Essential supplies

Since the structure of any type of wood is fibrous and not too dense, the wood glues well. Therefore, first of all, we will need:

- CA glue, also called cyanoacrylate or super glue. One of its important qualities is quick drying, although not fast enough, as desired.

- To speed up its drying, you can use an aerosol activator, which ensures rapid strength gain (hardening) of the glue. It is better to choose the same brand as the super glue.

- A good quality wood putty that is effective and does not shrink. It comes in different colors, so choosing the right color for a particular type of wood is not difficult.

- Ordinary household electric iron, piece of cloth, etc.

Woodworking error correction process

Let's look at typical defects when working with wooden products and how to deal with them.

Eliminating chips

Sometimes, when processing workpieces, a piece of wood breaks off.

If it is intact, the problem can be solved quite simply: you should use glue to install it in place. The situation becomes more complicated when this fragment could not be saved or it got lost somewhere. Then you will have to use filler, i.e. putty.

To do this, you should determine the type of wood to select the putty by color. In our case, the workpiece turned out to be made of maple. We select the appropriate type of putty and, using a small spatula, completely fill the gap or deep scratch with the selected composition.

Give the putty enough time to dry completely. This process proceeds quite quickly, since the composition is water-based. The jar should always be kept closed so that the contents do not dry out and then it can be used as needed.

After the putty has completely hardened, we process it with sandpaper to achieve the desired profile. As expected, the color-matched putty does not stand out against the background of the natural color of the maple blank.

Now we take a suitable colored pencil and draw texture lines along the polished surface of the putty, observing their natural thickness and color saturation. To increase the strength of the restored area on the workpiece, it can be coated with colorless varnish.

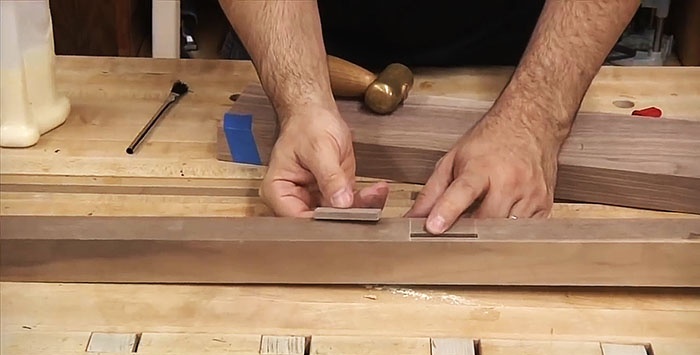

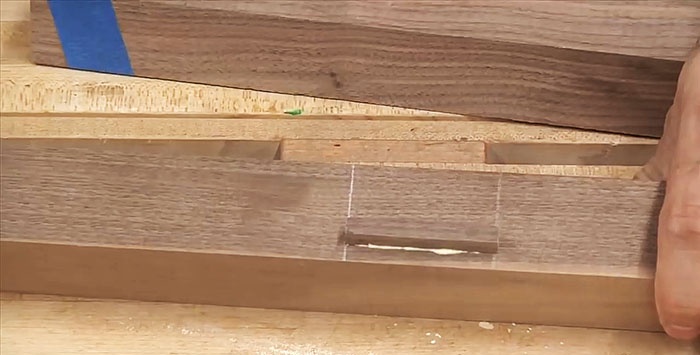

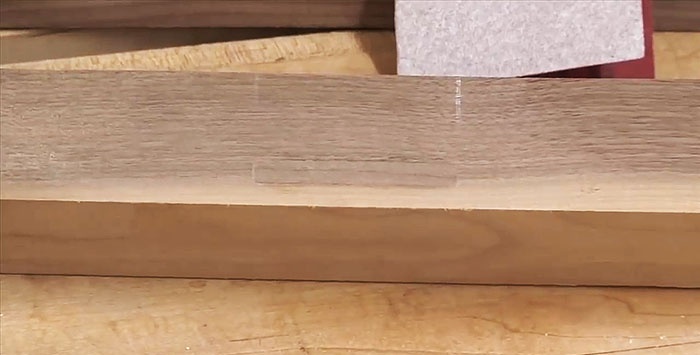

Eliminating erroneously made holes

It happens that a recess, a through hole or a groove is made in the workpiece in the wrong place or to eliminate a serious defect penetrating into the body of the workpiece. To disguise such interference, we make an insert slightly larger than a groove, but with a taper towards the bottom. This will allow it to easily enter the recess and, as it sinks under the blows of the mallet, completely fill the hole along the outer plane. For reliable fastening, the tenon and groove should be covered with glue before installation.

