Quite often, such a nuisance occurs as a wire (cable) breaking near the plug. This happens especially often with wires that are subject to constant vibrations and movements. For example, for headphones, chargers, probes multimeter and things like that. We notice the gap, as a rule, only after the thing we are using stops working. And it’s actually quite difficult to notice this. If only by chance we see... A rupture does not occur immediately, with the exception, of course, of rough mechanical impact. The cable braid is usually damaged first.

After a certain period of time, the strands of the copper wire themselves break due to constant kinks. To prevent this trouble, you need to inspect the wires every time before starting work. But who will do this inspection and when, if you can’t wait to get to work as soon as possible... Today we will talk about probes multimeter. So, so that work doesn’t stop at the most inopportune moment, I suggest making spare probes for the multimeter. The work ahead is not dusty, not boring or difficult and, I would even say, interesting.

Will need

- Soldering iron, tin and flux.

- Scissors.

- Stationery knife.

- Heat-shrinkable tubes (various calibers).

- Secondary glue and soda.

- Two thin markers.

- A tube or pin with a diameter suitable for the probe connector in a multimeter.

- A pin from a CD drive (on which the laser head moves), or a regular knitting needle.

- Lighter.

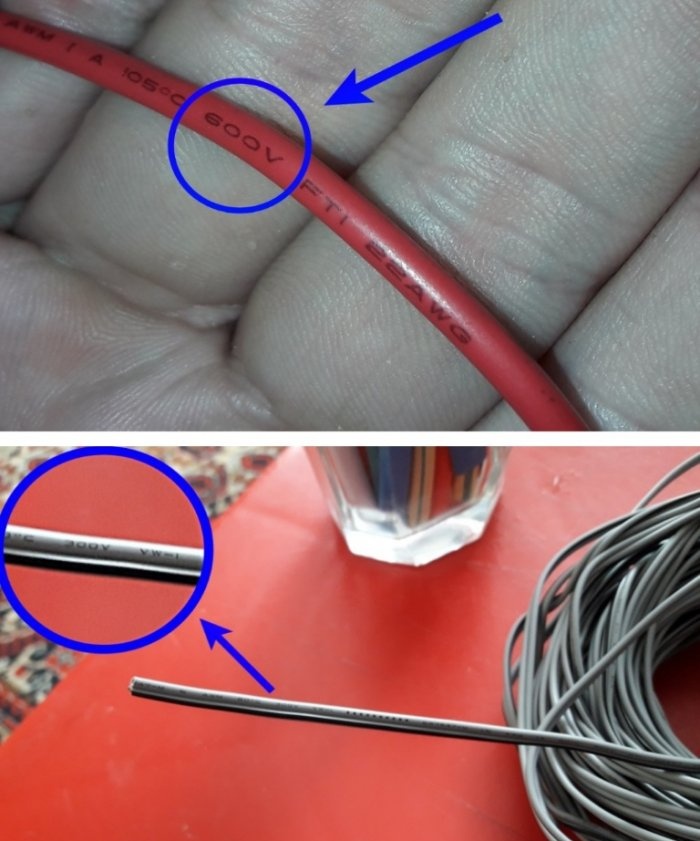

- Electrical wires, copper, flexible (with a maximum operating voltage of at least 300 volts).

- Insulating tape.

- A drill with a cutting disc, or good wire cutters, for separating a hairpin (or knitting needle) into fragments.

We make probes with our own hands

First, let's prepare the wires. Unfortunately, I didn’t find red and black cables in my household, so I took a neutral gray one for both probes. The cable is designed for a maximum operating voltage of 300 volts, despite its small thickness. Cables from “original” probes multimeter designed for a maximum operating voltage of 600 volts.

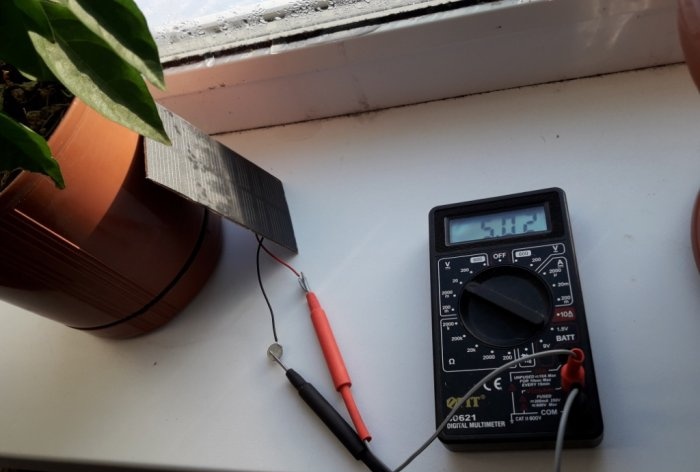

So new probes for home use will do just fine! Moreover, this is only a temporary replacement for failed probes until the original ones are purchased. So, we measure the new wires, along the length of the old ones, and cut off the necessary pieces.

