Materials:

- liquid silicone for molds;

- translucent cold-curing plastic;

- color for plastic;

- technical petroleum jelly;

- toothpicks;

- a thin tube or twig, a Chupa Chups stick will do;

- glue gun with hot glue;

- plexiglass;

- cardboard;

- plasticine;

- large syringe.

Making castings

To cast the bottom of the mold, it is better to use plexiglass. A lantern is placed in its center and outlined with a marker. Around the contour you need to make plasticine pins to join the halves of the future shape. Cardboard can be used to make borders. It is glued with a glue gun. The distance between the walls and the contour should be 1.5-2 cm.

The lantern is placed into the finished mold with the bowl facing up and filled with silicone.

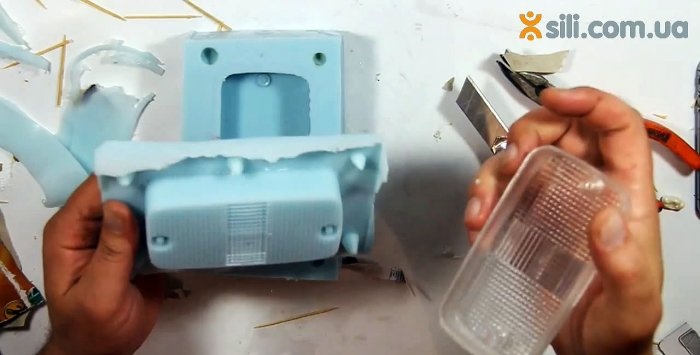

After the composition has hardened, the walls are removed.Plasticine spikes are removed from the resulting casting, and it is also trimmed around the perimeter to remove smudges. Silicone from the lantern bowl goes to waste.

The surface of the cast mold is lubricated with Vaseline. This is done especially carefully in the recesses of plasticine. Using a glue gun, you need to glue toothpicks with the tip removed to the elevations of the lantern. This is necessary to create channels for air bubbles to escape. A thin sprue tube is glued in one place.

The lantern is inserted back into the casting. After this, it is again laid on plexiglass and surrounded by cardboard sides. Their joints are glued with hot glue, and the contents are filled with silicone.

After the composition has hardened, the cardboard is torn off, the toothpicks are removed and the halves are opened. Vaseline prevents them from sticking together. At the same time, the silicone does not stick to the plastic of the flashlight, so it can be easily removed.

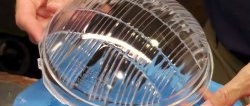

The halves of the form are docked without a lantern. Using a syringe, liquid plastic tinted in the desired color is poured through the casting hole left by the tube. The composition fills all cavities, since air pockets escape through the channels from the toothpicks.

After the plastic hardens, the mold is opened, the resulting product is straightened with a file and used for its intended purpose. The form can be reused. To do this, you must first remove the frozen plastic from its air exhaust channels.

This technology cannot be called cheap, given the cost of silicone and optically transparent resins. But if you need a flashlight for a vintage car that is no longer for sale, then this method is the only solution to the problem.