If part of the tenon remains outside, it can be cut off with a plane and sanded with sandpaper. The main thing in this case is to choose an insert from the same wood as the workpiece, with approximately the same texture.

Repairing corner chips

Sometimes, at the very end of processing a workpiece, one careless movement leads to a small, but oblong piece being separated from the array. If you don’t lose it and keep it intact, then you can glue it in place using super glue, lightly pressing it with a spatula.

To make the glue set faster, cover the working area with an aerosol activator. After the glue has completely hardened, lightly sand the area with fine sandpaper to remove excess hardened glue.

Restoring large corner chips

It happens that at the end of an almost finished workpiece, a rather large piece of wood with an uneven cross-section breaks off. Restoring a part becomes more difficult if a broken fragment is lost or has broken into pieces.

In this case, it is better to aggravate the defect: cut it off with a chisel or plane and give the base of the damage a flat surface. This will make it easier to eliminate the deficiency.To do this, it is enough to use CA glue mixed with an aerosol activator to glue a obviously larger fragment of wood and, after waiting for a strong setting, process it from all sides until the required shape is obtained in three planes.

To do this, we will need a plane, sandpaper and a saw if the glued fragment protrudes beyond the edge of the workpiece.

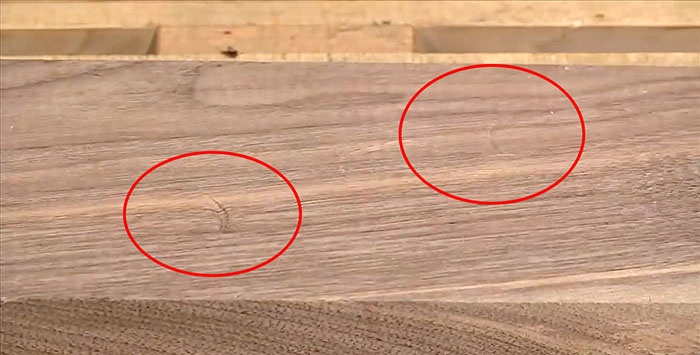

Repairing dents in wood

If a heavy object or tool is dropped onto the surface of a wooden product, a noticeable dent will remain on it, which will clearly not improve the appearance of the workpiece. What happens? Wood fibers are compressed and compacted by impact, resulting in a dent.

Is it possible to return the wood fibers to their original position? Yes, such a method exists. Pour water onto the damaged surface of the workpiece so that it fills the dents with a “reserve”.

Cover the damaged area with a cloth that absorbs water well. If you now move a hot iron over it, the water will begin to evaporate and the steam, acting on the crumpled wood fibers, will begin to straighten them. Increasing in volume, the deformed fibers will return to their original state and eliminate the dent.

To visualize the process of removing dents, it is necessary to run an elongated block of chalk flat over the place where the defect was. If the dent is not completely removed, an unpainted area will remain, and steam treatment should be continued.

This method can be used before sanding multi-layer plywood to repair minor dents and scratches that may have occurred during shipping, handling and storage. After this treatment, sanding the plywood surface will not take much effort and time, but will ensure high quality.

Finishing touch

Sometimes craftsmen add sawdust to super glue or epoxy resin and use this mixture to correct mistakes. But it should be taken into account that even with an admixture of sawdust they can change the natural color of the workpiece being repaired or leave noticeable stains.

When using such mixes, you often have to add paint to adjust the palette. To preserve the natural color of the restored workpiece, it is best to use colorless products.