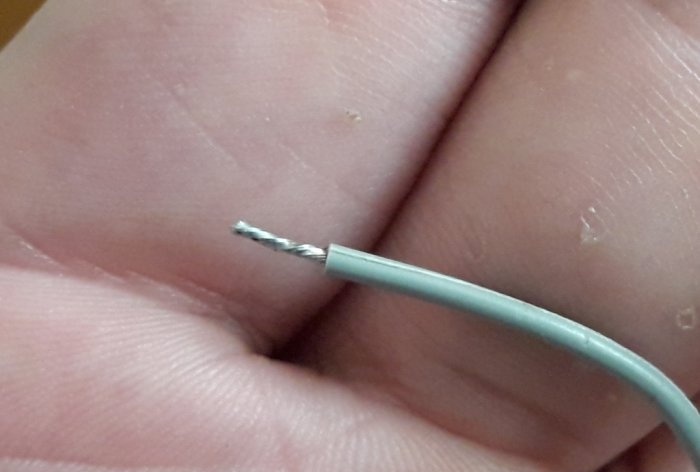

We clean 5 mm with a stationery knife. from the ends of both wires, and tin them with tin for further convenience when soldering.

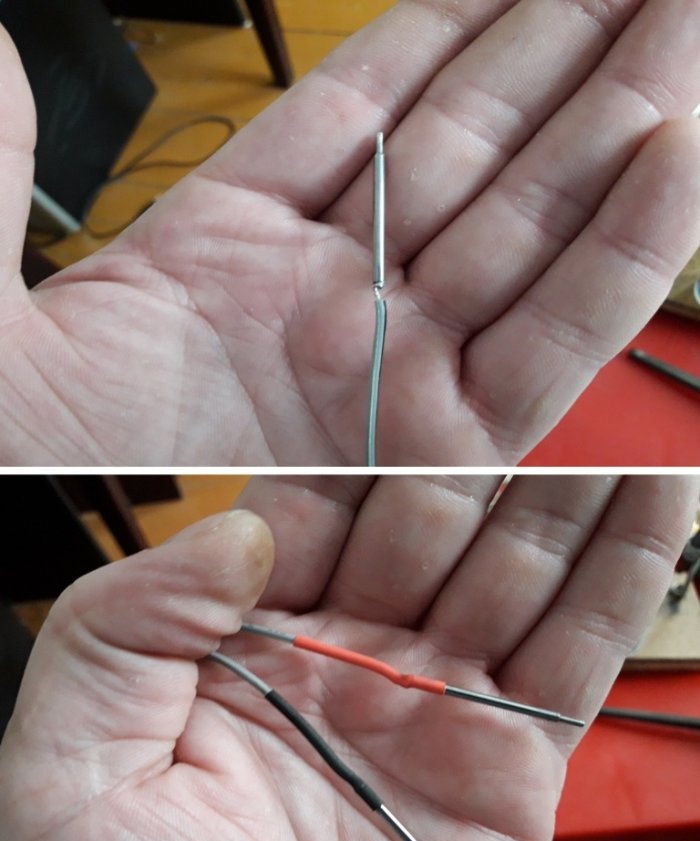

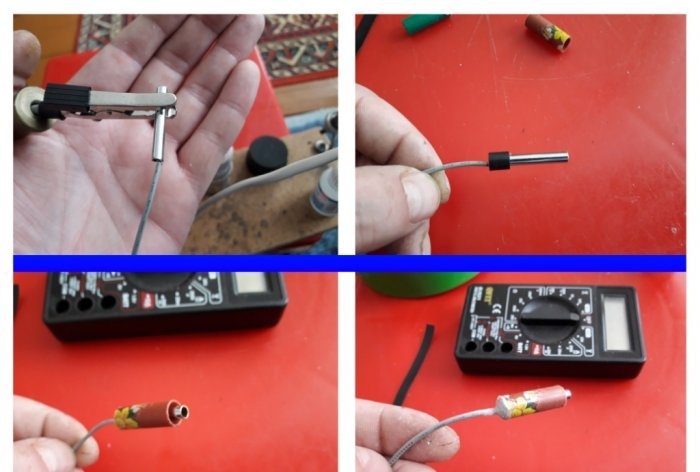

Next, take the pin from the laser CD drive and cut it in half.

