Circular from the engine from the washing machine

Such a useful thing as a working engine from an automatic washing machine should not be idle in your garage.

Such a useful thing as a working engine from an automatic washing machine should not be idle in your garage.

Any self-respecting self-respecting hands will comb their hands at the sight of such a promising detail.

In this article, we will tell you how to make a very good light and compact circular tool on the basis of such an engine, on which you can easily dissolve the fiftieth board or even a 10x10 block.

Attention! Assembling a circular saw with your own hands and its further use can be dangerous! Therefore, do not tackle this matter if you are not confident in your skills and do not follow safety rules! This article is not a call to action. And remember, all responsibility for what you do lies only with you!

How to connect a motor?

Connecting the engine is the most important stage of work, if you can’t connect the engine from the washing machine correctly, then you won’t be able to do the circular yourself. The whole difficulty is not even in connecting, but in achieving stable adjustment of the engine speed, without this the circular will not work normally - the disk will tear the lumber.

Connecting the engine is the most important stage of work, if you can’t connect the engine from the washing machine correctly, then you won’t be able to do the circular yourself. The whole difficulty is not even in connecting, but in achieving stable adjustment of the engine speed, without this the circular will not work normally - the disk will tear the lumber.

The manufacturer installs a so-called tachometer or speed sensor on the engine from the washing machine. But the problem is that the electronic module of the washing machine controls the operation of this sensor, you can’t put such a module on the circular, so you will have to think about a device that will control the engine speed. Detail on howadjust engine speed from the washing machine described in the same article.

Moving parts

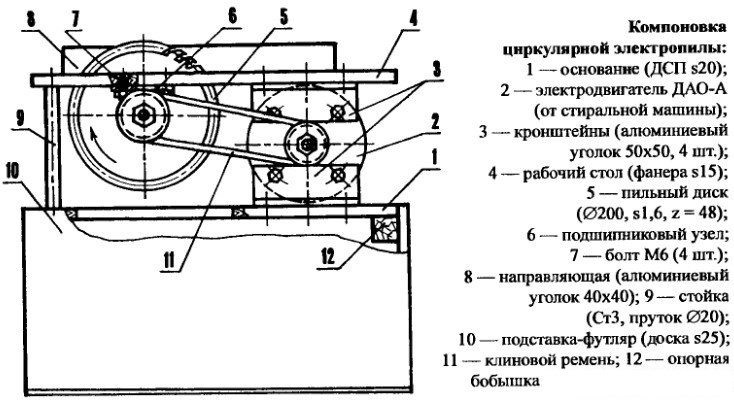

Having successfully connected the engine from an automatic washing machine with your own hands, and having checked how it gains and slows down, you can start making our circular. The diagram below shows a simplified drawing of a home-made circular saw made using the engine from a washing machine.

The scheme can be further simplified by being from the bearing assembly. For household circulars, this is quite acceptable.

So far, we will only be interested in the moving elements of the circular, which will bear the main load, namely:

- circular saw shaft;

- washing machine motor shaft;

- drive belt;

- a pulley of a washing machine motor;

- pulley of a shaft of a circular saw.

The drive mechanism should work as follows. The motor from the washing machine drives the shaft with a small pulley pressed onto it. A drive belt is dressed on a small pulley, which transfers revolutions to a large pulley, dressed on a shaft, which drives a circular saw. Everything seems simple at first glance, but when you make a circular, a lot of subtle difficulties come up that have to be solved.

- The small pulley must be drilled with your own hands, making 3-4 transverse grooves on it, so that the belt clings to them and does not slip.

- The drive belt does not have to be taken from the washing machine, you can take a similar part from any other equipment, if only the belt was durable and had serrated.

- On a large pulley, you will have to weld a slightly larger diameter disc with your own hands to form a kind of protrusion that will prevent the drive belt from slipping off during operation. On a large pulley, it is not necessary to grind serrations; traction with a belt will be normal without it.

- The shaft on which the circular saw will be held, as well as the nut and washer, must be reliable so that, firstly, the saw does not deform at high speeds, and secondly, that the circular saw does not pop out and cause harm to the person working with the circular . It is better to take the finished shaft, washers and nut from the factory factory circular.

The described mechanism is designed for a three hundredth disk. There are many skeptics who say that the drive from the washing machine will not pull such a disk, and that it will stop at some point during operation, and the saw will be stuck in the board. To our skeptics, our experts answer the following.

- First, you need to be able to work with the circular tool and not push anything on the rotary saw.

- Secondly, this circular will be purely household, it is designed for short-term work with a small amount of lumber. If you want to make a circular for business, then purchase special components, such equipment is not manufactured from improvised parts.

- Thirdly, practice shows that quite a lot of craftsmen use such home-made equipment and are very satisfied. At least the feedback from them is mostly positive.

In the future, do not overload your homemade circular with work, and most importantly, do not let the engine run for a long time without load.

Bed and frame

Having assembled the parts for the moving parts of the circular we only need to make a reliable frame and bed for our circular. In principle, for the bed of household circulars, you can take the most ordinary improvised material, for example, a piece of thick flat slate. Cut a rectangle out of it and cut a hole for a circular saw does not cost anything. But we are supporters of capital constructions, therefore we prefer to take circular sheets for a bed of metal 3 mm thick, and for a frame 30 mm a metal corner.

In the figure above, it is clearly seen what elements the frame of a homemade circular consists of. In this case, it is also welded with your own hands, only not a static metal corner, but special home-made racks are used as supports. The stand is made of two metal pipes of different diameters, which are inserted into each other, so that the circular bed can be adjusted in height.

Experts insist on the welded construction of the circular frame, since vibration does not adversely affect the static fastenings created with bolts. Although if you do not have welding, in extreme cases, you can make a frame of corners by fastening them together with bolts and nuts. It is also better to weld the frame to the frame.

So, it’s quite possible to make a circular from the engine of the washing machine with your own hands, if you have experience in manufacturing various homemade products. Try it yourself and, perhaps, you will accumulate some experience, which you later share with our readers. Good luck

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment