It was necessary to make a welding unit for use in the garage and in the country. Simple but powerful, up to 200 A output current to weld steel up to 12 mm thick. electrodes “four” or “five”.

Necessary

- Four new or used power transformers from a microwave oven;

- Insulated stranded wire with a cross section of at least 50 mm2;

- Sleeves for crimping wires and press pliers;

- Simple metalwork and carpentry tools;

- Multilayer plywood for the apparatus;

- Multimeter and remote thermometer;

- Various small things, fasteners, paint and more.

Manufacture of electrical parts

The transformers themselves can be bought new or used, in microwave repair shops, with a decent discount.

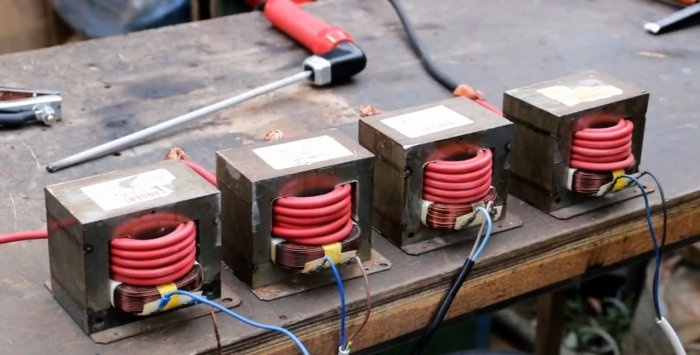

We remove the second winding. You can use a cutting disc or a conventional hacksaw for metal. The main thing is not to damage the primary winding!

We knock out the remains of the cut off “primary” with a beard or any suitable steel core.

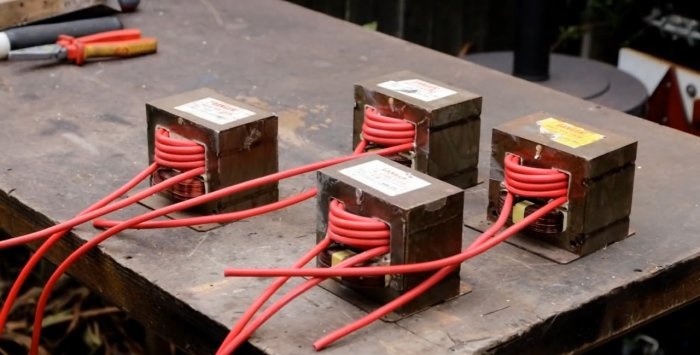

Then, in a free “window”, carefully lay 10 turns of cable.

We leave conclusions on 15 cm.

Repeat the operation with the remaining transformers.

Checking the electrical part

It is necessary to check the electrics of the future welding machine.

ATTENTION!

All further electrical installation work should be carried out ONLY with a de-energized device!

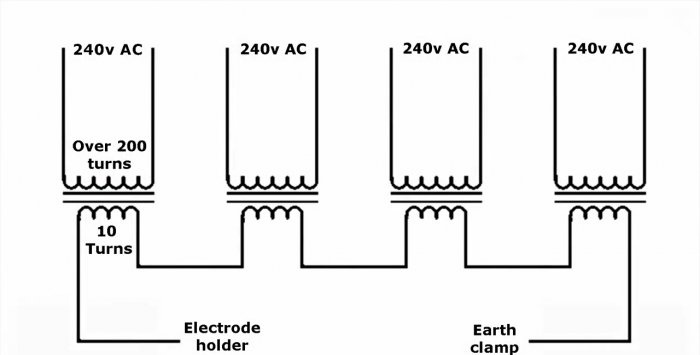

We connect the twisting of the winding according to the scheme.

Network, former secondary, in the "parallel."

The output windings are assembled in series.

In this case, it is necessary that the outputs of one winding are connected to the input of the subsequent!

We connect the network windings to a powerful 220 V outlet. We check the current consumed by the unit, in the absence of load.

About 11 A., too much, but bearable.

We measure the voltage at the output of the combined power welding windings. The result was a voltage of 35 - 37 V. Each transformer has 9 V.

