There was a need to process a large piece of wood, for example, to create a sculpture for the garden or a chair from a stump.

With a regular chisel, all this will take months to do. A branded instrument is not cheap, you have to go somewhere and buy it. After the work is completed, it will lie uselessly and gather dust for years.

But in a home workshop, you can make the necessary tool yourself. If you have a medium-power drill, welding, emery and a grinder with a cutting disc, then go ahead and get to work!

Let's start making an electric chisel

We take a steel bar with a diameter of 12 - 14 mm, the main thing is that it is clamped into the chuck of an existing drill.

Use a disk to cut a workpiece 45–55 mm long. At one end we make a flat cut at an angle of approximately 60 degrees to the longitudinal axis of the rod.

We select a washer with a thickness of 3 - 5 mm, with an outer diameter of 22 - 28 mm. and internal 10 - 16.

We weld the washer symmetrically through its hole to the cut oblique end of the rod. To be safe, you can also scald the washer on the opposite side.

Immediately after welding, it is advisable to heat the part by dipping it in water.We sand the end surface of the washer - it will be working, so the operation must be done as carefully and cleanly as possible.

We install the resulting part into the drill chuck and clamp it tightly.

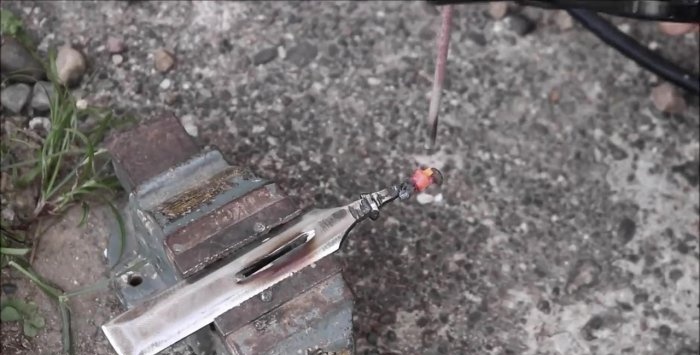

We fix an old, but working and sharpened chisel in a vice.

In the middle of the blade, closer to the shank, we use a cutting wheel to make a longitudinal groove, 40 - 50 mm long, 3.5 - 4 mm wide.

For the body of the tool being created, we take a wooden block with dimensions 80 x 80 x (250 - 300) mm.

Using a pencil or marker, draw the outline of a drill with an oblique washer fixed in the chuck onto a wooden workpiece.

Then, first with a chisel, then with a cutter or a graver, we adjust the resulting internal cavity under the drill.

We repeat the operation on the second half of the workpiece for the body. Ideally, the cylindrical front of the drill should be clamped tightly between two blocks, with the chuck and washer rotating freely inside.

We select a bolt with a hemispherical head, with a rod diameter of 4 - 6 mm, and a length of 25 - 40 millimeters.

We weld the bolt and the shank of the chisel, quench it in water. Afterwards, we clean the weld seams using sandpaper.

Then use a chisel to select a groove for the chisel in the wooden body.

We put a spring of suitable size and stiffness on the tool shank. We select a washer or nut as a support for the second end of the spring. We are modifying the wooden body for support.

We secure the chisel blade in the body with two self-tapping screws or screws with washers. The chisel should have a free longitudinal movement of about 10 - 15 mm, and not dangle in transverse directions.

We install a drill in a wooden case. We check the operation of the mechanical part.

Everything is working properly!

We adjust the second part of the tool body. Then we refine the outer surface of the case.We remove excess material and sand the surface of the wood. We carry out the final assembly of the tool. It is advisable to “plant” the self-tapping screws securing the chisel blade with glue. This ensures that in the future, the fasteners will not come loose when the tool is used.

We clamp the drill in the body of the resulting tool with four self-tapping screws or bolts with nuts installed in the mating part of the body.

Don’t forget about safety precautions, we wear gloves, protect our eyes and face with a mask!

Turn on the electric chisel. Works great, easily removes chips and goes deep into the wooden workpiece! It is possible that her appearance is somewhat rough, but she is comfortable and productive to work with.

With such a tool, Vovka from the cartoon about the Far Away Kingdom would definitely make the old woman a new trough!