Materials:

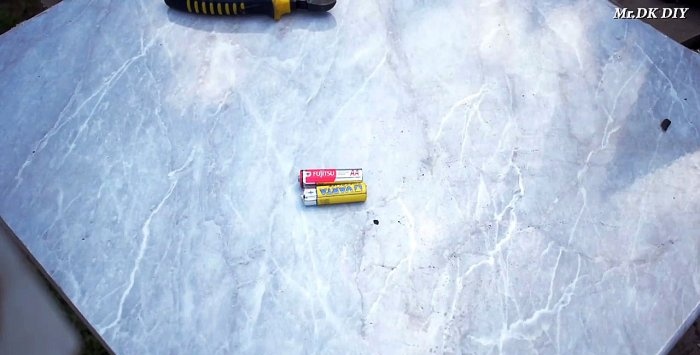

- old spoiled AA batteries;

- 12V battery

- terminal;

- welding or other cable of large cross section.

Welding machine assembly and welding

A graphite rod from a finger battery will be used as an electrode for welding. To do this, it must be carefully disassembled with side cutters. It is better to work with gloves so as not to cut yourself on the battery case. In this case, it is better not to rush, because you can break the rod.

The battery terminals must be connected along the length of the welding cable. On low capacity batteries, it is best to use short wires to reduce resistance. It is optimal to use segments with a length of 40-60 cm. A long cable can be used on 60, 75 Ah batteries.

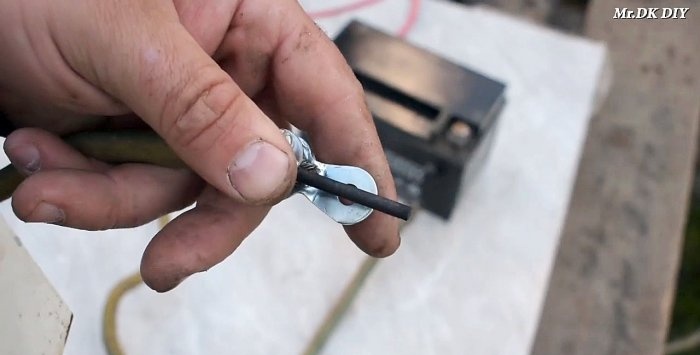

A terminal is placed on the other end of the positive cable. A graphite rod from the battery is attached to it. It must be tightly clamped to get a reliable contact.

The negative wire must be attached to the part for welding. In the absence of a special welding mass, it can simply be crushed. It is necessary to press with pliers or another tool with insulation.

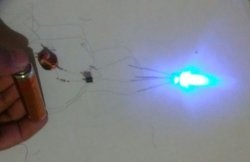

When the graphite rod touches the parts, it will begin to warm up and melt the metal. From this they will be welded together. At first, the lead burns out until the remaining acid from the battery leaves it, and then it cooks better.

This welding method is accompanied by a short circuit on the battery, which causes the battery to heat up. If it boils, it may explode. In this regard, you can not keep the circuit closed for a long time. You need to pause and periodically check the battery temperature. Ideally, cover it so that in case of explosion acid splashes do not get on the body. The probability of this is very small, but reinsurance will not hurt. Welding takes a lot of energy, so one charge is enough for just a couple of minutes.

Instead of a graphite rod, welding electrodes can be used. In this case, you get a really reliable connection that can hold the load. You can also use battery rods in conventional welding, if there are no electrodes at hand.