Who did not feel irritation, looking for a particular wrench in the drawer of a bench or in a special box where they are usually located in a chaotic mess? It is possible not to spoil your mood, improve the culture of your work and not waste time searching for the right tool.

To do this, it is enough to acquire a suitable wooden beam, for the processing of which you will need some simple tools. All the work will take about no more than one hour. Having made this simple but effective holder for open-end wrenches, you will not swear, looking for the wrench you need at the moment.

Necessary tools

So that the work goes well and does not require too much physical effort, I propose the following set of tools (of course, they can be replaced by others, in particular, manual ones, the main thing is the high-quality performance of the corresponding operations):

- electric jigsaw;

- belt grinding machine (grinder);

- bench drilling machine;

- mechanical milling cutter;

- hand screwdriver;

- metal ruler and pencil;

- protractor ruler for holding inclined parallel lines.

Required Materials

In order for the fixture to last longer, the beam of the corresponding cross section must be made of hard wood: birch, oak, maple, ash, elm, etc. Also, two cambric or plastic inserts and two suitable screws of comparable sizes will be needed.

In principle, the holder for open-end wrenches can be soaked with oil, varnished, or simply painted with any oil paint. This will give them more strength and improve their appearance, which is also important in our aesthetic age.

Manufacturing process

We start work by sawing on an electric jigsaw with a suitable blank for the wrench holder of a suitable cross-section and length of a wooden beam or thick board.

Then we process all facets of the workpiece on a belt grinder, which is also called a grinder. For the back side of the workpiece, this is the final operation, therefore, it must be performed quite qualitatively.

Now you can start marking the wooden beam.

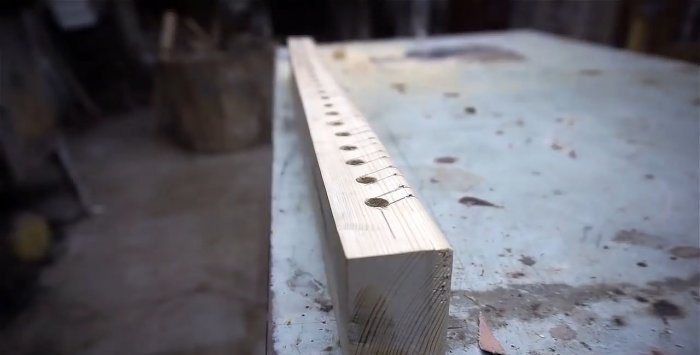

To do this, on its narrow side, using a metal ruler and a simple pencil, draw a center line along the entire length of the workpiece. Then we make marks on the drawn line every 25 mm at an equal distance. These are the drilling centers of the through holes - the lower bases of the key sockets.

We drill holes in the timber one by one, without missing a single mark, on a bench drill. The main thing in this operation is to withstand the verticality and parallelism of all holes in relation to each other.

To give aesthetics and safety to the use of a future device, we round off all face faces with a milling head of the corresponding profile, which is driven by an electric motor.

Then, using the protractor ruler, setting the required angle of inclination in advance, draw two parallel tangents to each hole along the entire length of the beam with a pencil.

Next, on an electric jigsaw, we make successive cuts to all holes along previously outlined lines and remove the resulting cubes. Spanners are ready!

It remains to drill small through holes from both ends for hinging fixtures to the wall of the garage or workshop. To do this, in pre-made holes in the wall, insert cambric or finished plastic inserts of the desired section.

It remains only to align the holes on the fixture and in the wall, and tightly screw the screws with a large head using a hand screwdriver. The device for storing open-end wrenches is ready!

It remains only to carefully insert the keys into the formed grooves in a certain sequence: large at the bottom, small at the top. As you can see, the device looks not only functional, but also quite aesthetically pleasing.

Improvements and alternatives

In principle, this key holder can simply be cut out with a small, well-sharpened, hand hacksaw, knocking out the sawn-off plates with a carpentry chisel or a flat screwdriver with a strong handle. With some accuracy, the required functionality of the product and sufficient aesthetics will be provided in the work.

Instead of a wooden bar, two metal plates can be used, interconnected from the back by welding with 2-3 jumpers. Slots can be made using a grinder.

It is simpler and more convenient for the manufacture of a key holder to use a rectangular, square and even a round pipe or a U-shaped finished profile of the appropriate size. It is possible that the reader of these lines will offer his own version of the adaptation under the keys.