This master class will teach you how to make copies of simple aluminum parts. In our case, the drive gear for the sliding gate broke. In the factory version it is made of plastic. That's what we'll do.

We will need:

- Secondary glue.

- Plasticine.

- Gelatin.

- Glycerol.

- Wax.

- Gypsum.

- Self-adhesive seal.

- Aluminum (in the form of any unnecessary scrap).

Everything you need is purchased at hardware, grocery and construction stores. It is not expensive and is always in stock. For tools and other things, you need various metal containers or pans, a gas stove and a forge.

Manufacturing process

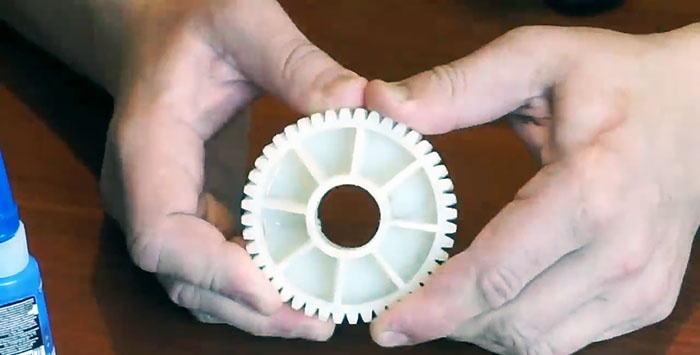

Let's get down to the process itself. We take the parts of the split gear and glue them together with second glue.

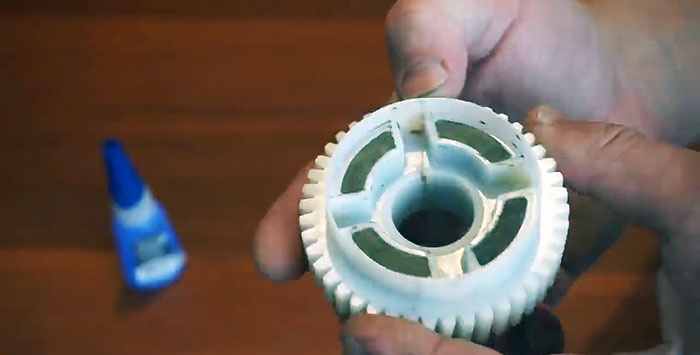

We fill all the technical cavities in it with plasticine to make it easier to cast the part.

Then pour gelatin into the pan and dilute it with glycerin. Melt in a water bath until smooth. When the gelatin is ready, place the part in a small container and fill it with the resulting mass.

Give it some time to harden.Next, we make small cuts to remove the gear. The first form is ready.

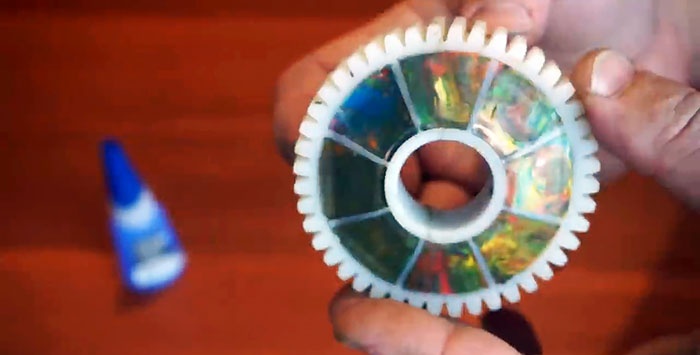

Now you need to melt the wax and cast a part from it.

When the part is ready, be sure to compare its size with the original one.

Ours came out a little less than it should have been. The issue was resolved with a window seal. You need to stick it on the gear teeth and cut off the excess.

Then we repeat the previous steps. We melt the gelatin mold and fill the part again, remove it and fill it with wax. Now it's exactly the right size.

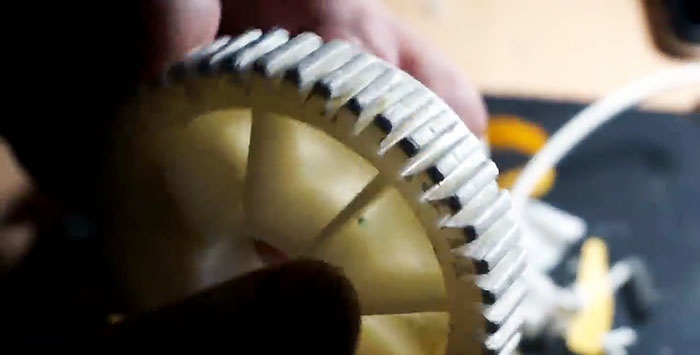

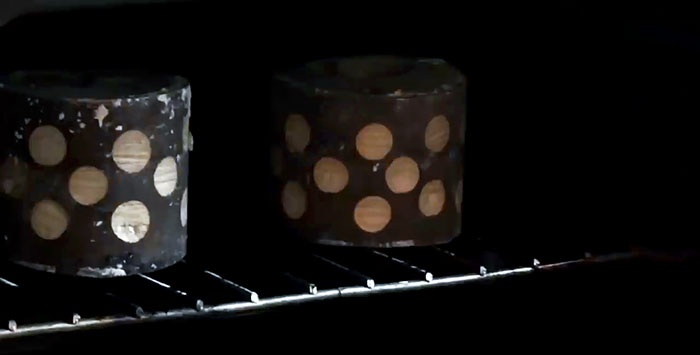

The next step is to dilute the plaster in a metal container and pour it into the wax part. Let the plaster harden and heat the container in a forge to remove the wax from it.

We tried to melt wax from plaster in the oven, but it didn’t work out completely, which had a bad effect on the quality of the final part.

When the plaster mold is ready, we melt the aluminum in a forge.

We pour the molten metal into plaster, cool it in water and get the finished part.

Overall it looks good, but needs some minor improvements.

For this, a file and a hacksaw for metal are enough.

A lathe will make processing easier, but it is not necessary.

All that remains to be done after processing the part is to install the gear in its place.

Do not forget to lubricate the moving and rubbing parts of the mechanism. This way they will last much longer.

Important point! Be extremely careful when pouring metal into a plaster mold. If the plaster is not completely dry, then when the metal being poured is very hot, the water will begin to evaporate quickly. This will cause the mold to begin to “spit” steam and small droplets of hot metal.

Conclusion

Nowadays, plastic parts are often used in highly loaded mechanisms.This is a clever marketing ploy that forces us to shell out for expensive parts. The new aluminum gear is easy to manufacture, will last much longer and will significantly save your budget.