Error E3 in the washing machine Gorenje

Modern Gorenje models are able to conduct a system self-test and, in case of a problem, to warn the owner. The warning is displayed on the digital display in the form of a cipher - a code by which it is easy to identify the cause of the malfunction. Often, users of automatic devices from Gorenie encounter an E3 error, which indicates problems with the collection of water. The reason may be a banal shutdown of water, as well as a serious malfunction of the module. What exactly broke and how to fix the E3 error - we will describe in detail below.

Modern Gorenje models are able to conduct a system self-test and, in case of a problem, to warn the owner. The warning is displayed on the digital display in the form of a cipher - a code by which it is easy to identify the cause of the malfunction. Often, users of automatic devices from Gorenie encounter an E3 error, which indicates problems with the collection of water. The reason may be a banal shutdown of water, as well as a serious malfunction of the module. What exactly broke and how to fix the E3 error - we will describe in detail below.

Reasons for the appearance of this code

A flashing E3 error indicates that there is not enough water in the washing machine to execute the selected program. First, the machine tries to make up for the shortage for a long time, and then stops the system. A number of malfunctions of the Gorenje washing machine lead to this situation.

- Problems with water intake. Low pressure in the water supply, shut-off tap, clogged inlet hose, strainer or water inlet. This also includes other obstacles to the flow of fluid into the drum - kink, squeezing the hoses or disconnecting them from the supply pipe.

- Problems with the drain system. If it is improperly connected to the drain, then all the water entering the machine will immediately drain into the sewer, and the level required to start washing will not be reached. In this case, the set takes a long time and with the characteristic sound of a merging liquid. The amount of water left can exceed a mark of several hundred liters, and if a water meter is not installed in the apartment, it will not be easy to notice the problem.

- Leakage. Everything is clear here - as soon as the system detects a leak, the cycle ends. It is easiest to determine if you pay attention to the floor near the washer.

- Defective pressure switch. This is a water level sensor, and when it does not work correctly, data on the amount of water does not go to the control module. The machine does not know how much liquid is in the tank and whether it is enough to start the cycle, so it does not give a signal to start the wash.

- Control board failure. The situation is the opposite of the previous one. The module cannot receive information about the amount of water, so it blocks the set to prevent leaks and short circuits.

Most of these breakdowns can make themselves known at any stage of washing, but more often the E3 error appears at the very beginning. There is also a characteristic sign of the impending disaster - a long accumulation of water, which is why the machine erases longer than usual time. To accurately diagnose the source of the problem, you will need to check each possible cause one at a time.

There is no water or it does not pass

Despite the impressive list of possible malfunctions, you should not panic and call the wizard. Almost everything can be fixed with your own hands in a few minutes. To begin with, we check the presence of water in the water supply system - often there is a shutdown without warning residents. At the second step, we inspect the tee-tap or water outlet to make sure that the water supply to the machine is not difficult.

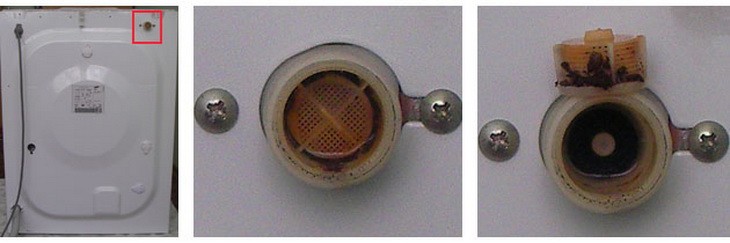

Next, pay attention to the filter mesh, which is located on the inlet valve and is often clogged. Clogs are eliminated as follows:

- turn off the machine from the mains and turn off the water;

- we unscrew the inlet hose and disconnect from the body, loosening the clamps;

Important! Prepare a rag as residual water may spill onto the floor.

- we clamp the filter with pliers or pliers and pull on ourselves;

- we clean the grid with tweezers, and finally we rinse under high pressure of water. If there is a strong scale, it is better to carry out intensive cleaning: soak the product in a solution of warm water and citric acid for 30-60 minutes;

we return the filter and hose to place.

we return the filter and hose to place.

It remains only to check whether the situation has been corrected - we launch express washing on the washing machine. To prevent a new blockage, clean the mesh regularly and install an intermediate filter.. Remember that even in clean tap water there are various impurities deposited on the parts of the machine. If the cleaning did not help, continue the repair and deal with other possible malfunctions.

