How to remove the bearing from the drum

The rattle that appeared while the washing machine was operating at full speed, water leaking at the bottom of the machine may indicate the need to replace bearings. It will be difficult for a beginner to remove this important detail in a washing machine, as it will require some skill. To begin with, it is worth theoretically studying this process, and only then putting everything into practice, evaluating your capabilities.

The rattle that appeared while the washing machine was operating at full speed, water leaking at the bottom of the machine may indicate the need to replace bearings. It will be difficult for a beginner to remove this important detail in a washing machine, as it will require some skill. To begin with, it is worth theoretically studying this process, and only then putting everything into practice, evaluating your capabilities.

Cooking tools for work

To remove the bearing from the drum of the washing machine, special special tools are not required, except for the puller, gently picking up the bearing race and removing it from the shaft. In general, it is enough to have a set of simple tools that most men have on the farm. Depending on the specific model and make of the machine, you may need:

- screwdrivers;

- pliers;

- wrenches (17 and 19 mm)

- key-heads from 7 to 13 mm in size;

- rubber hammer;

- 6 mm hexagon;

- sealant and grease (for example, Silicon-Fett grease or Litol-24 grease);

- chisel;

- puller.

Do not rush to purchase a puller, make sure that the bearing does not require replacement, otherwise it is not scary if you damage its cage with a hammer. If you can not do without a puller, get a universal puller that fits different sizes of bearings, it will come in handy for you in the future.

We take out the tank from the car: instruction

Work on the installation of the tank and the drum begins with the blackout of the machine, also do not forget to close the tap to supply water to the machine. To pull out the drum you need to disassemble the washing machine body. To do this, you need:

- Park the machine so that there is free access to it from all sides.

- Remove the top cover of the machine by unscrewing two Phillips head bolts from the rear for this purpose.

- Pull out the powder tray and conditioner.

- Unscrew the bolt located under the tray.

- Remove the lower front of the machine body.

- Remove two more bolts located underneath.

- Remove the clamp from the hatch and remove the rubber cuff from the body.

- While depressing the locking sunroof device, disconnect the front of the housing.

- Now unscrew the back of the machine body

- Remove the belt.

- We find and disconnect the wires from the heating element.

Important! By disconnecting the wiring and other elements, fix their correct location on the camera, this will facilitate the assembly of equipment.

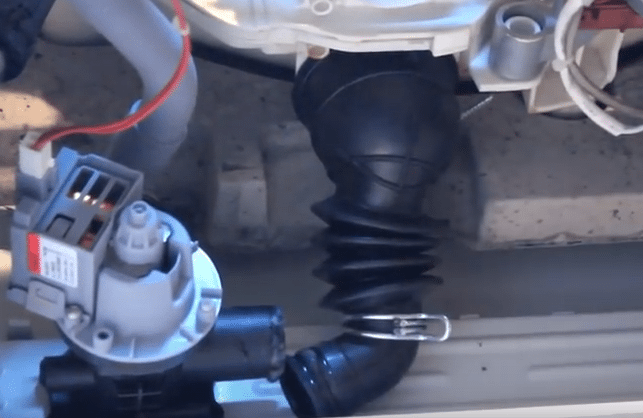

- Disconnect the pipe from the pump to the tank.

- Remove counterweights.

- Unscrew the two bolts holding the engine, remove it.

- Remove the shock absorbers and tank holding springs.

- Now you can get the tank.

Note! For more effective unscrewing of the rusted bolts, a grease is used, for example, WD-40 grease.

Getting a tank out of the car is not so simple, we tried to list the main steps in this matter. For more details on the extraction of the tank and drum, see How to disassemble a tank.

Remove the bearing

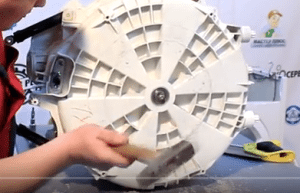

Having pulled the tank with the drum out, we proceed to its analysis and the direct removal of the bearings. If grease has leaked onto the drum cover, this confirms the need to replace oil seals and bearings. So, the tank consists of two interconnected parts. The connection can be glued or with bolts. The adhesive joint must be carefully sawed. Easier in this regard, bolting. When the tank will be disassembled into two parts, perform the following steps:

- We unscrew the pulley of the drum with a special key "asterisk" or with a chisel and hammer.

Note! The bolt is loosened quite difficult, so you need to have a high-quality tool and act very carefully so as not to disrupt it.

- With razvatelnym movements, remove the pulley from the drum screw, and under it is the bearing.

- We knock out the drum shaft inward, thereby separating the tank and the drum of the washing machine.You can pre-change the shaft to the old one, so that the native shaft is not damaged by hammer blows. There are bearings on the inside and outside of the drum.

- When inserting a metal rod under the bearing race, it is necessary to knock it out with a hammer in a circle. You can use a special puller for bearings.

The bearing puller allows you to remove it quickly enough, while not damaging its cage. This may be required in cases where the bearing is intact and the shaft on which it sits is damaged. The shape of the puller can be different, especially since there are a huge number of them on sale. To remove the bearing from the drum of the machine, you need a puller, the paws of which have a shape that, when pulling the bearing, would exert a load only on the inner race of the bearing, the load on the outer race should be minimal.

Usually they remove first a small bearing, then a large one. The seals are removed before the bearings; it is reasonable to exchange them with them. That's all, the bearings are removed, now you can install new components and assemble the machine in the reverse order. When installing new oil seals and bearings, be sure to lubricate them to prevent water from entering. In addition, lubrication will reduce friction between machine parts, which will extend its service life.

Note! When purchasing a new bearing, look at its exact marking, which is applied to the inner race. So you buy a bearing similar to the old.

Is it worth it to change bearings?

When the first signs of bearing failure appear, you should immediately think about repairing the machine. Its further operation can lead to more serious breakdowns, for example, deformation of the cross, the replacement of which will cost much more. If the failure of the bearings leads to water leakage, the heating element may burn out and the electronics system in this case will have to say goodbye to the machine forever.

When the bearing breaks, you should not immediately panic and think about the big expenses for new equipment. Even a repair in a service center will cost no more than 2000 rubles, and if you do it yourself, it’s several times cheaper. A similar detail, along with seals on the washing machine breaks quite often. Some experts say that they need to be replaced every 5 years or at least lubricated.

So, if the removal process was not entirely clear, watch the video on how to replace the bearing in the washing machine.

Interesting:

How to disassemble a Zanussi washing machine

How to disassemble a Zanussi washing machine How to change the bearing in an Ariston washing machine

How to change the bearing in an Ariston washing machine Replacing the bearing in a Zanussi washing machine

Replacing the bearing in a Zanussi washing machine How and what to lubricate the bearing in the washing machine

How and what to lubricate the bearing in the washing machine How to change the bearing on a Samsung washing machine

How to change the bearing on a Samsung washing machine How to change the bearing in the LG washing machine

How to change the bearing in the LG washing machine

1 reader comment

Add a comment Cancel reply

Headings

Washing machine repair

For buyers

For users

Dishwasher

Super! All clear. Now you can change.