Hello! Today I will show how to get 220 V from a regular single-phase network - a three-phase one, and without any special expenses. But first, I’ll talk about my problem prior to the search for such a solution.

I had a Soviet powerful desktop circular saw (2 kW), which was connected to a three-phase network. My attempts to power it from a single-phase network, as is usually accepted, did not seem possible: there was a strong power drawdown, starting capacitors were warming up, the engine itself was warming up.

Fortunately, in due time I spent the proper time searching for a solution on the Internet. Where I came across one video, where one guy made a kind of splitter using a powerful electric motor. Then he launched this three-phase network along the perimeter of his garage and connected to it all other devices requiring a three-phase voltage. Before starting work, he came to the garage, started the distribution engine, and before leaving he worked. In principle, I liked the solution.

I decided to repeat and make my splitter. In the role of the engine, he took the old Soviet at 3.5 kW of power, with windings turned on by a star.

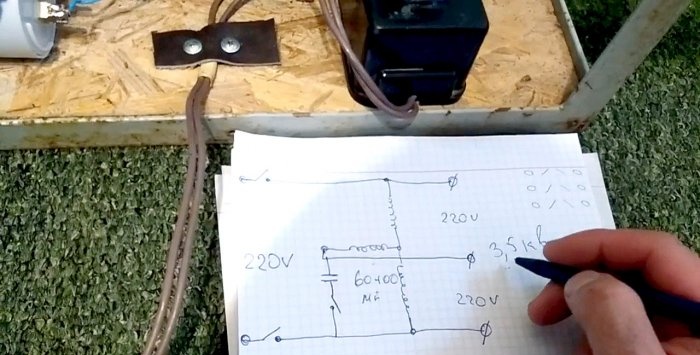

Scheme

The whole circuit consists of only a few elements: a common power switch, a button for starting, a 100 microfarad capacitor and a powerful motor proper.

How does it work? First, we supply single-phase power to the distribution motor, using the start button we connect the capacitor, thereby starting it. Once the engine has spun to the desired speed, the capacitor can be turned off. Now you can connect the load to the output of the phase splitter, in my case a desktop circular and a few more three-phase loads.

Device body - the frame is made of L-shaped corners, all equipment is fixed on a piece of OSB sheet. Handles for carrying the entire structure have been redone from above, and a three-pin outlet connected to the output.

After connecting the saw through such a device, a significant improvement in work was obtained, nothing is heated, power is quite enough, and not only for the saw. No growls, no buzzing, as it was before.

It is only advisable to take the distribution motor more powerful than consumers by at least 1 kW, then there will be no noticeable special drawdown in power under a sharp load.

Whoever says anything about a not pure sine or it does not give anything, I advise you not to listen to them. The sine of the voltage is clean and broken exactly 120 degrees, as a result, the connected equipment receives high-quality voltage, which is why it does not heat up.

The second half of readers who will speak about the 21st century and the great availability of frequency converters of three-phase voltage can say that my output is several times cheaper, since the old motor is quite simple to find. You can even take unfit for the load, with weak and almost broken bearings.

My idle phase splitter does not consume as much: 200 - 400 W somewhere, the power of the connected tools grows significantly, compared to the usual connection scheme via starting capacitors.

In conclusion, I want to justify my choice of this solution: reliability, incredible simplicity, low costs, high power.