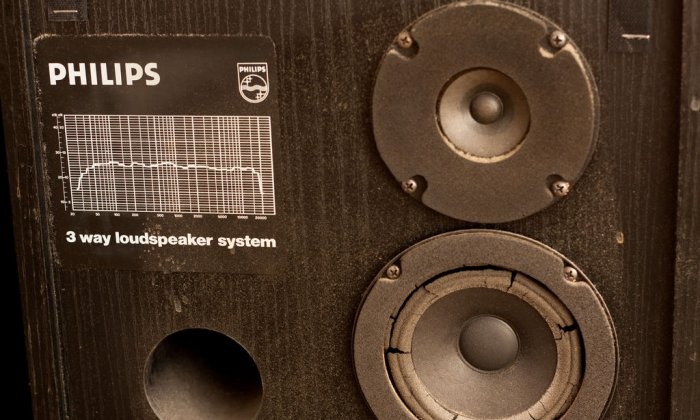

I like the old big, heavy speakers that were popular in the 90s. Despite their advanced age, they still sound pretty good and produce good bass. Recently I came across a pair of these speakers in a deplorable condition, but I decided to restore them and bring them back to life.

Professional repair of such speakers is very expensive, so working equipment is often simply thrown away and modern subwoofers that are compact in size are purchased.

Will need

For proper repair, you will need rubber or any other elastic gaskets of suitable diameter. To accurately calculate the required size of spacers, you need to measure the outer diameter of the cardboard cone and the inner diameter of the steel frame, and based on this, look for spacers of the required diameter.

Restoration work

I recorded the entire speaker repair process with a camera. Below is a detailed photo report of all steps.

The first step after removing the front panel is to remove the old seal and glue from the speaker circumference. To do this, I used a flat, sharp blade, but this must be done carefully so as not to damage the cardboard cone.

To center the cone while gluing it, you need access to the steel core. In large speakers, it is covered with a cardboard plug (it is glued), which must be carefully removed without damaging the cone. With the cardboard plugs, I managed to pry them off with a sharp knife, after which they came off along the adhesive joint, since they were not glued very tightly.

In small speakers, the dust caps turned out to be tightly glued, so they had to be carefully cut in a circle.

The next step is to accurately center the cone relative to the steel core. The free space between the cone and the core turned out to be different in each of the speakers. As an insulator and a kind of winding, I used strips of ordinary paper, which I pushed into the gap around the core until I achieved the most dense filling.

One of the small speakers required only one and a half turns of paper around the core, resulting in a slight displacement of the cone. Fortunately, in my case this circumstance did not affect the performance of the speaker, but I think that it would have been necessary to take thinner paper to complete two full turns.

For gluing rubber or foam seals, any household glue is suitable, for example, PVA or any similar one, which becomes transparent after drying. Glue is applied to the cone and speaker body along the edge of the hole, after which the gasket is carefully applied.You need to smooth it to the surface for a tighter fit and remove excess glue so as not to disturb the centering.

Once the glue has completely dried, you can remove the paper cup wrapped around the core. To check that the cone is properly balanced, lightly press it with your hand: it should vibrate freely without touching the steel core. If friction is present, all centering work should be redone and a new seal should be glued.

Now you need to install new damper pads around the speakers so that the front panel does not press or contact them. By the way, you can use old gaskets, completely free of glue, if they are in normal (not deformed) condition. The damper pad is glued to any glue. If the inner diameter of the new gasket is slightly smaller and covers the rubber seal (this can create interference), then it needs to be trimmed a little along the inner circumference so that the cone vibrates freely.

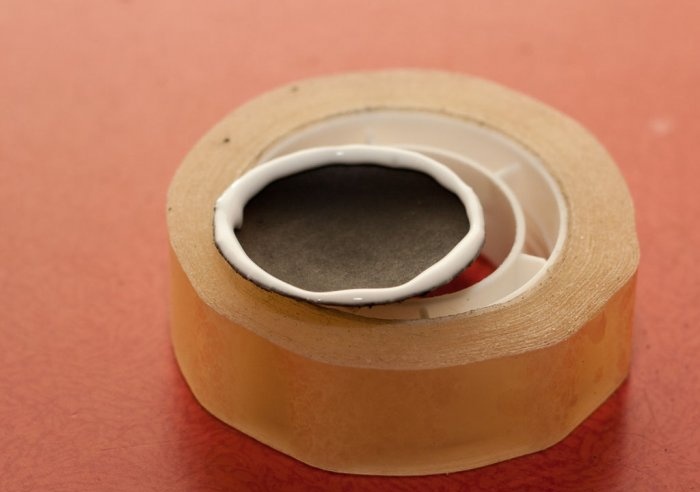

To glue the dust caps in place, I did the following:

- I glued a narrow and folded strip of tape to each cap. The result is a convenient loop so that you can move the semicircular part.

- I smeared the edges of the cap with glue.

- Carefully placed the cap in its place and applied a little pressure until the glue set.

When I put the glue-coated cap in place, the glue did not come out evenly: there were gaps in some places. To fill the voids, I ran glue around the cap to create a neat, even, and complete seam.

When the glue is completely dry, the loops of folded tape are carefully removed, after which the front panel is put in place.

Launching speakers

Now the exciting moment has come - connecting and launching the speakers. After connecting the speakers to my stereo and turning them on, I was disappointed because the sound was terrible. But after thinking a little, I came to the conclusion that this was due to the new seals, which turned out to be more rigid than necessary. So I left the speakers turned on, and after about an hour, when all the new elements I had introduced into the design of the speakers “got used to”, the sound began to improve, and I was able to enjoy my favorite music.

Original article in English