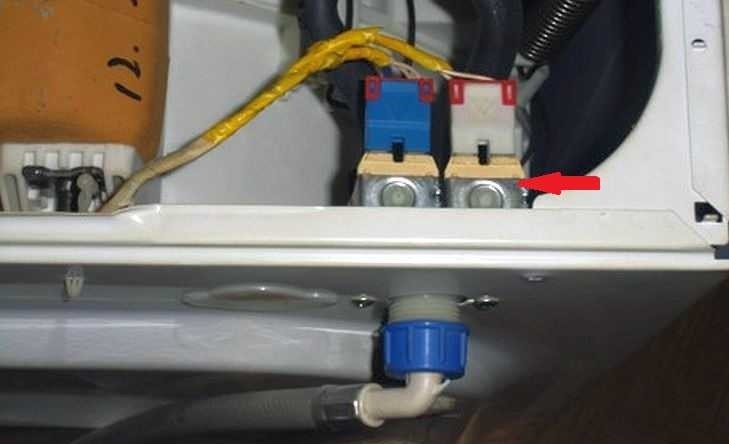

Inlet valve broke

The next in line check is the intake valve, which is also easy to do on your own. We find it under the top panel of the machine at the back wall. It will not work to make a mistake - it is easily determined by the connected inlet hose and nozzles connected to the powder receiver. Next, proceed as follows:

- configure the multimeter to measure Ohms;

- apply probes to each winding;

- evaluate the result, if the displayed value is not close to 3 kOhm - the part is defective.

What to do with a faulty valve? Only change to a new one. We photograph the location of wires and cords, disconnect, then unscrew the retaining bolt and remove the part.

We purchase a similar copy and connect to the typewriter: we fasten the main screw to the wall and, guided by the photograph taken earlier, we connect all the wiring and suitable pipes. We securely fix with clamps and return to place the removed mesh with a cash hose.

Do not forget to check the quality of the set of water by running a quick wash or rinse.

