The basis was an industrial asynchronous AC motor with a power of 1.5 kW and a shaft speed of 960 rpm. By itself, such a motor cannot initially work as a generator. It needs improvement, namely replacement or modification of the rotor.

Engine identification plate:

The good thing about the engine is that it has seals everywhere it needs to be, especially at the bearings. This significantly increases the interval between periodic maintenance, since dust and dirt cannot easily get anywhere and penetrate.

The lamps of this electric motor can be placed on either side, which is very convenient.

Converting an asynchronous motor into a generator

Remove the covers and remove the rotor.

The stator windings remain original, the motor is not rewound, everything remains as is, without changes.

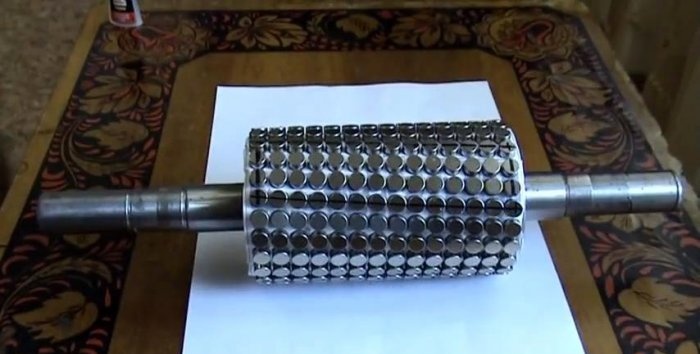

The rotor was modified to order. It was decided to make it not all-metal, but prefabricated.

That is, the original rotor is ground down to a certain size.

A steel cup is turned out and pressed onto the rotor. The scan thickness in my case is 5 mm.

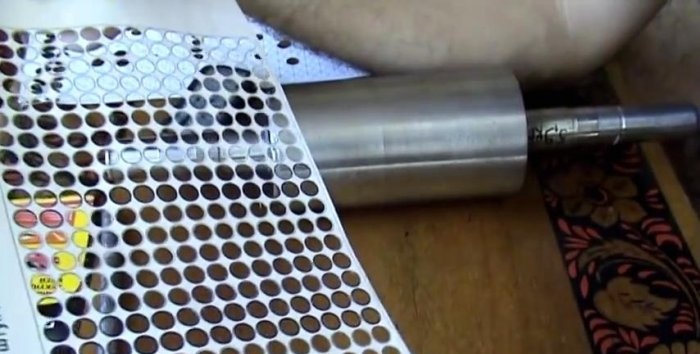

Marking the places for gluing the magnets was one of the most difficult operations.As a result, through trial and error, it was decided to print the template on paper, cut out circles in it for neodymium magnets - they are round. And glue the magnets according to the template onto the rotor.

The main snag arose in cutting out multiple circles in the paper.

All sizes are selected individually for each engine. It is impossible to give any general dimensions for the placement of magnets.

Neodymium magnets are glued with super glue.

A mesh of nylon thread was made for strengthening.

Next, everything is wrapped with tape, a sealed formwork is made from below, sealed with plasticine, and a filling funnel is made from the same tape on top. Everything is filled with epoxy resin.

The resin slowly flows down from top to bottom.

After the epoxy resin has hardened, remove the tape.

Now everything is ready to assemble the generator.

We drive the rotor into the stator. This must be done with extreme caution, since neodymium magnets have enormous strength and the rotor literally flies into the stator.

Assemble and close the lids.

The magnets don't touch. There is almost no sticking, it turns relatively easily.

Checking the work. We rotate the generator from a drill, with a rotation speed of 1300 rpm.

The engine is connected in a star; generators of this type cannot be connected in a triangle; they will not work.

The voltage is removed to check between phases.

The asynchronous motor generator works great.

Watch the video

For more information, watch the video.

Author's channel - Peter Dmitriev