Sometimes, when making various homemade products, it is necessary to drill a perfectly positioned hole on the side of the tube or rod. This cannot be done without prior preparation and tools. The main difficulty is finding the geometric center of the future hole. Below we will consider one way to do this in practice.

Required tools and materials

We will need:

- hacksaw for metal;

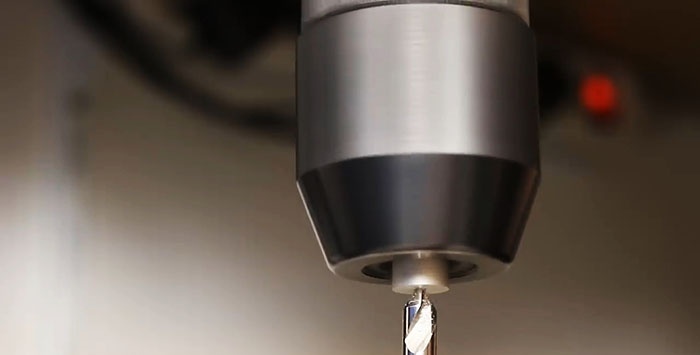

- tabletop drilling machine;

- punch and hammer;

- collet chuck;

- center drill;

- regular twist drill with a diameter of 2.5 mm;

- metalworking and mobile vices;

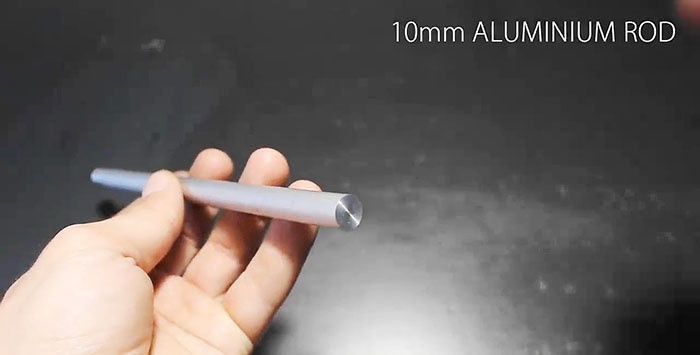

- aluminum rod with a diameter of 10 mm;

- a piece of coarse sandpaper;

- cutting fluid (coolant).

The procedure for drilling a transverse hole in a workpiece

There are many ways to do this. In our case, we use part of the rod itself as a conductor, having previously processed it.

1. Clamp the rod in a vice and use a hacksaw to cut off a small piece about 20 mm long.

2.We insert and clamp the sawn-off part of the workpiece in the drill chuck with the cut side down.

3. Place sandpaper on the table of the drilling machine and, holding it with your fingers, turn on the spindle of the machine and press the end of the piece of rod against the sandpaper until a flat and smooth surface is formed.

4. Using a punch and a hammer, mark the geometric center at the end of the blank of the future conductor.

5. Re-insert and clamp the workpiece with the punch end down in the chuck of the drilling machine.

6. Then we fix the collet chuck mandrel in a movable vice, clamp the centering drill in it and align it, moving the vice, exactly under the punched place in the piece of the rod.

We turn on the machine and finally determine the location of the future through axial hole, which we then finally form with a 2.5 mm twist drill.

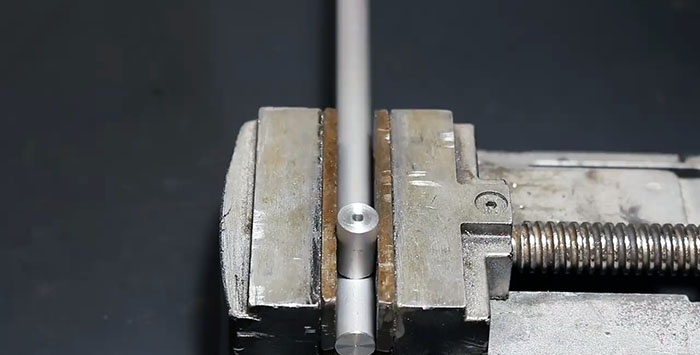

7. We place the rod in a bench vice, and on top of it we place perpendicularly a cut piece of the same rod with a central axial hole, a kind of jig.

8. Securely clamp both elements in the jaws of the movable vice. Pour some coolant into the hole. We center the homemade jig by moving the vice relative to the drill and drill a hole in the side of the workpiece.

9. By changing the position of the conductor cylinder on the rod, you can make any number of transverse holes, if necessary.