What is a pressure switch in a washing machine?

A level sensor or pressure switch is a small-sized device that monitors the volume of water poured into the tank. Without it, the system of the washing machine will not start the fence, will not receive a signal to start the wash, and will not turn on rinsing or draining. In order not to be in an unpleasant situation in front of an idle machine, it is better to deal with a miniature, but important device in advance. We will discuss this article in detail about its appearance, internal structure, principle of operation, probable breakdowns and verification methods.

A level sensor or pressure switch is a small-sized device that monitors the volume of water poured into the tank. Without it, the system of the washing machine will not start the fence, will not receive a signal to start the wash, and will not turn on rinsing or draining. In order not to be in an unpleasant situation in front of an idle machine, it is better to deal with a miniature, but important device in advance. We will discuss this article in detail about its appearance, internal structure, principle of operation, probable breakdowns and verification methods.

What does the sensor look like?

Finding a pressure switch is easy: just unscrew the top panel of the washing machine and look around. You need to find a small plastic element with a round lid - this is what this part looks like. Several conductors from the control board and one long tube falling down come up to it. A special pressure vessel is also connected. The principle of operation of the sensor can be described as follows.

- The liquid that accumulates in the washing machine provokes pressure in the pressure tube.

- As soon as the equation of water and pressure occurs, the switch closes and the contacts open.

- The control triac receives a signal about a sufficient fence.

If a failure occurs in the pressure switch, the system is not informed about the amount of water flooded. The result is underfilling or overflow. Due to the lack of information about the degree of fullness of the tank, the machine is often insured and activates the pump to remove excess in order to avoid leakage. Not having time to get into the tank, all the liquid from the water supply immediately drains into the sewer.

This continues until the owner of the washing machine stops the fluid intake and removes the cause of the problem.

Sensor device

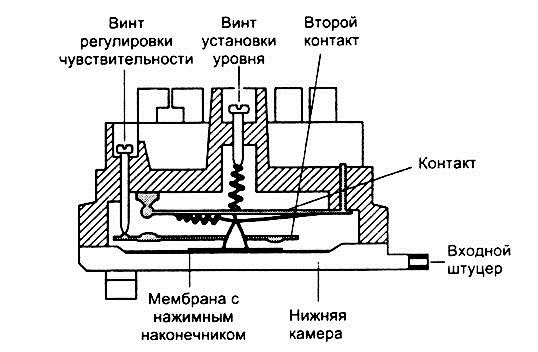

Now we will understand how the pressure switch is arranged. The main part of the sensor is a plastic case that holds the main structural elements. Among them:

- inlet fitting;

- membrane with pressure tip;

- two parallel contacts;

- sensitivity adjustment screw;

- level setting screw;

- persistent elements fixing two springs.

Variations are not excluded. So, in electronic pressure switches there is an oscillatory circuit. In two-chamber - in addition to the lower hollow compartment, a second one is provided from above, as well as an additional intermediate membrane and a pair of contacts.

Typical level sensor failures

Knowing what a level sensor is and what it is responsible for, it is easier to suspect something was wrong at the earliest stages. Then you can fix the problem quickly and at minimal cost. So, you can guess about the failure for several symptoms.

- The cycle started with an empty drum. The system did not receive a signal about an empty tank and started washing. Worse if the heating element is turned on at the same time. This will inevitably lead to burnout of the heating element and failed wiring, not intended for idle operation.

- Water withdrawal does not stop or stops immediately. The first option is worse, since uncontrolled filling of the tank is fraught with leaks and a short circuit.

- Drain difficult. Signaling the need for draining is another point for which a pressure switch is needed. If a failure occurs, then after the spin cycle is completed, the cycle stops with a full tank and a locked hatch door.

- No rinsing. Water cannot be replaced by clean water, since neither the drain nor the bay works.

Modern washing machines are able to diagnose the problem on their own and display a corresponding error on the digital display. In older models, the situation is more complicated - the sensor must be constantly checked for operability in order to fix a malfunction in a timely manner. The verification algorithm is described below.

How to check the item?

Before blaming the water level sensor for the stalled operation of the washer, you must confirm or refute your guess. To do this, it is enough to test it for performance by a simple algorithm. We act like this:

- disconnect the washing machine from the mains;

- we block water;

- remove the top panel from the machine, unscrewing the two screws on the back and sliding the cover towards you;

- determine the location of the sensor (most often it is located in the upper part of the side wall);

- we find a tube with a diameter equal to the inlet fitting;

- weaken the clamp on the pressure hose and unhook it;

- we insert the prepared tube into it and easily blow.

If you heard 1-3 clicks, then the contacts work smoothly. Next, carefully inspect the housing and all adjacent wires for damage and blockages. The final stage of testing will be the connection of the multimeter. We configure the device to measure resistance and apply probes to the terminals on the pressure switch. Everything is in order, if the values on the display change, otherwise - we dismantle the part and install a new one.

Important! In some cases, you can adjust the pressure switch by tightening the screws, but only service technicians do this.

Most often, a damaged sensor cannot be repaired. It remains only to unscrew the screws holding the case, cut the clamps and disconnect all pipes with contacts. After you purchase a similar copy and install it in the washing machine in place of the previous one.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment