If the latch on the carburetor throttle control cable is torn off, it can be quickly restored on its own, and you won’t need to buy a new cable. To do this, it is enough to cast a new boss from tin.

What do we need

- Collapsible mold for casting;

- Gas-burner;

- Flux and tin (solder is best taken in the form of a wire);

- Vise.

Casting mold

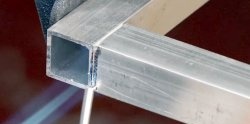

It will take two small pieces of industrial aluminum sheet with a total thickness of 1 cm. It is desirable that the bottom sheet is 6 mm and the top is 4 mm.

They should be pulled together with an ordinary bolt.

Next, we drill a hole for the future casting with a diameter and depth of 8 mm. It must be positioned in such a way that between the edge of the plates and the hole is about 5 mm, not more. From the end, we drill a hole for the cable so that its center is at the junction of the sheets and in the center of the cavity under the fill.

Form preparation

To uniformly fill the entire volume of our form with solder, it is necessary to treat the surface with flux.

He does not need to be sorry - an overabundance will not be superfluous at all. We fill the form with flux and heat it with a gas burner.

We direct the flame to the sheet material of the form, and not to the hole. Aluminum has a high thermal conductivity and very soon the flux will begin to boil, qualitatively treating all the surfaces of the filling hole.

The edge of the cable that will be part of our casting also needs to be treated with flux so that when immersed in the melt, the solder is firmly “stuck” to it.

Casting the boss

We take the tin solder, continuing to warm the base of the form, and immerse it in the hole.

We are waiting for a complete melt. Do not save - the volume of the form must be filled in excess. We insert the end of the cable with the applied flux layer to the stop, turning it a little and moving it in different directions.

We close the burner and wait for the solder to cool down slowly. Using a chisel or knife, align the top of the fill, removing excess metal, until it solidifies.

In no case should you specifically cool the form with water - a rapidly solidified tin will become very fragile, and the boss will quickly fail. The whole complexity of this section of work is to keep the cable in the correct position until the solder solidifies.

After that, you can free the mold and immerse in water for final cooling, and only then we unwind the sheets - the boss easily detaches from the walls.

After all, we process the boss with a file to remove all excess castings.

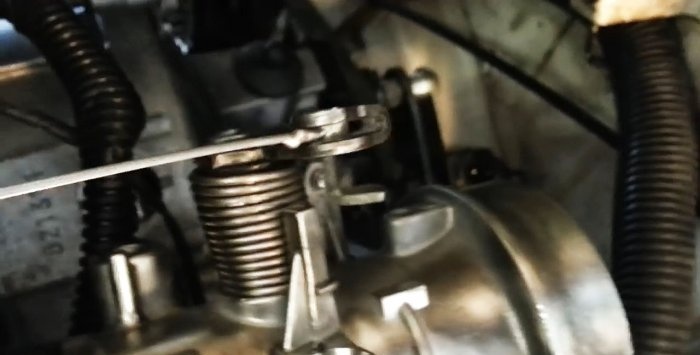

Now everything can be installed back to your favorite transport:

Summary

When working with an open flame and molten metal, you must follow the safety rules (it is strictly forbidden to carry out such work near combustible substances) and be careful not to get burned.

As you can see, the recovery procedure is very simple and with the preparation of the form can take up to 10 minutes, no more. Comparing the cost part and the cost of a new cable, you can get a material assessment of the effort.