Ariston washing machine does not wring

Ariston washing machines are famous for their excellent spin - their owners very often note this particular feature among the advantages of this brand of washing equipment. However, sometimes they encounter a problem - Ariston's washing machine does not wring. Often, the drum even rotates, but not so fast as to create the desired effect and to squeeze out the washed clothes. What is this happening for? How to avoid this problem and solve it in case of occurrence?

Ariston washing machines are famous for their excellent spin - their owners very often note this particular feature among the advantages of this brand of washing equipment. However, sometimes they encounter a problem - Ariston's washing machine does not wring. Often, the drum even rotates, but not so fast as to create the desired effect and to squeeze out the washed clothes. What is this happening for? How to avoid this problem and solve it in case of occurrence?

When it’s not a breakdown

If the machine does not wring out, this is not always a signal of damage. No need to be scared right away and start planning large repairs costs. Among the main causes of poor spin (or lack of spin) are squeezing or twisting of the drain hose. At the same time, water cannot drain into the sewer. You just need to check the hose and the outlet pipes.

Some washing modes do not imply spin. For example, if you select a delicate wash or a wash of wool, the spin mode will not be activated. If necessary, wring things, you need to enable the spin mode manually.

The laundry will remain wet if the spin program is selected at low speeds. In this case, the spin will be performed, but the laundry will be wrung out unsatisfactorily. It is necessary to start separately the spin mode at higher speeds.

If the machine is not loaded with linen optimally, it will not wring well. Almost all modern models have the function of intelligent weighing. If the machine, after weighing the linen, considers that its weight is not optimal for the spinning operation, it will not start this mode. Weight can be either too large or too small. Remove excess items from the drum or vice versa, report more items so that the optimal weight for the spin is set.

If, after checking all the above reasons, the machine does not squeeze out the laundry, it may be a breakdown. It will take a little repair. Let's analyze the main points.

The fault is to blame

A tricky malfunction may be to blame for this problem. What to do, where to look for reasons? The most frequent breakdowns leading to a violation of the spin function of the laundry are:

- problems with the drain pump;

- breakdown of the pressure switch;

- incorrect operation of the tacho sensor;

- engine malfunctions;

- error in the control module.

Here are the main common causes of spin failure. There are others, but mostly experts indicate that their frequency is negligible. First you need to carry out repairs with your own hands to inspect each specified element.

Check and repair the pump

Everything is much simpler if the code F11 lights up on the display of the washer. This just indicates a problem with the drain pump. First, find the appropriate node. You need to put the car on the side surface. Before that, lay a soft cloth on the floor - this will save the case. Having unscrewed the screws, you need to remove the bottom (if it is installed on your model). Further we act as follows.

Everything is much simpler if the code F11 lights up on the display of the washer. This just indicates a problem with the drain pump. First, find the appropriate node. You need to put the car on the side surface. Before that, lay a soft cloth on the floor - this will save the case. Having unscrewed the screws, you need to remove the bottom (if it is installed on your model). Further we act as follows.

- Carefully feel the drain pipe. If blockages are felt in it, it must be removed from the pump.

- Loosen the retaining part of the clamp.

- Having unscrewed the bolts that hold the part, you need to disconnect the electrical wires.

- Take out the pump.

- Disconnect the pipe from the tank, rinse it under running water. Thus, it cleans well.

Visually inspect the pump. Often the pump is simply clogged with dirt, because of this it does not work. Rinse it. After that, put in a regular place and ring with a multimeter. If there is no signal, pump replacement is required. The same goes for impeller failure.

Check and replace level sensor

The described spin problems may also occur in the event of malfunctions from other units. Before replacing the pressure switch, you must finally make sure that the old one does not work. To check it, you need to remove it.To remove the pressure switch (it is also a water level sensor), you need to perform a number of simple steps.

- Remove the top cover of the machine by sliding it back. The pressure switch is located on the side wall. It is fixed with special screws.

- It is necessary to disconnect the wires and remove the hose from the pressure switch. Release screws securing unit and remove.

- Inspect the part, rinse it with water if contamination is suspected. Connectors must not be oxidized. If there is oxidation, they must be carefully cleaned.

- Check unit operation.

Next, put the hose on the fitting, bring it to the ear and blow it into the free end of the hose. A specific click should be audible in the unit. This indicates that there is contact. There can be several clicks, it depends on the model.

Lack of clicks is the worst sign. It indicates that the part is defective. If there are clicks, it is necessary to check the reliability of the operation of the contacts with an ohmmeter. It is necessary to connect the measuring device to the corresponding sockets at the input of the unit. When closing and opening, a surge will be observed. If it is not there, then the node is faulty. If the results of these steps make it clear that the pressure switch is not working, it must be replaced.