Then we check the possibility of ignition of the arc, and try to weld a pair of steel parts.

Brews! The seam is excellent.

During welding, the input current 32 - 35 A, the arc current 170 - 190 A.

We check the heating of transformers, it does not exceed 80 0C. Allowed.

Body

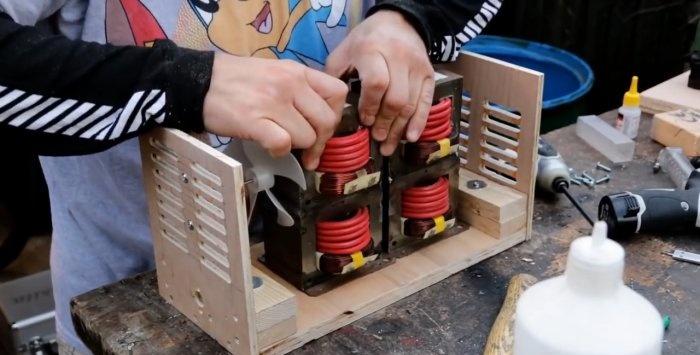

We weld transformers in two.

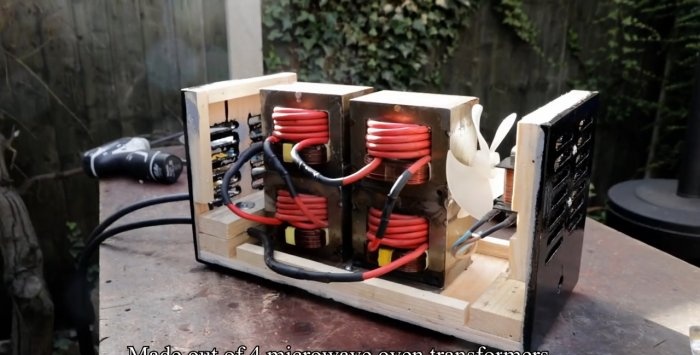

You can make a body of metal, you can pick up something ready. It was easier for me to make from plywood.

The housing must have large ventilation holes.

We install a fan for forced blowing of transformers.

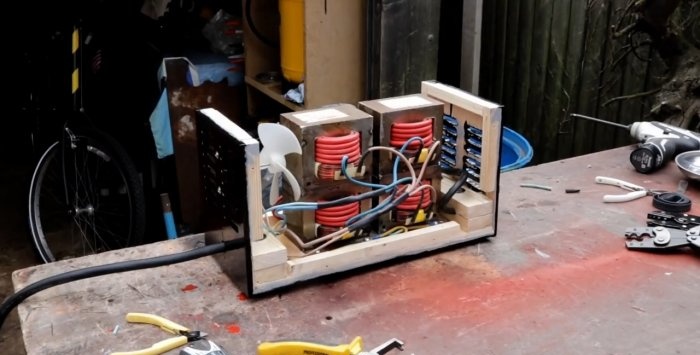

Final assembly

We mount all the nodes and parts in the housing. We make the connection of the leads of the windings, network and output welding, metal sleeves of the corresponding diameters. We compress the sleeves with press tongs.

We isolate the joints with heat shrink tubes, heating them with a hairdryer.

Close the lid, the device is ready.

Work check

We weld two 6 mm. steel plates. The arc is smooth, there is no "drawdown" of current. The seam is obtained with a deep penetration.

Through the hole in the case we check the transformers for overheating. The temperature is slightly more than 40 0C.

Repeat welding with 12 mm. scraps of steel. The result is again positive.

"Welder" turned out!

True, it is worth remembering that the transformers in the device are relatively small. Therefore, the most important characteristic for the welding unit PV (duration of inclusion) or PN (duration of load) is small 20-30%. Cooked for 3 minutes, let the apparatus rest for 7-8 minutes. At this time, you can change the electrode, rearrange the parts to be welded, just rest.

To increase the performance of the device, reduce its heating, it makes sense to put a more powerful fan or put a second. One will blow air, the other will draw.The cooling efficiency will increase.