Electronics Issues

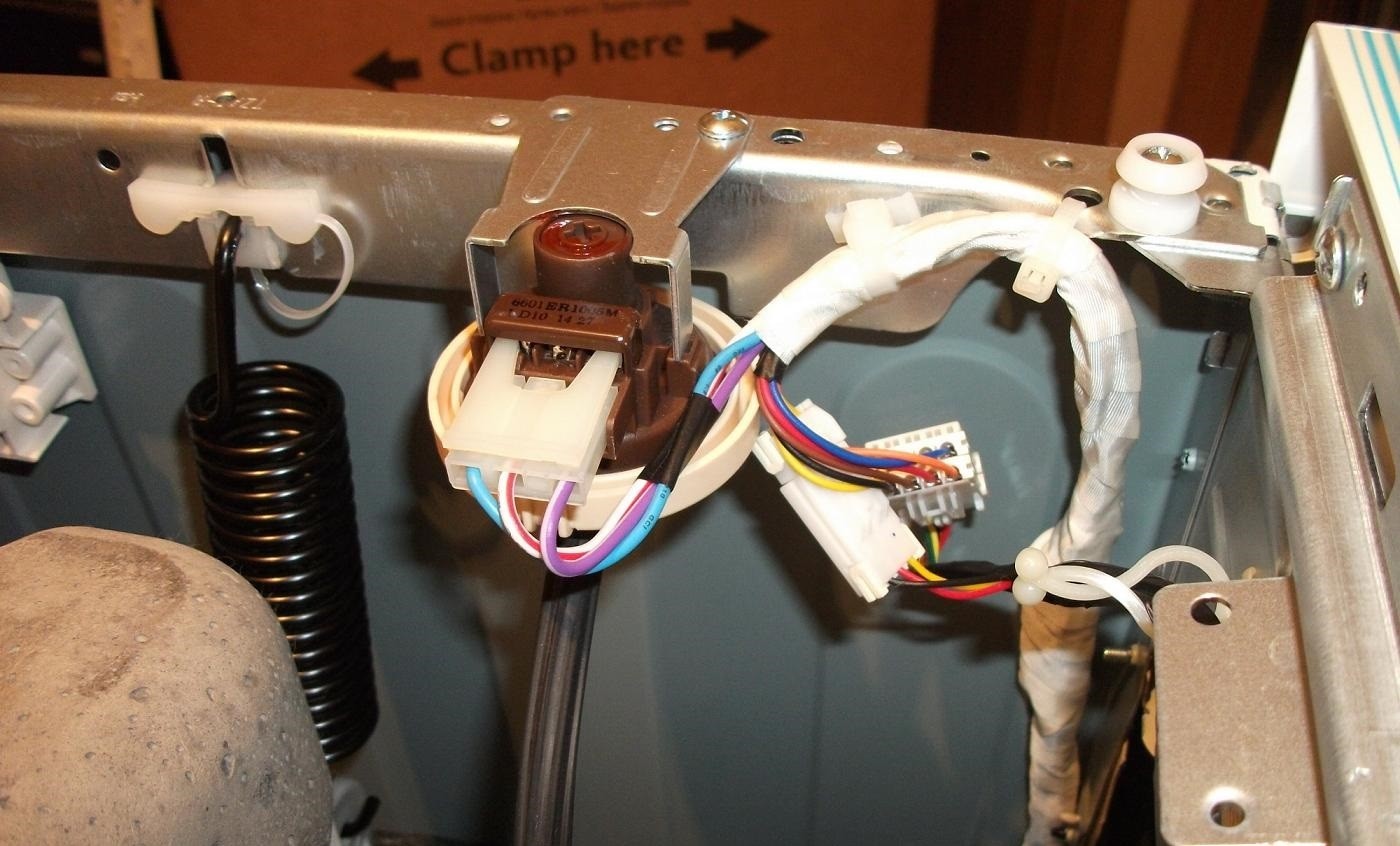

If before this the problem of the E3 error was not detected, then the matter is in electronics. Most likely, the pressure switch is to blame, which incorrectly determines the water level in the tank. We check its performance.

- Remove the top panel.

- We find a small disk to which a long tube is attached, extending deep into the tank. Thanks to this element, the water level in the machine is monitored - when filling, the air pressure changes, and the signal is transmitted to the control board.

- Disconnect the part.

- Blow the tube. We find a tube with a diameter equal to the fitting and insert it into the connector. Blow slightly and listen. The triggered contacts will be felt in a few clicks. Their absence indicates a breakdown.

- We call all the contacts. We turn on the resistance mode and connect the probes to the contacts. Ideally, the values on the multimeter display should fluctuate.

A negative result forces the replacement of the faulty element with a new one. It is not expensive and is very easy to install. It is enough to unscrew the retaining screws and install the working device in a similar way.

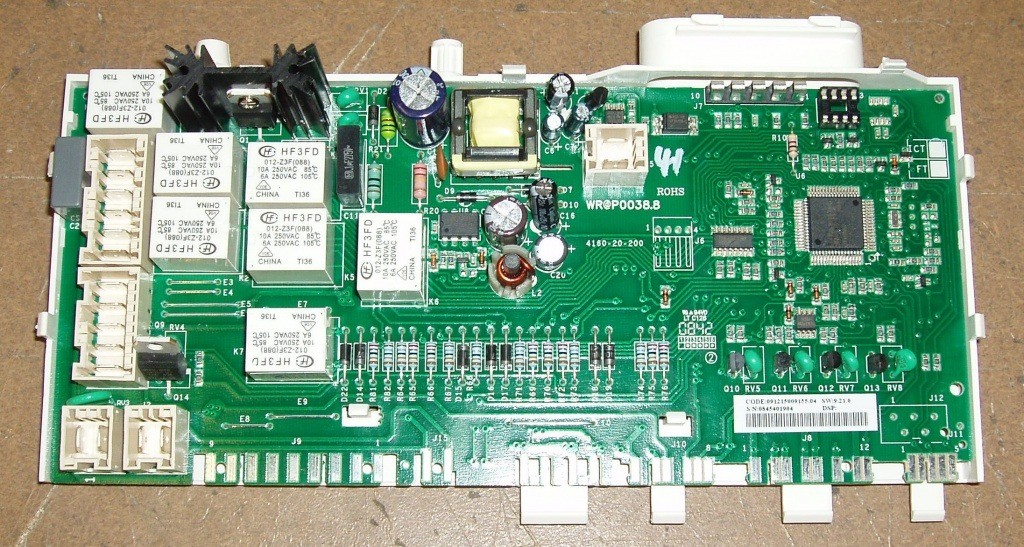

When all the previous elements and sensors have passed the test, then with absolute certainty we can say that the problem is in the control board. It is likely that there was a failure on a separate triac, due to which the module can not get information about the water level and start the washing program. Trying to fix the "electronic brain" of the washing machine on your own is strictly prohibited - even the slightest mistake will aggravate the situation and will cost several times more.

The best option is to immediately contact the after-sales service. Specialists will conduct a comprehensive study, starting with a visual inspection, ringing all the contacts and ending with the reprogramming of the board.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment