Error E50 in the Electrolux washing machine

When the Electrolux brand machine suddenly refused to continue the cycle, the first thing we pay attention to the dashboard. For models with a display, a malfunction code will be displayed; for models not equipped with a screen, signal lights will begin to flash in a certain order. If the E50 error on the Electrolux washer is “to blame”, then we boldly begin the search for the problematic “core”. What and where to look?

When the Electrolux brand machine suddenly refused to continue the cycle, the first thing we pay attention to the dashboard. For models with a display, a malfunction code will be displayed; for models not equipped with a screen, signal lights will begin to flash in a certain order. If the E50 error on the Electrolux washer is “to blame”, then we boldly begin the search for the problematic “core”. What and where to look?

Initial action

If the Electrolux washing machine gives an E50 error code, then you should not immediately disassemble the case and look for a malfunction. This combination reports a whole range of problems, starting from the tachometer and ending with the control board. Therefore, the first thing we “ask” is a typewriter. We simultaneously hold down the “Start” key and the button adjacent to it until another cipher appears on the display. This is what you need to remember, as it will help clarify the nature of the problem.

You can fix the E50 error both with the help of a service center employee, and independently at home.

Also, the two-button method allows you to restart the machine. It is likely that there was a sudden system failure, and as such there was no error in the operation of the unit. You can restart the washer and the old fashioned way: turn it off and on.

Another common problem that provokes the appearance of the E50 combination is a non-functioning drain. Almost every owner of the machine knows what to do to correct this situation: we check for obstruction in the drain hose, in the trash filter and on the impeller of the pump. When the reboot and verification were unsuccessful, you will have to proceed further.

What caused the code?

You can’t stay idle - the problem that arises requires an urgent response, diagnosis and repair. But to make the correct "diagnosis" with an E50 error will not be easy. The difficulty is due to the large number of possible problems with the machine:

- short circuit control triac;

- failure of the tachogenerator;

- faulty motor;

- problems with the control board.

Error E50 signals problems with the tachogenerator, engine and control board.

The scope of the upcoming repair depends on the nature of the problem. Fast and inexpensive replacement is often required, but sometimes expensive control board firmware. In order not to guess, it is recommended to look for a malfunction sequentially, moving from simple to complex. First, we check the Hall sensor and motor, and last of all, we turn to the “brains” of the washing machine.

Check the tachometer

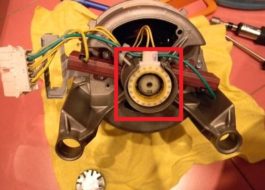

The tachogenerator is the first in the list for diagnostics. To check it and, if necessary, fix it, you must first find the device. There will be no problems with this: all washing machines, regardless of brand, model and year of manufacture, the Hall sensor is in the same place - on the motor shaft. Access to the device is a simple way.

- We disconnect the washing machine from the network, disconnect the drain and water supply hoses.

- We prepare screwdrivers and a multimeter.

- Unscrew the back panel of the case.

- Remove the drive belt.

- We find an electric motor.

- We draw attention to the small metal ring on the motor shaft - this is the Hall sensor.

It is impossible to remove the tachogenerator directly from the engine - first the engine is removed as a whole.

