Will need

If there is a ring mill suitable for diameter (another name for a core, hollow or ring drill), then working with curved surfaces, in particular cylindrical, becomes much simpler and more productive.

We will also need a drive for tools, for example, a drill, several conventional twist drills of different diameters and a means for cooling the crown during operation. It can be a special cutting fluid, a suitable machine oil, or, say, WD-40 universal lubricant.

Crown Drilling Algorithm

Drilling the pipe surface must be directed strictly in diameter, otherwise it will not be possible to achieve a positive final result.

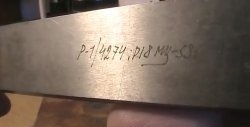

1. We mark on the end of the pipe with a marker the place of intersection of the diameter with the walls of the product (for this there are many methods and devices).

2. Install the pipe so that one of the marks is strictly on top. Using a tape measure, measure from it along the generatrix the required distance and mark it with a marker.

3. Clamp the pipe in a bench vise and tilt the marked point using a core and a hammer.

4. Turn the pipe over in the vice with the reverse side, mark the point opposite to the first, and also wrap it.

5. Using a thin drill and a drill, drill holes in the two pipe points outlined.

6. Next, drill them with a drill of a larger diameter in one pass through, since there is an upper guide and a lower centering hole.

7. Replacing the spiral drill in the drill chuck with a crown with a centering drill, we rotate the pipe in a vice by 90 degrees so that the guide holes are horizontal. This will allow you to make great efforts when working with the crown.

8. Since the core drill is very hot during operation to cool it and facilitate the process, grease the working teeth and the adjacent belt belt in a circle with universal grease WD-40.

9. Insert the centering drill of the crown into the hole previously prepared in the pipe and start the process, adding lubricant to the crown from time to time.

10. After the crown comes out on the opposite side of the pipe, we get a cutout that must be exactly the same in diameter as the configuration of the pipe, which is confirmed by an appropriate check.

11. If several nozzles with equal lengths with curly cuts at the ends are required, then we drill centering holes in the pipe billet at an equal distance from each other, and alternately, using a core drill, we obtain the desired billets.

For reference

We remind you that the outer diameter of the core drill and the pipe to be machined must be exactly the same.