It's no secret that instant glue + soda is a reliable and durable bonding of surfaces. It doesn’t matter which ones, not necessarily even homogeneous ones. Plastics + iron, plastics + glass, iron + glass... I can go on and on! The only important rule is that the surfaces are not wet or greasy. But there is a solvent for these purposes. Let's say; if we are gluing wood and, for example, plastics, and the wood is wet, it is not necessary to wait until it dries - this is a rather long process! You just need to generously moisten the desired area of wood with solvent. The solvent will mix very quickly with the water in the wood and dry almost immediately along with the moisture.

At least from the top layer, which we need for connection. Now we will consider several options for connecting different and homogeneous surfaces. No tools are needed to work. With the exception, perhaps, of sandpaper, in case a sloppy connection suddenly occurs and you need to remove the mixture of glue and soda that has seized in the wrong place. So, let's begin.

Will need

- Secondary glue.

- Soda.

- Bonded surfaces

- Sandpaper (just in case!).

We glue two surfaces tightly

First, let's glue two homogeneous surfaces. In my case it was a cracked freezer compartment.

At first I tried to solder it with a wood burner, but after some time it burst again in the same places. Now, I'm sure the fastening will be more reliable. We will glue it from the outside so that the glue does not come into contact with the products. So, using instant glue, we will attach the surfaces to be glued so that they do not play during the main work.

Now that the surface is fixed and does not move, apply a layer of glue to the crack. There is no need to fuss or rush: although the glue is instant, it may not dry out for a long time until it comes into contact with something. After we have applied the glue, we sprinkle baking soda on the crack.

We wait a couple of seconds and blow off the remaining soda. We repeat the procedure over the new seam to secure the result. And now we have a reliable connection!

Now let's glue two homogeneous parts from the inside. Previously, while modeling and making mock-ups (small copies of something), I was always faced with the problem of a flawless appearance of the model - how to glue it together so that the seams were not visible. At first I used cold welding, but it took a very long time to dry. And if the massive surfaces to be glued have an area of only a couple of millimeters, superglue alone will not be enough for a reliable connection. Eg; I built a model of a cruise missile.

Its base consists of a metal-plastic tube with a diameter of 16 mm.How to glue two pieces of tube so that there are no seams sticking out from the outside? There will be no problems when gluing identical tubes - you can simply take a cylinder of the required diameter and place both parts of the tube on it, having previously lubricated them with glue.

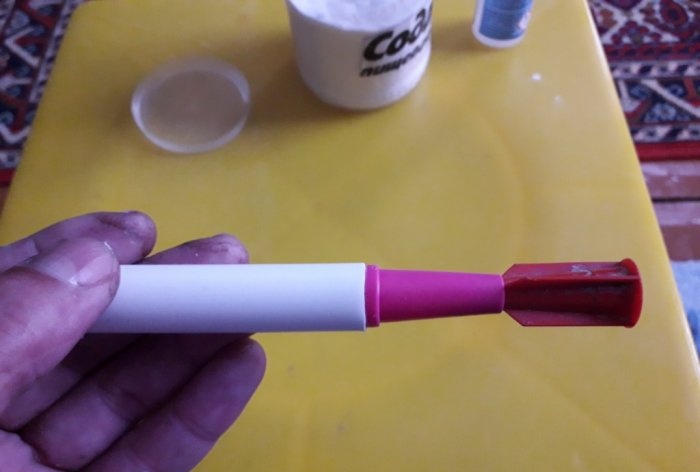

However, gluing the shank to the rocket, which has a much smaller diameter and also gradually expands towards the end (the bell, which turned out to be a cap from a similar glue), turned out to be even easier; just insert the bell cone into the tube, drip 10-15 drops of glue from the other end of the tube and pour soda into it.

That's all! After a couple of seconds, pour out the remaining soda. I can’t think of a more reliable fastening!

Now let's connect the tree. For my favorite indoor pepper, I put together a small decoration (also a kind of model!) made of wood: two slingshots, a crossbar and a pot.

When assembling the “bonfire” model, soda and glue again helped me out. Having cut miniature logs, I wiped them with solvent to remove the remaining moisture from the wood and, one log at a time, placing them on top of each other, dripped glue and then sprinkled them with soda.

Despite the fact that this entire structure is constantly exposed to water, when watering a plant, the tree will rot rather than the joint disintegrate!

It will be a little more difficult to connect the plastic from the bottle with the same plastic, or something foreign. The plastic from the bottle has a very smooth surface. In addition, it is unusually flexible. Sandpaper will help out here. With its help, we simply clean the surface of the plastic, making it rough.

Thanks to microscratches, the bonded surfaces will firmly adhere to each other. And in order to avoid possible lag along the edges of these surfaces, again, we dig glue along their perimeter and immediately cover it with soda.

Now let's glue the metal and rubber together.Having spared money and bought a cheap Chinese selfie stick, my daughter asked me to somehow attach the rubber handle (which constantly moved along the entire length of the stick as if it were alive!) on the metal base of the stick. In essence, this handle is a flexible rubber tube stretched over a metal base.

Without thinking twice, I resorted to the already favorite gluing method - I applied glue to the place where the rubber came into contact with the metal and repeated the procedure with soda.

In general, you can continue as long as you like, you can’t list everything. The main thing is to remember the basic principles of this gluing method: first, superglue does not tolerate moisture and grease when gluing, and second, if the working surface is very smooth; We use sandpaper.