The method of durable soldering of products from various metals is carried out by heating the soldered parts with a gas burner and using brass as solder. With the massive spread of copper automotive radiators, brazing was the only reliable way to eliminate leaks. Such soldering is widely used in the manufacture and repair of household and industrial equipment, air conditioners. In addition, brass brazing allows you to securely fix the refractory cutting parts on the body of the cutter or drill string. Brazing allows you to collect small hand-forged artworks (chandeliers, gratings, fireplaces, etc.).

Materials and Tools

Brazing is carried out using three main components: a gas burner, giving a temperature of at least 1000 degrees.

Brass solder (in the form of wire or tape).

And flux - sodium tetraborate or borax, mixed with boric acid powder.

Modern household gas burners use refined propane, sold in mini cylinders, or special mixtures of gases. More complex burners with separate gas and oxygen supply accelerate heating and the entire soldering process.

The need for this flux is due to the zinc content in brass. Zinc, when brass wire is melted without borax, causes boiling of solder, which affects the quality of the weld and its strength properties.

In addition to the main components, we will need auxiliary tools:

- sandpaper and files for stripping parts;

- various vices and clamps;

- holding hand tools (pliers, long-nose pliers, etc.);

- liquids for degreasing and washing and descaling from finished joints (acid solutions);

- refractory gloves and other personal protective equipment used in welding work.

When conducting open fire work, it is necessary to strictly observe the fire safety rules. Indoors, you must have a fire extinguisher, water, asbestos cloth or tarpaulin. It should be remembered that zinc fumes are toxic. AES is required, interruptions in work and ventilation of the room.

Brazing process

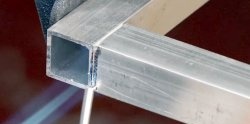

It is necessary to prepare soldered parts. Suppose we need to make a small frame structure of thin-walled steel tubes with a diameter of about 5 mm. When soldering two tubes of small diameter end-to-end, you need to make a notch at the end of the tube to be soldered. This will increase the bond strength. Parts must be placed in clamping devices and the joints pressed together. This is a necessary condition for performing high-quality brazing brazing, as the hands will be occupied by the torch and the supply of solder.

We ignite the gas burner and begin to heat up the soldering place until red appears.

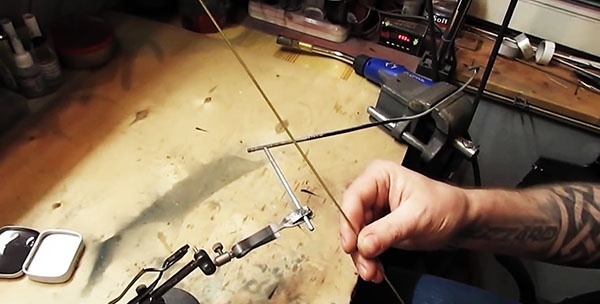

We also heat the brass wire (solder) and lower the heated end of the solder into the drill. Borax sticks to solder wire.

We briefly move the burner flame away and apply the flux directly to the junction of the steel tubes.The borax melts quickly and covers the entire soldering zone. If you do not remove the flame, then the borax will simply blow away from the brass wire.

After that, soldering begins - slow melting of the brass solder, its manual feeding and filling it with the joint between the parts.

During the work, visual control over the quality of the seam is carried out. If a fistula is found in the lower part or an area not covered by solder. It is better to turn the part over and solder this place again.

After stuffing your hands, you can solder the "ceiling" joints. Soldered parts should cool in the air.

Then you need to remove the scale by placing the item in a solution of edible citric acid.

To check the quality of the seam, bend the product.

Very durable!

Precautionary measures

Brazing is an open fire work. Strict observance of all fire protection measures is necessary. In addition, working with zinc fumes can cause severe poisoning of the body. Protective measures must be taken. Mini gas cylinders may leak in the valve, resulting in explosions and fires. Constant monitoring of the operation of the gas burner is required.