What is better to drill red-hot steel? - The question that masters are asked when such a need arises. For example, there was a need to check a red-hot steel blade ... I will show you how I personally do it and which drills I use.

Making a homemade drill

Hard-alloy rods, tungsten-cobalt rods will be needed, the people will win.

But in fact, this will not defeat this VK8.

Clamp in a manual vise.

And we make a drill from the rod, grinding off the excess. It’s very difficult to grind hard alloys on a usual grindstone, I use diamond.

We sharpen two planes, like a flat screwdriver.

We process the second facet.

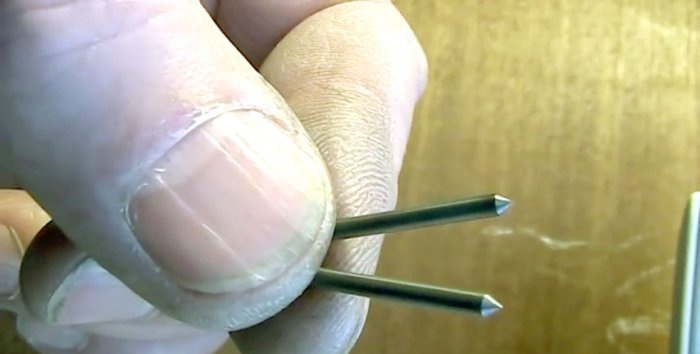

It turned out just such a feather. Now sharpen the cutting edges.

The result was a drill for hot metals.

Homemade drills are ready. It is necessary to make several of them at once, since they are quickly dull and you will not be able to sharpen them each time.

Of course, you could use ordinary, carbide drills, but still had to grind them, and why redo it when you can do your own.

Drill a hole in red-hot steel

We will drill a hot saw from a quick cut.

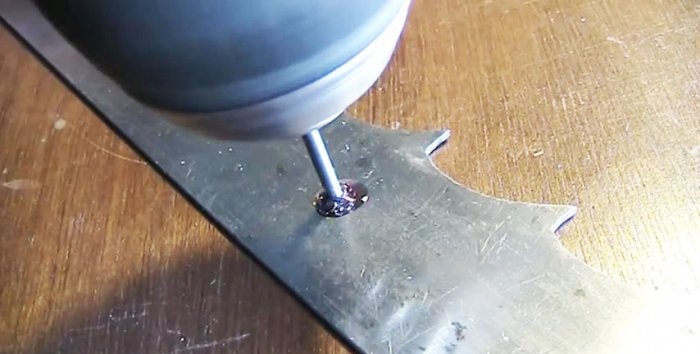

We drip a drop of oil and start drilling at low speeds. It is not necessary to punch, with such a sharpening, the drill does not slip on the metal.

We change the cutting part.

Half a minute and a hole in the hot steel was drilled.

Let's complicate our experiment and take a stronger, harder, high-speed steel CSX.

Again, drip a drop of oil. We drill for five seconds and the cutting edge is dull, so we need to take another drill, which I did. Each time I take a different drill.

Carbide is very brittle and crumbles very often at the exit. Just some two minutes and a hole in the hardened steel was made.

Thank you all for your attention!