Over time, in Soviet houses, sooner or later it is necessary to change sockets. They become loose, modern Euro forks do not fit into them, there are other reasons. Wiring in old buildings of the Soviet Union is made of aluminum. The aluminum single-core wire is quite fragile, and if it also got hot at the connection points, then when you disconnect the old socket, it will definitely break off.

As, in fact, happened in my example. For a long time, the wires heated up due to a loose contact, so much so that the insulation melted. Now there are small bits of wood sticking out of the wall and in the socket box and you can’t just install a new socket. This problem is quite common, especially during repairs. There is nothing terrible here, and, in principle, everything is easily fixable.

Will need

- Heat shrink tube (preferably a set with different diameters).

- Two WAGO terminals.

- Two copper or aluminum wires, the number of cores does not matter, the main thing is the square footage is at least 1.5 square meters. mm.

- New socket.

Installing a socket in a socket box with short wires

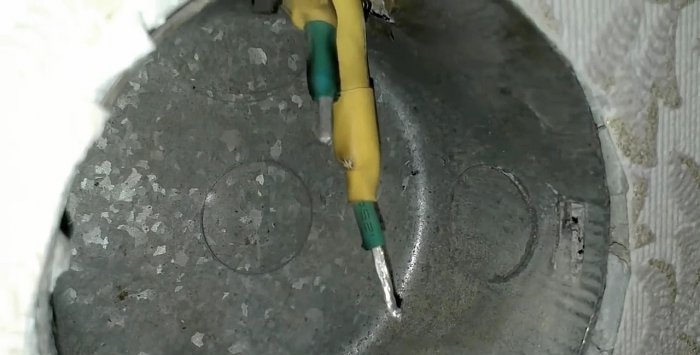

Let's start by turning off the electricity in the house.Next, we ring all the contacts of the socket with an indicator screwdriver with a neon light bulb to determine the phase. In this way, we will make sure that the electricity is definitely turned off and nothing threatens your life.

We unscrew the front panel and disconnect the contacts of the old socket. As I already said, the wires got hot, the insulation on them melted, dried out and became brittle. Since it crumbles, it needs to be removed. Instead, select heat-shrinkable tubes of the appropriate diameter.

I will extend the wires using WAGO terminal blocks. But these convenient devices must be installed correctly, otherwise they can play a disservice. So: the minimum length protruding from the wall must be at least 2 cm and 1 cm must be well cleaned, not wrinkled or bent. These are the main rules. Therefore, everything that is bent needs to be straightened, and everything that is flattened needs to be cut off. And the rest is insulated with heat shrink. You can shrink it with a special hairdryer or a regular lighter.

Here's what I got:One wire broke, but it's not a big deal. We put the terminals on until they stop and snap them into place. Their big advantage is that now the wiring can be done with copper wire. I took stranded. It is soft and will not break off.

I took a double socket, which will expand the functionality to replace the old one.

We connect and install.

It is fixed in exactly the same way as the old one - resting against the side grooves of the socket box. But as you can see, there are also longitudinal fastenings for direct fastening to the wall. This is simply an excellent solution, especially for those whose socket box is broken and it is not possible to securely secure all the insides.

Install the cover panel.

Turn on the electricity and check the operation. Everything is fine. The terminals will withstand all the necessary loads in a given location. By the way, on Ali Express they are quite inexpensive - WAGO. This can save on repairs.