safety, the manufacturer of the LG washing machine installs fasteners with special heads near the pressostat, so it is important to arm yourself with a special screwdriver with interchangeable nozzles.

- We unscrew the two screws holding the top panel at the back of the case.

- Press the lid away from you and remove it.

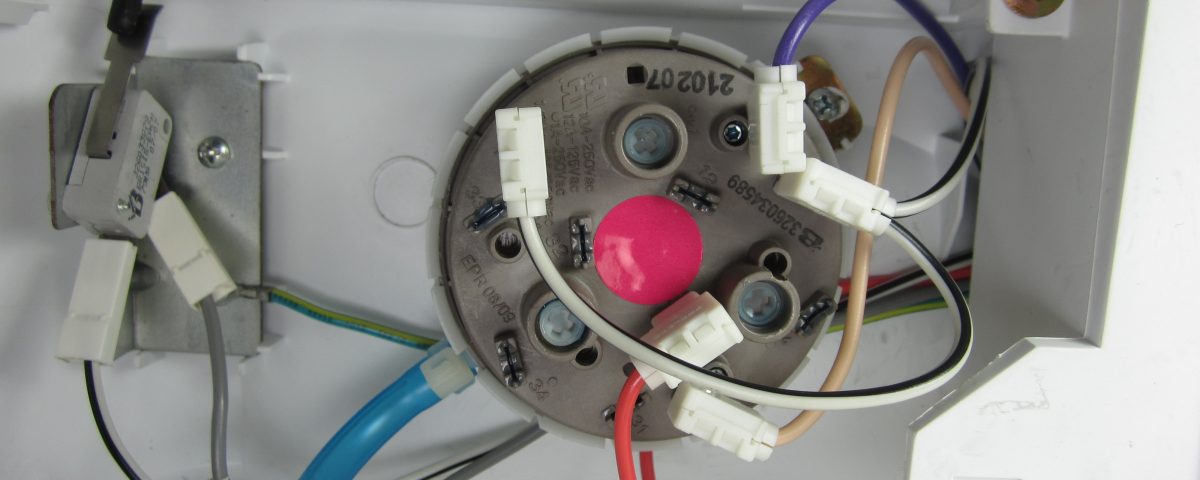

- We find a rounded plastic box of black or white color near the side wall - this is the pressure switch.

- Disconnect the wiring and pipes from the sensor.

- We loosen the fixing bolts and pull out the housing with a long tube extending into the tank.

Having taken out the sensor, we begin inspection. First of all, we evaluate the condition of the tube visually: there should be no damage and blockages, and the external slats on the connectors can only be clean and not oxidized. If problems are noticed, corrosion, oxidation or contamination, the relay is carefully cleaned and flushed. After proceeding to a direct check:

- we find a hose or tube commensurate with the opening of the pressure switch fitting;

- we put the tube on the fitting;

- we bring the block to the ear, and the end of the hose to the mouth;

- blow into the hose and listen for a click. There are usually two or three clicks, but in some models a contact can be activated once. The main thing is that there should be no silence, which signals a faulty pressure switch.

There is another way - to connect an ohmmeter or multimeter to the sensor terminals. If you close and open the contacts, the device must detect a sharp change in resistance. In order not to make a mistake when connecting to the connectors, it is recommended that you first study the wiring diagram in the factory instructions.

Set up the pressure switch

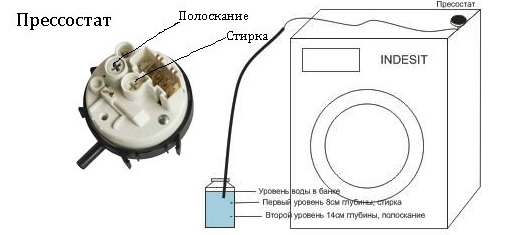

An idle pressure switch can be tried to “reprogram”. To do this, we adjust the two adjusting screws to a specific water level so that the one located in the center fixes the moment of contact closure, and the third - their break. In this case, there are several contact pairs, since various machine models require washing programs with different filling of the tank. For example, with a standard or delicate cycle, a full drum is taken, and when choosing an economy mode, only half.

Self-adjusting the position of the screws is extremely problematic. Full adjustment is carried out by professionals at the factory, and the corresponding marks are applied to the handset.It is strongly discouraged to change the set position, as the intervention threatens with a serious imbalance. The situation is complicated by the fact that the average user of the machine does not know how many liters of water the unit takes at each stage when you turn on any of the available programs. The more options the washing machine offers, the more difficult it is to reprogram the pressure switch.

How to change a part?

If there is no doubt about the malfunction of the device, it must be replaced. It is not possible to repair the pressure switch - the relay case is one-piece, and attempts to get inside the box will cause damage to the fragile internal mechanism. Moreover, the price of the device is low, and most of the device does not cost more than 200 rubles.

The choice of a new pressostat must be approached thoroughly. It must be exactly the same, match brand of washing machineup to the presence of a direct drive and accounting for tank capacity. Ideally, the sample is a removed relay, after which the sensor is checked by serial number and manufacturer. Preliminary testing of the device’s operability by the method described above will not hurt. The sensor unit is installed similar to dismantling, but in reverse order.

- First, fasten the relay with screws on the seat.

- We connect to the fitting by tightening the clamp.

- We bring wiring and pipes.

- We return the lid to the washer.

Anyone can cope with the diagnosis and replacement of the washing machine. The main thing is not to deviate from the instructions, be careful and at the end of the repair check the operation with a test wash.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment