The breakdown seems to be insignificant, and you can continue to work. But not so simple; with a more or less serious load, the wheelbarrow begins to lead in the direction from which the pad broke. This is very inconvenient when transporting heavy loads. Then I decided to remove the second overlay, for symmetry! I thought it would help.

Indeed, it helped - it stopped driving the car to the side. But she began to creak hellishly! Ears curl up! No lubricating oil helps. For a long time I could not stand it, and went to the nearest hardware store, for the part I needed, which, of course, was not there. To drive around the city, in search of the right thing, there was not the slightest desire. Then I decided to repair the broken thing myself. Today we’ll consider one of the options for how to assemble a thin plastic lining, chopped in half, together. This advice will greatly help those who are in a similar situation. This may not necessarily be a pad from a wheelbarrow. In this way, you can restore any plastic thing or part. At least until the original is purchased from the store.

You will need:

- Pliers.

- Pin.

- Glue second.

- Composite adhesive, type "cold welding".

- A drill, the thickness of a cooked pin.

- Bor machine or a small drill.

- Small grinding disc for a bor machine.

Repair a broken part

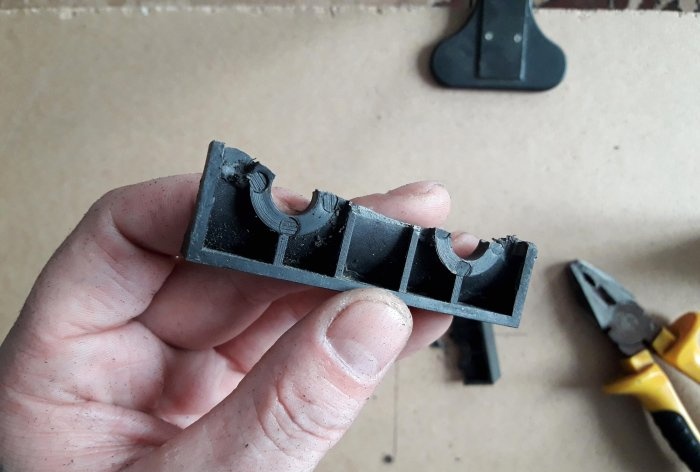

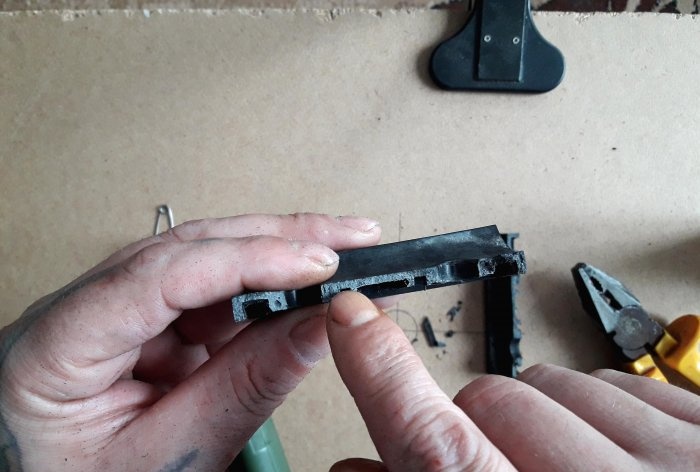

First you need to check if any small pieces have fallen off and examine the repair object in more detail. If the repaired part has stiffening ribs, then the longitudinal ones will have to be removed. This can be done with pliers and a boron machine with a small grinding disc.

Further, in the most thick-walled places, with a drill of two millimeters, you need to drill holes into the part. Like this:

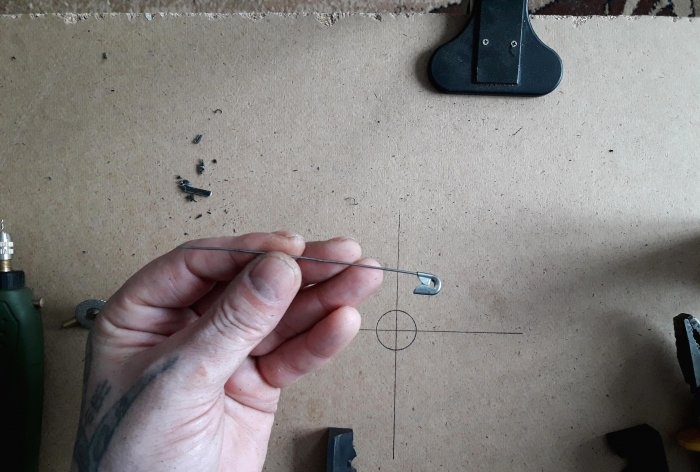

A depth of 4-5 millimeters. We will need these holes to reinforce the part. For greater strength. Next, we take the prepared pin, straighten it, and break it (or bite it off with wire cutters - who cares!) Into eight millimeter pieces.

Now, using a match, or thin wiring, lubricate the holes on the drilled half of the broken part, and stick the pins obtained from the pins into the holes.

We do everything extremely efficiently so that the glue does not seize in empty holes. Next, drill holes in the second half of the broken part. Strictly opposite the pins sticking out of the first half. If everything worked out as it should, we lubricate both halves in a split place with second glue, and stick into each other.

It is necessary to compress the glued parts. At least thirty seconds so they grabbed.

Now it's the turn of composite glue. I use the type of "cold welding" - a very convenient glue. There is not so much fuss with it as, for example, with the liquid components of epoxy glue. Yes, and it freezes much faster, but they are the same in terms of reliability of fastening.

In general, we break off, or cut off, the piece we need from the total mass, spray the palms with water, and carefully stir and knead the glue in the palms. To obtain a homogeneous mass.

Next, grease with a second glue the inner surface of the part being repaired, the one with which we broke the longitudinal stiffeners. And we sculpt cold welding on a greased surface.

After all the above procedures, we leave the part for several hours so that the glue is already set for sure, as it should.

Well, and in the end, install the restored part in its original place.

It turned out very well. Leads nothing, does not creak. You can load again as much as you can take, and how much the wheels are designed for!

The work itself took no more than an hour. The only negative: I had to wait a few hours until the glue finally set.