An easy and quick way to solder two different conductors I will show on the example of a copper wire with a diameter of 2 mm, a copper plate, an ordinary metal nail. The problem of soldering such conductors is the difficulty of uniform heating of the contact point. Using a household soldering iron is almost impossible to ensure high-quality soldering, so we will not use this tool. The method is based on the use of a simple burner made of cheap materials that can be purchased in ordinary stores.

To make a compact burner, we need:

- Cheap lighter with flint and wheel.

- The plastic core of the gel pen.

- Syringe needle.

- Glue thermal gun.

- Super glue.

- Soda, which is used in baking.

Burner preparation

Disassemble the gel pen, remove the core, remove the metal writing element from it, and dispose of the ink. You should have a clean plastic tube in your hands. You can replace it with any plastic tube of the same diameter.

For convenience, I recommend bending the plastic tube at a right angle. Bring it to the flame of the lighter for a few seconds and gently bend in the middle.

Take the lighter. Using pliers, remove the metal shield, remove the wheel, silicon, and feed spring. Be careful not to damage the plastic gas supply lever. We need it to control the burner fire.

Gas burner assembly

Take a regular syringe needle. Do not throw out the cap, as it is useful when storing the burner. Use a hot glue gun to connect one end of the plastic tube to the needle. Check for tightness and tightness.

To connect the opposite end of the tube and the lighter, soda and superglue are required. The tube must be secured to the plastic arm with which the gas valve opens. The tube must be fixed in such a way that the lever can move freely within the limits set by the manufacturer to start and stop the gas supply. Gently sprinkle the place of attachment with soda and apply super glue on top. Test the operation of the compact, gas burner by pressing the gas valve and holding the spark to the sharp end of the needle.

The quick solder tool is now ready.

Examples of soldering two conductors

For high-quality soldering of the place of twisting of copper cables, we will use solder, rosin with alcohol and a manufactured burner.

Quick soldering process:

- The place of twisting must be cleaned and treated with a solution of rosin with alcohol.

- We wrap a piece of solder made in the form of a thin wire at the junction.

- We ignite the compact burner and bring the flame to the junction of the conductors.

- We are waiting for uniform heating of the material and complete melting of the solder.

- Let’s wait until the solder cools down. To remove traces of soot, wipe the place of soldering with a rag moistened with alcohol.

- Check the quality of the connection.

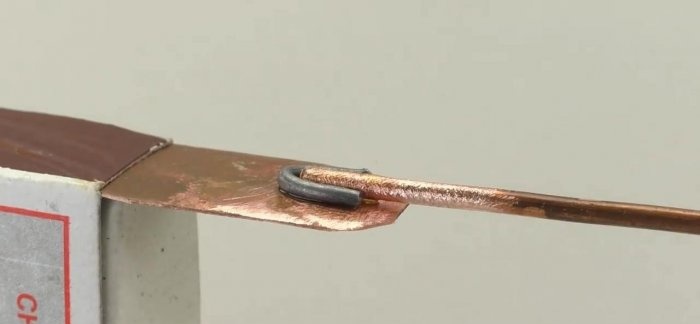

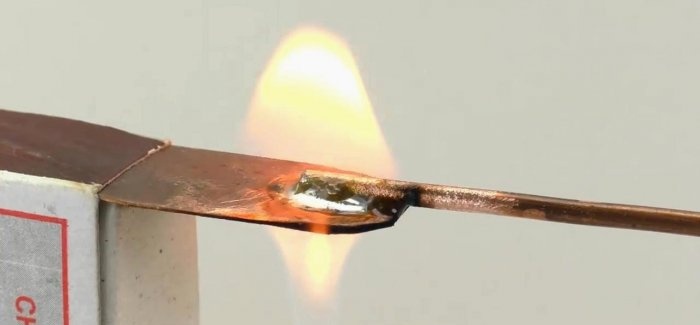

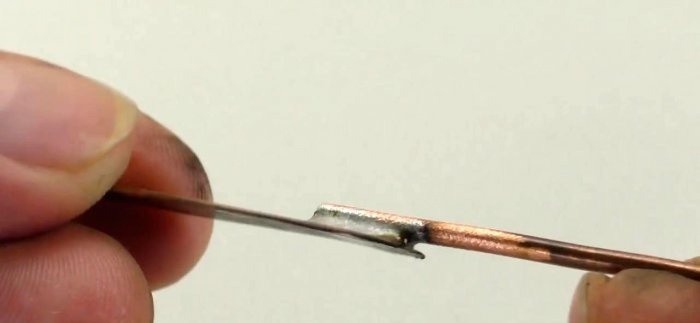

Combining Copper Plate with Copper Wire

We act in a similar way. We fix the conductors in a position convenient for soldering. We process the junction with a solution of rosin and alcohol. We lay a small piece of solder as close to the copper wire as possible. We take the burner and heat the contact point until the solder is completely melted.If necessary, add the right amount of fixing material.

Soldering different metals

We will test the method using the example of a metal nail and a piece of copper wire. A stripped, copper cable is wrapped around a metal nail. We process rosin with alcohol. Between the turns of copper wire we wind the solder. We bring the flame of the burner to the junction and heat the material until the solder is completely melted. To remove traces of burning, use a rag dipped in alcohol.