Dowel connections are very popular among carpenters; this is the only way to make the places where parts are fixed completely invisible. But there is one problem - it is quite difficult to accurately center the holes for the dowels. Professionals make various devices to facilitate the process, we bring to your attention one of them.

What is required to make a conductor

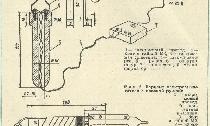

The parts are made from small pieces of wood or plywood, the holes are centered with pieces of aluminum tube with a diameter of 8 mm, and the hinges are made from self-tapping screws. The pendulum centering mechanism is made of aluminum strips 2 mm thick, 20 mm wide and 100 mm long. The range of materials may vary depending on availability.

Manufacturing process

Make a plank from a small oak log; first pass it through a surface planer and a circular saw. The width of the strip is 18 mm.

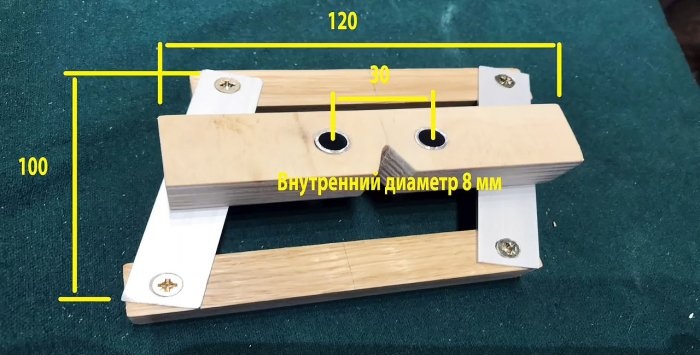

Make the base of the device from 12 mm thick and 3 cm wide plywood. Place a fence on the circular saw table and prepare the parts.You will need one piece of plywood 120×40×20 mm, marking tubes and two oak strips 120×18×18 mm for the side clamping elements are installed in it.

If the central part is too wide, it can be narrowed using a circular saw. In our case, the width is reduced to 26 mm.

Cut two pieces of aluminum tube. The inner diameter is 8 mm to match the size of the dowels, the outer diameter is 10 mm. The length of the pieces is 20 mm and corresponds to the thickness of the central plywood part. You can cut the tube using a homemade jigsaw or a hacksaw.

Cut two pieces of aluminum strip measuring 100x20x2 mm.

In the middle of the central part, cut out a sight in the shape of a triangle. With its help, the position of the device is controlled. If it’s a little off, no problem, correct it manually and move the line of symmetry (base) in one direction or another.

Mark the holes for the tubes and place them exactly in the middle of the part. We have a distance between the dowels of 30 mm, respectively, from the sight each hole is at a distance of 15 mm. Use a caliper and a square.

In the main part, drill two holes with a diameter of 10 mm for the tubes, press them in a vice. The tubes fit tightly; no additional fixation is required.

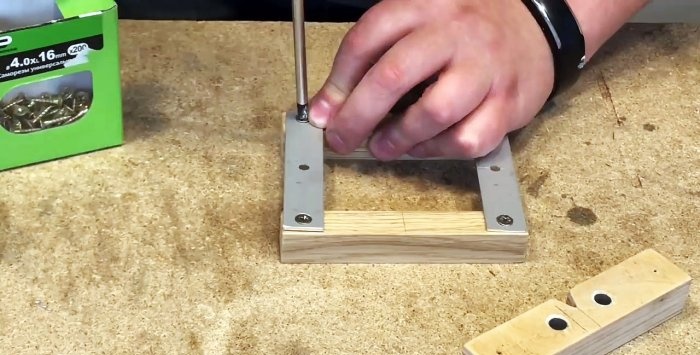

Using a drill with a diameter of 4 mm, drill three holes in the aluminum plates. One in the center and two on the sides at a distance of 5 mm from the end.

Countersink the holes with an 8mm drill bit. The central hole must be countersunk on one side, and the side holes on the opposite side. This is due to the fact that the screws are screwed in from different sides.

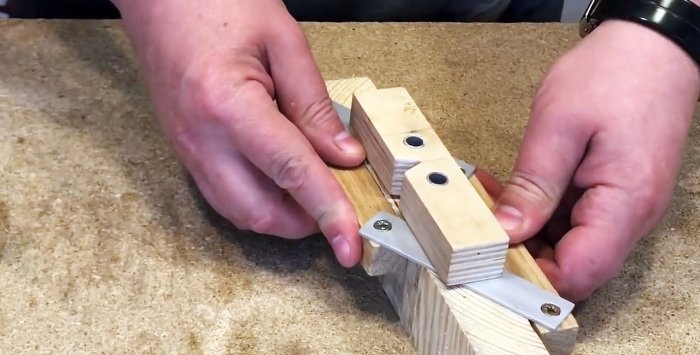

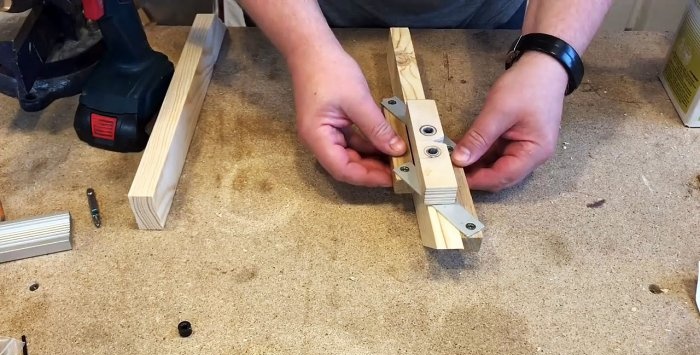

Place the workpieces on a flat surface and assemble all the parts using self-tapping screws. Do not tighten the hardware completely; the planks should move freely, but not wobble.

First, assemble the sides, and then screw them to the main central part. Check the movement of the device.

How to use the device

Place the two parts you want to connect on the table. Mark the places of symmetry for two dowels for each connection (we will have four in total).

Transfer the markings to the side plane of the parts using a square.

Install the device on the board. Align the sight with the markings, and use clamps to secure the position of the jig.

Drill holes using aluminum tubes as guides. If the jig is made correctly, the dowels will fit perfectly.

Place the workpieces on a flat surface and mark the location of the dowel.

Add 15 mm from the marking, this line is needed to align the sight, transfer it to the end of the parts.

Put on the jig, align it with the sight and marks, drill holes for the dowel. Drill two pieces.

Insert a dowel into the hole and connect them. Everything must match exactly.

Conclusion

The device is installed exactly in the center of the workpiece only if all dimensions are maintained as accurately as possible. Such devices can be made for different numbers of dowels.