A little theory...

After hardening and subsequent low-temperature tempering, the hardness of the bearing steel must be at least HRC 62. Moreover, it contains approximately 1% carbon and 1.5% chromium, which ensures the quality of hardening of bearing steels throughout the entire volume of the product.

This metal is hardened at a temperature of 830°C in oil, followed by tempering for at least two hours at a temperature of 160 degrees Celsius.

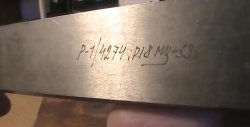

It is clear that not every tool will be able to process bearing steel with the above characteristics. For example, the hardness of tool steels grades P6M5K5, P9, P9M4K8, P18 is no more than HRC 59, and grades U7, U8, U10, U12, P6, depending on the tempering mode after hardening, ranges from HRC 59 to HRC 63.

Cutters testing

Considering that some tool steels, having lower or comparable hardness, are clearly not suitable for machining bearings, we will try to use two cutters for these purposes: made of T15K6 steel and with an insert made of CBN (other names: borazon, cubonite, kingsongite, cyborite).

In order to more accurately install a standard sharpened cutter in the tool holder, we “face” its base and secure the bearing ring in the machine chuck as accurately as possible along the misalignment.

Let's try to process the ring end at a speed of 315 rpm in several passes with a minimum thickness of chip removal and without the use of cutting fluid (coolant).

Visually, the quality of the processing looks quite good, but the cutter has become dull and requires new sharpening.

For the second time, when sharpening the cutter, we make the main angle negative, apply coolant and reduce the rotation speed of the chuck from 315 to 250 rpm. We also use, as for the first time, the minimum feed.

At first glance, the processing surface looks quite smooth, but the cutter failed again and not only became dull, but the cutting edge of the plate chipped.

Now let's try a cutter with a CBN insert at a speed of 315 rpm without using coolant.

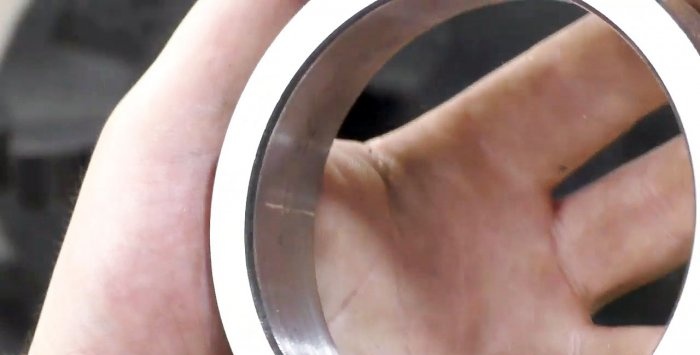

We will process the inner and side surfaces of the bearing ring using several passes.

The surfaces treated with CBN look very high quality, and the insert itself is not damaged at all, although chips and chips are visible here and there on the metal framing it.

After the third regrinding, let's try to use the T15K6 cutter at a low speed of 115 rpm, since the diameter of the bearing ring is still 105 mm.But already at the very beginning of the grooving, the cutter plate was damaged - it chipped and the operation had to be stopped.

conclusions

Unless we came across a defective T15K6 cutter, then it is clearly not suitable for processing bearing steels under any cutting conditions.

Another thing is a cutter with a CBN insert. It ensured the quality of processing and did not suffer at all.