Owners of budgetary welding inverters are faced with the problem of excessively short wires. My device has only 180 cm each, which limits the ease of use. I decided to replace the positive cable with a new solid piece, and grow the mass from 2 native segments. To connect them, I offer a reliable method without soldering and crimping.

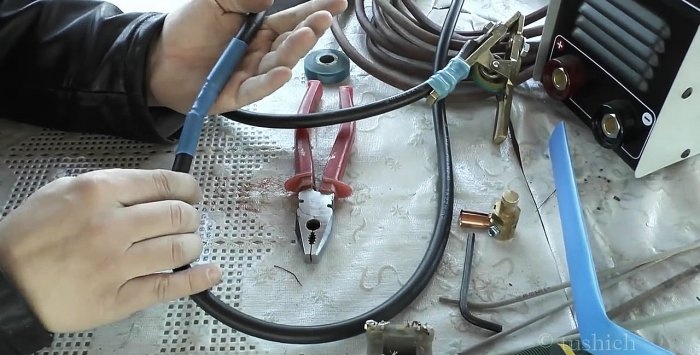

Materials and tools

To complete the work you will need:

- Allen key

- thin copper wire;

- shrink tube for cable diameter;

- insulating tape;

- pliers;

- gas soldering iron;

- scissors for metal or cable cutting;

- mounting knife.

Cable splicing

First you need to remove the cable lug that connects to the inverter. To do this, it is inserted into the apparatus, after which it is necessary to pull the insulating cap on yourself with force. Under load, he exits, opening the tip. He is fixed with one bolt. You need to unscrew it with a hex wrench to release the cable. To prevent crushing, the bundle of cores is wrapped with a copper plate, which also needs to be removed by unscrewing with pliers.

Next, you need to prepare two free ends on the cable segments for splicing. With the help of a cable cutter or scissors for metal, their ends are trimmed to make even ends.

The length of the bare wires on both cables should be the same. Depending on the situation, you will need to remove a little extra insulation on one of them with a mounting knife or just cut the second wire a little more. The optimal length of the bundles for splicing is about 3 cm.

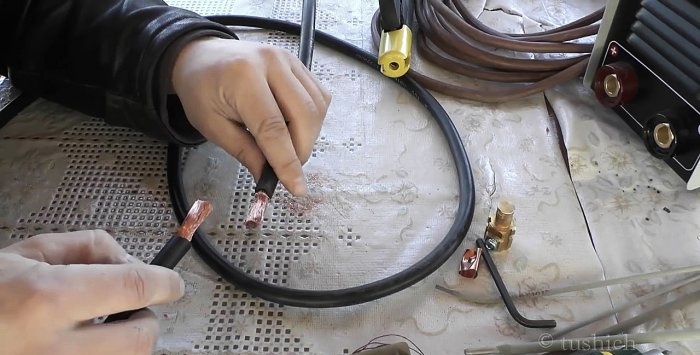

I substitute the ends of the prepared bundles of cores of two cables to each other and with massaging movements I push them towards them. Copper conductors move apart, providing splicing. As you move the copper wiring fluff up, so you need to control them with your fingers, returning to the place so that they do not refract.

After the veins reach a few millimeters before the start of insulation, they need to be squeezed with your fingers. There is no need to spin anything. In this method, twisting is not applied.

To fix the splice I take a copper wire. It can be removed from any old electric motor or transformer. It has a transparent dielectric coating, but it does not hurt. In no case should you use aluminum, since it oxidizes with copper. Steel is not suitable, due to poor flexibility.

To reliably tighten the wire, I use a fishing knot that fixes the hooks to the fishing line. For this, a long loop is formed at its end. The wire simply folds in half with a short tail of about 8 cm. It is applied to the spliced cable with a centimeter overlap on the insulation. After that, the long end begins to be wound from its short tip towards the rotation of the loop.

For greater reliability, you need to wind the coil to the coil. The wire must be tensioned to achieve a tight connection. After covering the entire length of the cable splices with coils, the wire is cut. You need to leave the tail at about 10 cm.

The resulting end is launched into the loop ring. After this, the loop is pulled over a short edge, which is located on the other side, where the coils were started.You need to tighten until the long end goes under the winding.

It remains only to isolate the finished connection. To do this, I first tightened it with a heat-shrink tube, after which I decided to add some more insulating tape. It turned out it would be better to do the opposite.

Tip installation

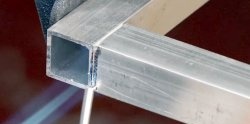

It remains only to install the cable end. You must first align the plate holding the cores in the bundle. It is aligned with pliers. After that I warm it up with a gas soldering iron red-hot and throw it into the water. The same principle applies as when hardening steel, but copper from this becomes not hard, but soft. The softened plate is easily wound around a bundle of cores.

Next, I install a tip on it, clamp the bolt with a key and return the insulating cap to its place. If he does not want to sit tight, then a little electrical tape can be wound around the cable to make a thickening.

This method of cable splicing is almost eternal, and does not require expensive rarely used tools, such as a powerful soldering iron or crimp press for sleeves. The connection is quite flexible, which is what is required of it.