Why a hairpin - it fits perfectly in its parameters, it has sharp ends and is made of excellent steel. Next, we process the sawn-off edges of the stud with flux, solder tinned wires to them at one end of each wire, put on thermal tubes, and seat them with a lighter.

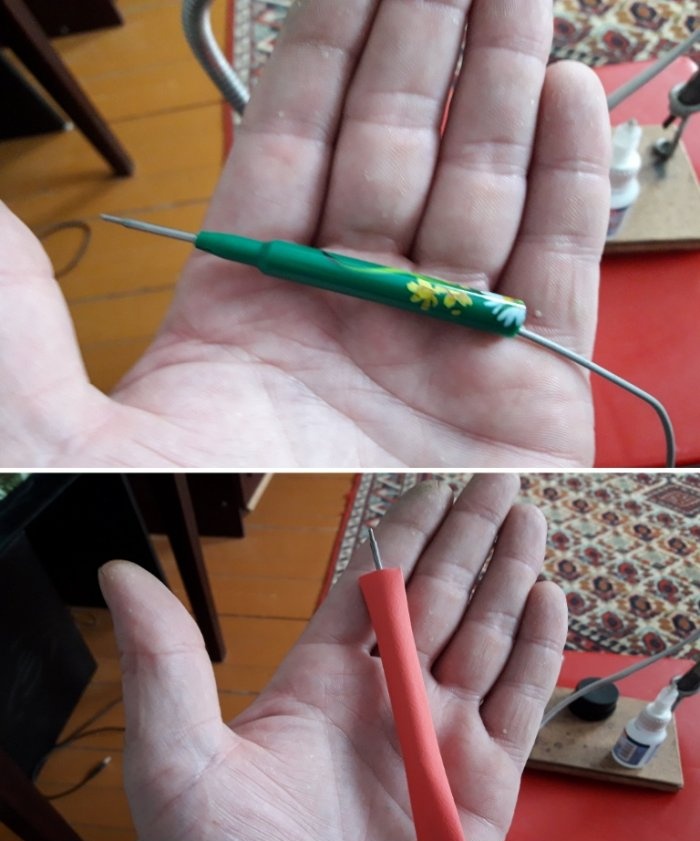

Now we cut off the upper part of the felt-tip pens, 5-7 cm. These will be the handles of the probes.

We thread the pins, with the wires soldered to them, from top to bottom, so that the pin comes out of the tip of the felt-tip pen, where the writing pen used to stick out. Add a drop of instant glue there and throw in a pinch of soda to secure it all from the inside. We thread the resulting probe handle into a red heat-shrinkable tube and seat it with a lighter. We repeat the same procedure with the second probe, only now with a black thermal tube.

Well, the upper parts of the probes are ready. All that remains is to make the plugs. For the plug, I used a brass tube from the antenna - it perfectly matches the diameter of the connector in the multimeter. We saw off 3 cm pieces from the tube.

We plug the tube into the connector. The remaining pieces from the felt-tip pens fit perfectly under the body of the plug in the connector multimeter. We insert a plastic one over the brass tube, measure it, and cut it off.

Next, we solder the remaining ends of the wires to the brass tubes, increase the diameter on them with electrical tape to fit the plastic tubes, lubricate them with second glue and insert them into the plastic tubes. You can secure everything on top with a second of glue and soda.

We cut off 4 cm of thermal tubes, red and black, put them on the corresponding plugs, and seat them with a lighter.

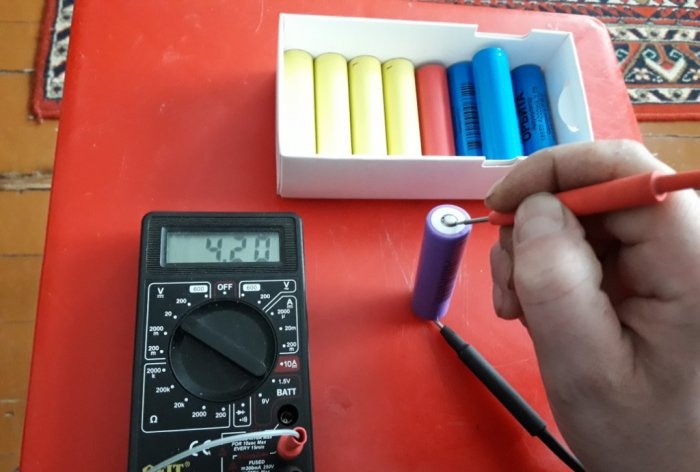

There you go. Nothing complicated. The whole job took about 40-50 minutes. Now you can try out the new probes.

The caps can be made from the braided USB cable. We put a red thermal tube on a suitable piece of braid and seat it with a lighter. We straighten with scissors. For a black probe, mono and without a heat tube, the braid itself is black.