How to fix F08 error on Virpul washing machine

Automatic machines Virpul are distinguished by build quality, reliability and high efficiency of washing; they serve their owners faithfully for a long time. However, not a single household appliance is completely insured against breakdowns. For example, a situation may occur in which the user starts the washing process, the machine starts to work normally, but after a while it stops and displays the error code F08. What this designation says, and what actions to take to fix the breakdown, we will talk further.

Automatic machines Virpul are distinguished by build quality, reliability and high efficiency of washing; they serve their owners faithfully for a long time. However, not a single household appliance is completely insured against breakdowns. For example, a situation may occur in which the user starts the washing process, the machine starts to work normally, but after a while it stops and displays the error code F08. What this designation says, and what actions to take to fix the breakdown, we will talk further.

What would that mean?

A similar code may appear on the digital display at any washing step. He says that the temperature of the water in the tank does not match the parameters set by the program. Such a malfunction on the Whirlpool washing machine can indicate both a small problem and a serious defect, which only a qualified craftsman can handle. It also happens that an error is highlighted due to a short-term failure, and in fact there is no breakdown.

Before you start repairs with your own hands or invite a specialist, you need to make sure that this is not a normal malfunction in the washing machine. To do this, follow these steps:

- restart the automatic machine: disconnect it, unplug the cord from the outlet, reconnect it to the mains and press the power button. In this way, about 80% of problems are usually solved, when you reboot, it is quite possible that the error code will disappear as unexpectedly as it appeared;

- if you changed the programmed parameters of the selected washing mode (heating temperature, spin speed), it is likely that the machine simply "is acting up" and does not want to put up with the inconsistency of the settings you set and the factory characteristics of the washing program.

If you rebooted the unit, made sure that even with the standard parameters of the washing mode the display shows this fault code, you should proceed with the search for damage. Where to begin?

Limit the circle of breakdowns

For heating the water in the tank of the washing machine, the heater is responsible for the tubular heater. In most cases, the designation F08 occurs precisely when the heater fails. If this is really the case, you must replace the part with a new one. But the failure of the heater is not the only reason for the appearance of such an error. Code may mean something else.

- Pressostat malfunction. The appearance of problems with the water level sensor can lead to uncontrolled intake and drainage of water by the machine. The liquid simply does not have time to warm up to the set temperature.

- Failure of the temperature sensor. When the thermostat stops functioning, the water heats up too slowly, or vice versa so quickly that its temperature at the moment becomes much higher than the set value. The temperature sensor will transmit "false" information to the central unit, and the control module will thereby give false commands to different systems of the unit.

- Defective electronic control module (controller), which is the "brain" of the washer. When it breaks down, malfunctions in the normal functioning of the machine are observed. Flashing or replacing the item with a new one may be required.

To begin with, you need to "weed out" the most minor and easily eliminated malfunctions. For example, to diagnose the heating element, after the pressure switch or temperature sensor, and only after checking that the reason is not this, call the master, who will be able to make a professional decision on the condition and operability of the control module of the Virpul automatic machine.

Check the heating element

Often error F08 appears as a result of a heater malfunction. You can check the heater very quickly.To do this, perform the following algorithm of actions (the sequence of steps described will help owners of machines with front-loading type, manipulations will be slightly different for vertical lines):

Often error F08 appears as a result of a heater malfunction. You can check the heater very quickly.To do this, perform the following algorithm of actions (the sequence of steps described will help owners of machines with front-loading type, manipulations will be slightly different for vertical lines):

- disconnect the washing machine;

- disconnect the drain and inlet hoses from the house utilities;

- provide yourself with consolidated access to the back of the washing machine;

- unscrew the bolts holding the back cover;

- unscrew the bracket covering the heater.

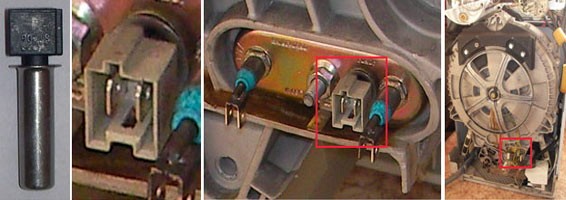

Important! The heater is located in the lower part of the machine, under a plastic casing, only by removing the protective pad can you access the contacts of the heating element.

Next, disconnect the power contacts, take the multimeter and connect its probes to the terminals of the heater, set the resistance to 200 Ohms on the device, analyze the results. If the value on the multimeter screen remains approximately the same as it was set, it means that the heater is fully operational. When the number 1 appears, this indicates a break in the part, and it will have to be replaced. When the number 0 is displayed on the device (or a number very close to zero) - this means that it is possible to diagnose a short circuit in the heater, in which case you will also have to install a new heater.

If the heater has passed the first test with a multimeter, just in case, check for breakdowns. To do this, put the test device in buzzer mode. The fact that the mode is selected correctly, you will be notified by a lighted bulb and a characteristic signal that will appear when the wires are connected. Connect one probe of the multimeter to the TENA terminal, attach the second to the element case. If the device does not make any sounds, everything is fine, if a characteristic squeak is heard - there are breakdowns on the part body, the heater will have to be changed.

Check the thermistor

If the heater fully passed the test, proved that it copes with its functions perfectly, it's time to check the thermistor. Just, it is located between the contacts of the heater. To remove the temperature sensor carry out the following operations:

- remove the chip with the wiring from the heater contacts;

- slightly loosen the nut that holds the heater;

- carefully remove the thermostat from the housing.

The temperature sensor is a small metal cylinder. After the thermistor is removed from the washer body, it is necessary to check the resistance in it using a tester.

- put the multimeter in resistance determination mode;

- hook the probes to the terminals of the temperature sensor. For example, if the temperature is 200 ° C, a resistance should be displayed on the screen, the value of which will be 6000 Ohms;

- immerse the thermistor in warm water, watch for changes in numbers on the device screen. In the case when the temperature sensor is working, the resistance will decrease, so at 50 ° C it will be about 1350 Ohms.

When the temperature sensor fails, replace the old part. The temperature controller is not subject to repair. If the item is fully operational, continue the diagnosis further.

We will examine and test the pressure switch

It is easy to provide access to the water level sensor of the Virpul washing machine, it is located in the upper part of the unit, directly under the cover. Very rarely, the pressure switch is located below. To get to the part, carefully disconnect the mounting screws and remove the upper wall of the SMA housing, after which the algorithm of actions will be as follows:

- prepare a tube, the diameter of which will correspond to the diameter of the pressure switch hose;

- disconnect the fitting by carefully loosening the clamp;

- attach a tube to the pressure hose and blow into it;

- when the pressure switch is working, you will hear 1 or 3 characteristic clicks;

- check the sensor for any damage;

- examine the fitting for blockages;

- When a blockage is found, flush the hose with a tap of water.

If, after an external examination, no defects were detected, you need to check the pressure switch with a multimeter.The device switches to resistance measurement mode, the tester probes are connected to the sensor contacts. If the values on the screen change, then the contacts are triggered and the pressure switch is working. When the resistance value remains fixed, it means that the fluid level sensor is out of order.

So, when checking the operability of the main elements that can provoke the error code F08, no malfunctions were detected, a professional should be invited to determine the root cause of the appearance of the code. After all, the problem may come from the main control board, and dealing with it on your own is not recommended.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment