Materials:

- engine anchor;

- bamboo skewers;

- sandpaper.

Nozzle making

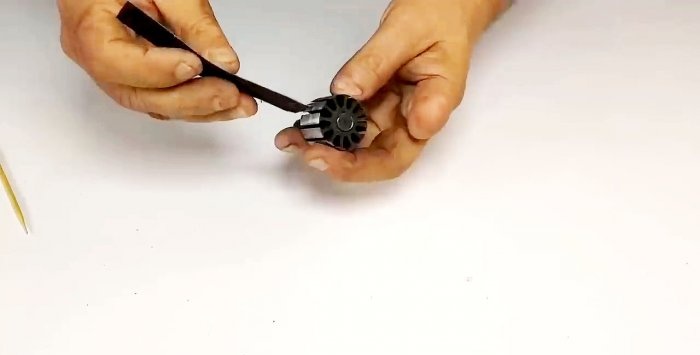

An engine anchor is removed from a broken power tool. It can be removed from the grinder, jigsaw, screwdriver, drill, hammer drill, etc.

The armature shaft on the impeller side is cut as long as possible. In the future, this part will be used to clamp the nozzle in the drill chuck, so it is important that the shank does not work short.

Now the anchor needs to be cut from the side of the contact pad along with the winding along the core line.

The workpiece is clamped in a vice. With the help of a chisel, it is necessary to knock out the protruding part of the winding from the side of the shank.

The winding remaining in the core can only be removed after firing. To do this, the anchor is placed in the fire so that the bonding wire sticks out. The workpiece must be kept on fire until it ceases to burn.

After the impregnation burns out, the cooled anchor is normally cleaned of the wire embedded in the core. Since it is covered with soot from fire, it should be polished.

Grind sandpaper from black.

Mounting options for sandpaper for a cylindrical nozzle

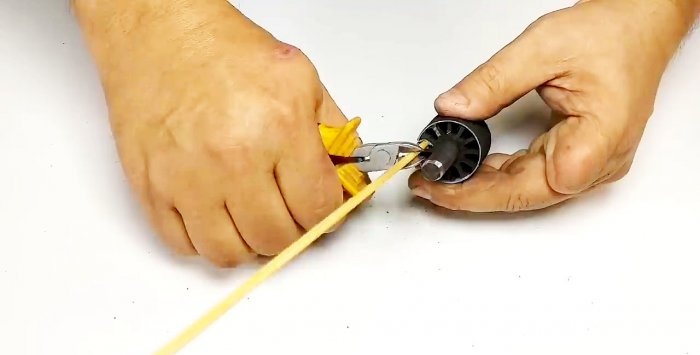

From a sheet of sanding paper you need to cut a strip across the width of the core. Its length should be 1.5-2 cm more than the circumference of the anchor. The strip is wound around the core, while its edges are inserted into one of the segments.

To fix them in a segment, a bamboo skewer is hammered. It turns out a cylindrical grinding nozzle.

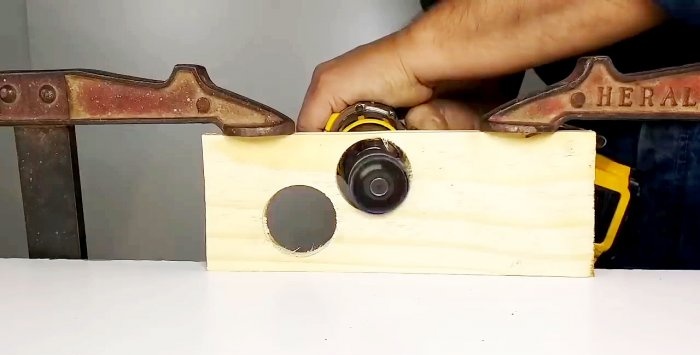

The charm of this nozzle is the ease of replacing paper, since you do not need to glue anything. Such equipment can be used for grinding round holes and other complex surfaces.

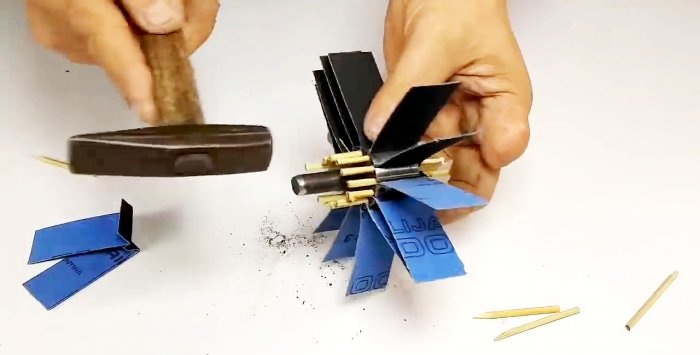

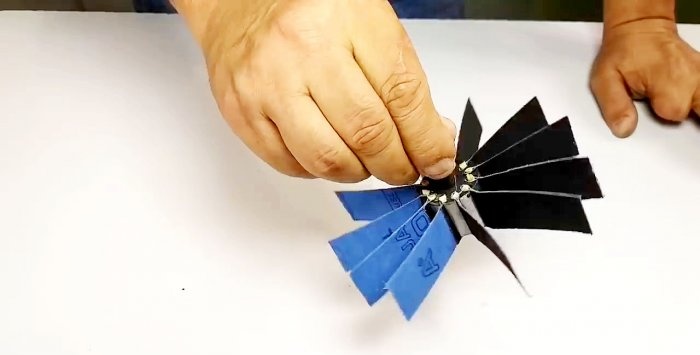

Mount option for sandpaper for the petal nozzle

Also, the anchor can be equipped with a petal nozzle. To do this, a strip of sandpaper is cut into small pieces. Each of them is inserted into its own segment and clamped with a separate skewer.

Such equipment polishes worse, but it can be used on embossed surfaces. If sandpaper on a more rigid basis is used for its manufacture, the quality of processing will increase.

Both nozzles can be put in a screwdriver or drill, as well as clamped in a lathe. This is an eternal snap that never breaks. As soon as one emery is erased, you just need to put another and grind on.