It is worth checking the Hall sensor

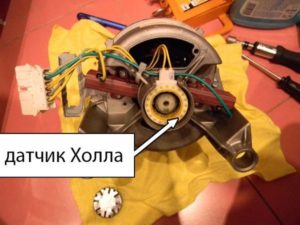

If everything is normal with the pressostat, we’ll go closer to the engine. But before checking the engine, it is still important to make sure that the tachometer is working. Often, it can also cause a problem. To check the specified part, the washing machine will have to be disassembled. The sequence of actions is as follows:

- disconnect the equipment from the power supply, as well as from communication outputs and inputs;

- on the back wall of the case you need to remove all the screws, remove the wall itself;

- remove the drive belt by pulling it slightly towards you and simultaneously rotating the pulley.

Now you need to remove the engine from the machine. It is first important not to forget to mark all the wires that lead to the engine. Next, remove the bolts that hold the motor. Gently rocking the motor, take it out of the car. After removing the engine, you can well consider the Hall sensor. Among the probable reasons for its malfunctioning: loosening of the mounts, disconnecting the contacts. All this can be associated with strong vibrations. It is necessary to tighten the bolt and check the contacts. The resistance on the tachogenerator is checked by the following method:

Now you need to remove the engine from the machine. It is first important not to forget to mark all the wires that lead to the engine. Next, remove the bolts that hold the motor. Gently rocking the motor, take it out of the car. After removing the engine, you can well consider the Hall sensor. Among the probable reasons for its malfunctioning: loosening of the mounts, disconnecting the contacts. All this can be associated with strong vibrations. It is necessary to tighten the bolt and check the contacts. The resistance on the tachogenerator is checked by the following method:

- we put the tester in the resistance measurement mode;

- you need to unclench the connectors of the wires and move them away from the sensor contacts;

- check the resistance by connecting the probes to the contacts.

The resistance rate for the tachogenerator is 60-70 Ohms.

We turn on the tester in the voltage reading mode, you need to find out if the current is generated. If so, then the problem is not the tachogenerator. We apply the tester probes to the sensor contacts. Scrolling the motor with a hand we monitor the readings. If the readings change, current is generated. Normally, the device should show a voltage in the region of 0.2 Volts. And in the end, you must definitely check all the wiring. The tachogenerator itself breaks extremely rarely. If you find a problem with the Hall sensor, you will need to replace it.

Open the engine

Since collector motors are installed on Ariston washing machines, engine malfunctions often occur. In such a motor can break: brushes; lamellas; rotor winding; stator winding.

The brushes are located on the sides of the motor housing. There are two of them. They are made of fairly soft metal, hence their tendency to wear out quickly. Replace them if you see mechanical wear. Usually it is visible "by eye". If wear is not visible "by eye", it is recommended to turn on the engine and observe its operation. If the brushes spark, it means that they need to be replaced.

New brushes can be bought at any store where there are parts for Ariston washing machines.

Problems with lamellas arise due to the peculiarities of their fastening: they are attached to the shaft with glue.For this reason, they can often peel off in the event of a motor jam. If the damage is small, you can grind the collectors on a lathe, and the problem will be solved. Metal chips should be cleaned with a sandpaper.

The lamels must be carefully inspected visually. It is especially necessary to pay attention to the presence of delamination. Any burrs can cause a malfunction of the malfunction of the “heart” of the washing machine.

If there is a problem directly in the winding, this will manifest itself in a decrease in engine power up to a complete stop. After a short circuit, an emergency shutdown of the engine occurs. The performance of the windings is checked with a multimeter. It must be included in the resistance mode. Next, attach the probes to the lamella. The normal indicator should be in the range of 20 - 200 ohms. A lower value indicates a short circuit; a larger value indicates a break in the winding.

To check the stator operability, you need to put the multimeter in the "buzzer" mode. The probes must be applied individually to the ends of the wiring. The absence of sounds will indicate the absence of problems. If the device makes a sound, then there is a problem.

Next, attach one probe to the wiring, and the second to the body. There should be no sounds. Their presence will indicate a problem. If a malfunction is detected in the winding, it will not be possible to repair it yourself. Will have to completely replace the entire engine.

Maybe it's in the electronic board

If the error code F18 is displayed, this indicates the need for a flashing of the electronic board. Such repairs cannot be performed independently. You must have specialized knowledge in the field of electronics and programming technology. It is necessary to know the features of specific models of washers.

If such a failure is detected, it is best to contact the customer support center immediately.

Repair of the Ariston washing machine is not as complicated as it might seem at first glance. As we can see, it is not difficult to understand the causes of poor spin or lack thereof. And only in the most difficult cases concerning the “brains” of the washing machine, one really has to turn to specialists. In other situations, it is possible to fix the problem yourself, spending a minimum of time on it.

Interesting:

Reader Comments

- Share your opinion - leave a comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment