Standard Ways to Prevent Unscrewing a Threaded Joint

There are several practice-proven ways to protect threads from unwinding:

- Screwing a lock nut, which can be used as a regular nut, or a special clamping nut designed for this purpose.

- Using a spring washer.

- Application of a compound - special glue on a threaded connection.

- Use of a self-locking nut with a nylon or polyamide locking ring.

But there are situations when you need to make a non-twisting connection, but there is no suitable product, or there is no place for a lock nut on the bolt. You can do the following.

Life hack

To make a self-locking nut you will need the following materials:

- Actually, the bolt and nut to be locked.

- Electrical shrink sleeve.

- Heat source (an ordinary lighter is suitable).

- Spanners.

Technology

The essence of life hack is as follows:

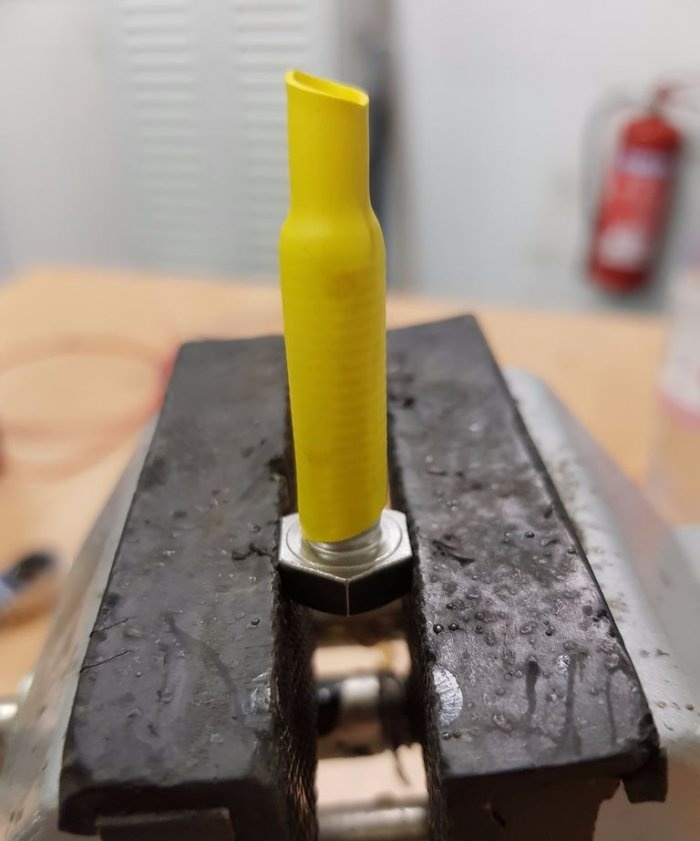

- We put a heat-shrink tube on a bolt with a small “tail”.

- We heat it so that it is compressed and tightly grasped the thread, the “tail” should remain: it will be the guide for the nut.

- We put the nut on the tube and begin to tighten. It should go very tight, so you need to use the keys from the first turn.

- The thread will cut the “tail” of the tube and it will fall off.

When the nut goes through the bolt, the tube material fills the thread, so the effect is the same as when using a nut with a pressed nylon ring.

Tests have shown that the nut sits securely and does not loosen when vibrated. If it is necessary to untwist the connection, this is done in the usual manner using a wrench and the necessary effort.

Note! This method is valid for bolts with a diameter of at least M8, since with a smaller diameter of the heat shrink tube it does not provide sufficient force to ensure reliable fixation.

We hope that this simple, quick and convenient way to fix a threaded connection will be appreciated by home craftsmen.