Materials:

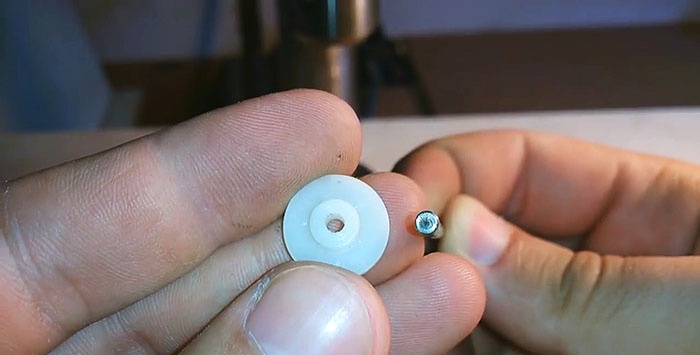

- drill chuck with a shaft or SDS-plus adapter;

- piece of chipboard;

- epoxy adhesive;

- 2 bolts with nuts.

Console Assembly

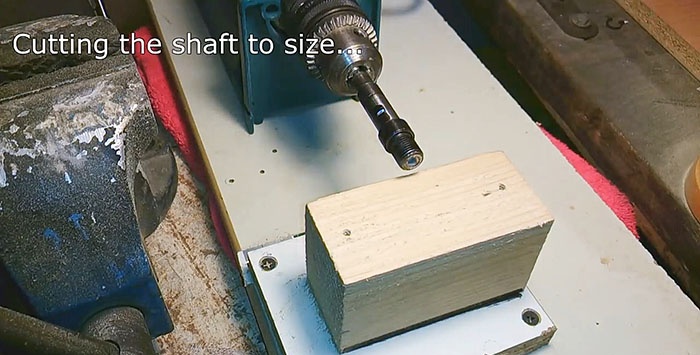

In my case, the prefix will be made of a cam cartridge with a shaft. If you don’t have an old drill for disassembly, you can just buy a cartridge with an SDS-plus adapter. In any available way you need to trim the shaft or adapter. It should be shortened so that the tail corresponding to the thickness of the available chipboard comes out of the cartridge. Using an engraver, I cut the shaft at around 18 mm.

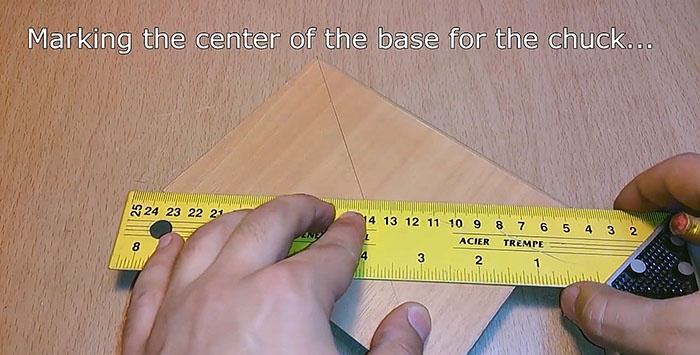

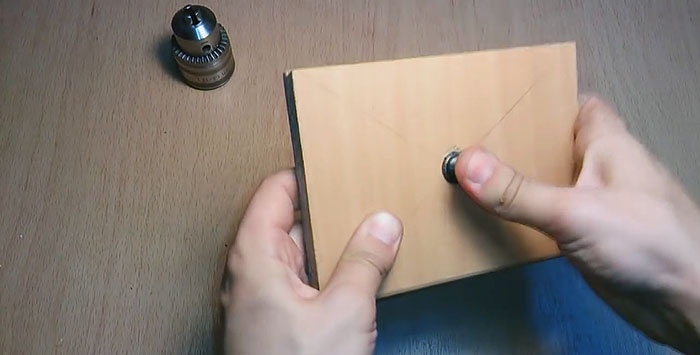

Next, you need to take the chipboard. It will be used as a stand on the table of the drilling machine. The size of the workpiece is determined individually, but 15x20 cm is quite enough. The center is marked on the chipboard. To find it, you should draw diagonals between the corners.

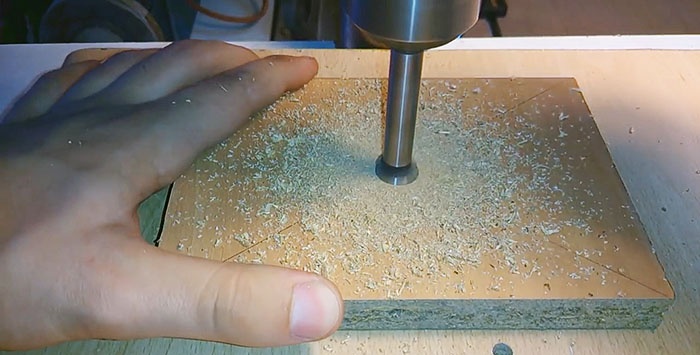

At their intersection, a hole is drilled 1 mm larger than the thickness of the trimmed tail of the adapter or shaft.

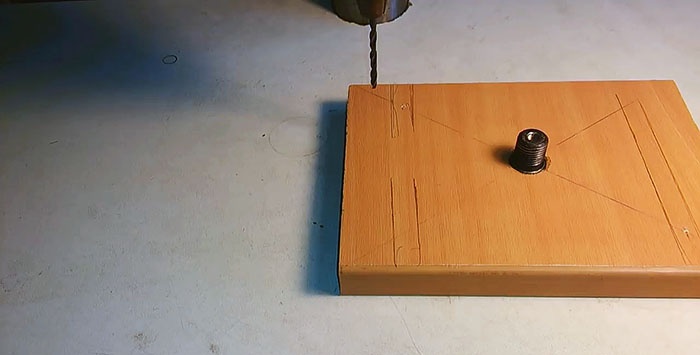

The hole is coated with epoxy glue, after which the cartridge holder is pressed into it. It remains to wait until the epoxy solidifies.

Chipboard with a shaft is placed on the table of the machine and holes are made for fixing it. It is enough to drill 2 holes diagonally.

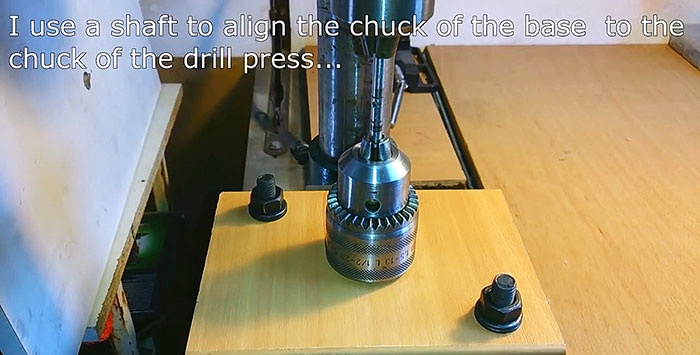

The base of the attachment is slightly clamped with bolts and nuts on the machine table. A cartridge is screwed onto the protruding shaft.

A drill or flat bar is inserted into the machine. At the same time, its protruding part must fall into the cartridge of the console to be squeezed by its lips. This allows for centering. After fixing bolts must be clamped securely.

How to use?

The resulting design copies the principle of the lathe. Now motionlessly clamping the drill in the attachment of the attachment, and fixing small parts for drilling in the machine, you can make even centered holes.

Check by rotation on the shaft.

This design will be useful when expanding the bore diameter in gears, pulleys, etc.