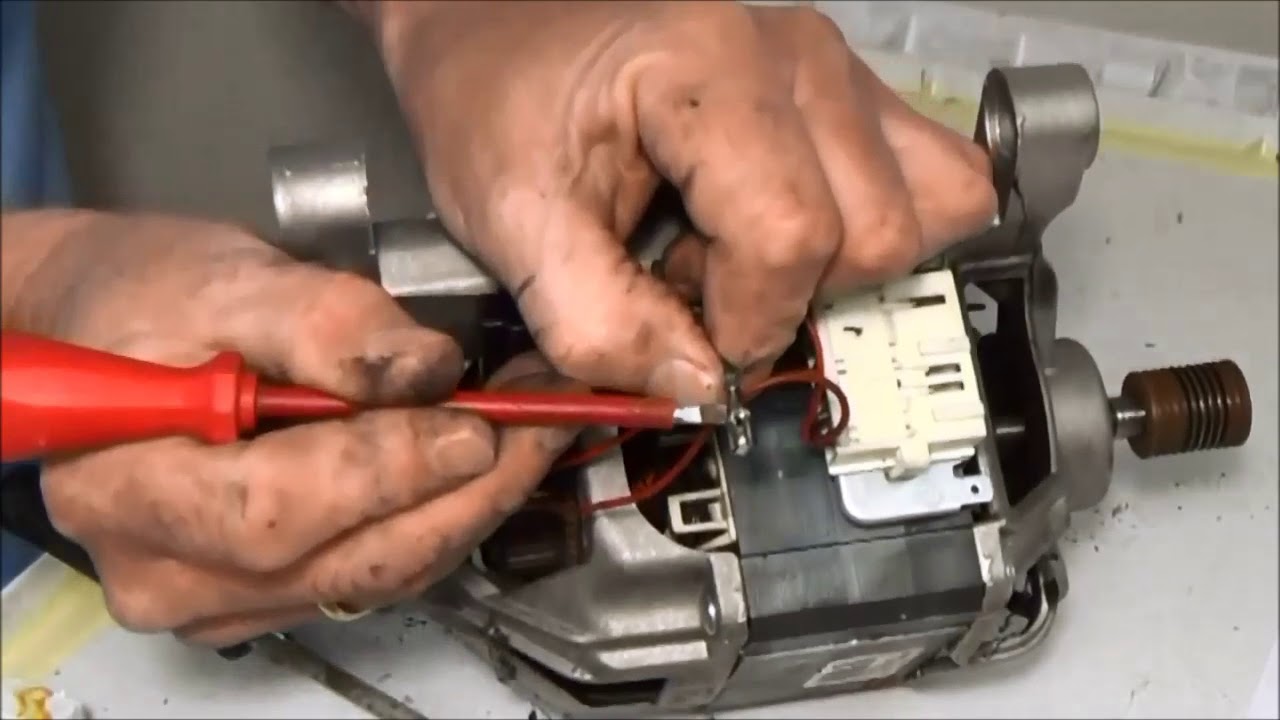

- We mark the wiring brought to the engine or fix all the phases on the camera, otherwise there is a high probability of an error in the connection and the engine being burned during reassembly.

- We unscrew the screws holding the engine.

- With two hands, swing the engine on the sides, and then sharply get it from the seat. It should be prepared for the fact that the part is very heavy.

As soon as the engine with the tachogenerator is in the hands, you can start the diagnosis. To begin with, we conduct a visual inspection: for the presence of external mechanical damage and the reliability of the mounts. Often, the latches in the terminals loosen or the contacts move away, and the solution to the problem is to restore the previous balance.

If visually everything is in order, then testing with a multimeter is ahead. There are two ways to test. In the first case, we configure the device to measure Ohms, after which we release the contacts and attach the probes to the bare contacts. Next, we evaluate the numbers on the display: if a value of 60-70 Ohms is displayed, then the sensor is working properly.

Another option is to measure the current generated by the tachogenerator. To do this, turn on the voltage mode on the multimeter, apply probes and accelerate the engine with your hand. If a value within 0.2 Volts appears on the screen, then the Hall sensor works. Otherwise, we replace the faulty device with a new one.

We carefully check the motor

If the tachogenerator is working properly, and the display on the Electrolux still shows the E50 error, then pay attention to the engine. To establish the cause of engine failure, it is necessary to conduct a comprehensive motor diagnosis. As a rule, the following elements of the system “fail”:

- collector slats;

- rotor and stator windings;

- electric brushes.

More often, "lamellas" suffer, which deteriorate after a short circuit in the windings. Due to current fluctuations, the contact plates overheat and exfoliate, which introduces an imbalance in the operation of the motor. “Layers” are fixed with adhesive solution directly on the collector, and the electrical connection occurs due to the formation of special hooks in the rotor section. Just the latter more often and becomes impossible if, due to a breakdown, a break in the cord occurred at the junction.

Many times worse when the lamellae exfoliate when heated. Then the current passing through the plates and the winding becomes higher than the operating level and can lead to unpredictable consequences. Peeling can be confirmed by slowly turning the rotor with one hand: if there is a clear crack, then there is a defect. Operation of such an aggregate is prohibited.

Exfoliation is not accidental. This leads to a bearing jam or the launch of the washer with half-open sashes during vertical loading. Also, through a similar defect, the lamellas “hint” at serious damage to the motor or improper operation of the machine. With a slight peeling up to 0.5 mm, the situation can be corrected by grooving the collector on a special machine. Do not forget about the control visual inspection, cleaning the body of chips and dust, manual cleaning of all irregularities.

Another problem spot on the engine is electric brushes. If they are erased, then the operation of the machine becomes risky. The fact is that when the carbon tips are worn, the “body” of the brushes begins to rub against the engine body, causing sparks to appear. To minimize the risk of fire, the old pair must be replaced with a new one.

Electric brushes change only by a pair - even if one of them has practically not been erased.

The choice of new parts should be taken very seriously. You can purchase a replacement through specialized stores, service centers or on the Internet. In the latter case, it is enough to enter the request into any search engine, select the organization you like, contact their support team, clarify the availability of spare parts or make an order. You can navigate in the assortment by the serial number of the washer, motor or the old model. There are no universal brushes - each engine requires "its own" tips. Hardness also matters, since too hard coals can ruin the collector.

If there are no problems with the brushes, winding and lamellas on the engine, there is only one option for failure - the failure of the control board. There may be several reasons for the malfunction, but self-diagnosis is not recommended. It’s cheaper and more reliable to immediately turn to professionals, since the electronic module is an extremely fragile and expensive system.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment