The advantage of this tool is accurate and safe cutting at right or specified angles. The engine is most often located above the frame, and is mounted on a movable carriage with a handle. The cutting depth is set by limiters at the base, and by hand. Power tools of this kind have already been appreciated by many professional craftsmen and novice amateurs. We invite you to do this too!

The advantage of homemade trimming

Today, no one is surprised by a miter saw. A lot of modifications, from branded ones to cheap Chinese ones, with longitudinal and angular cuts are present on the market. However, their cost sometimes goes through the roof, and the accuracy does not always correspond to the declared one. Is it possible to do without purchasing a specialized tool, you ask.

Our proposed installation proves that a rip-cut miter saw can be made at home. The costs of its assembly are minimal.In addition, the drill on which our trim is made can also be used for its intended purpose.

Required materials and tools

Consumables:

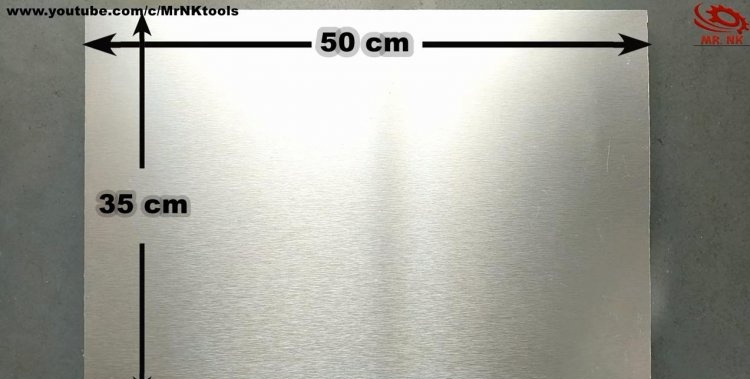

- For the frame: a sheet of plywood 14-20 mm thick, galvanized on one plane;

- Cutting disc with Pobedit tips for longitudinal cutting, diameter – 125 mm;

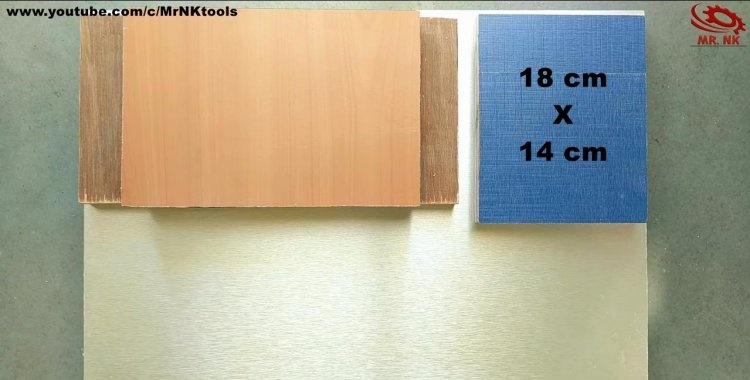

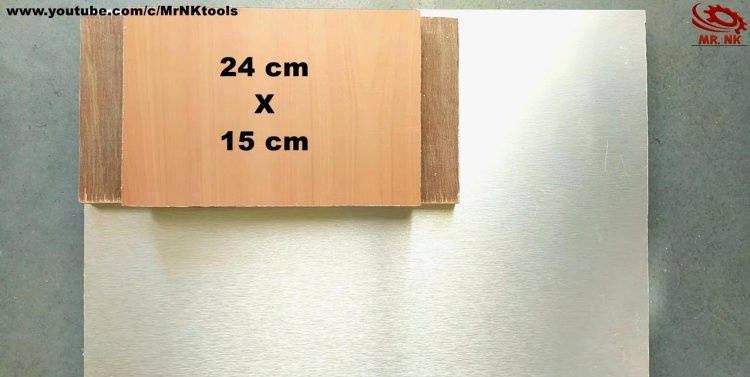

- Three pieces of plywood: 30x15 cm - for the handle, 24x15 cm - for the carriage, 18x14 - for the base stand;

- One-piece window hinge - 1 piece;

- Drill (possible without reverse);

- Two pairs of U-shaped detachable guides for furniture drawers;

- Hardware: bolts, nuts, screws;

- Cardboard for template;

- Wood glue, wood varnish.

Tools:

- Drill or screwdriver;

- Jigsaw with wood saw;

- Pliers, drills, nozzles for tightening screws;

- Painting knife, tape measure, pencil, brush for varnish and glue.

Let's get started

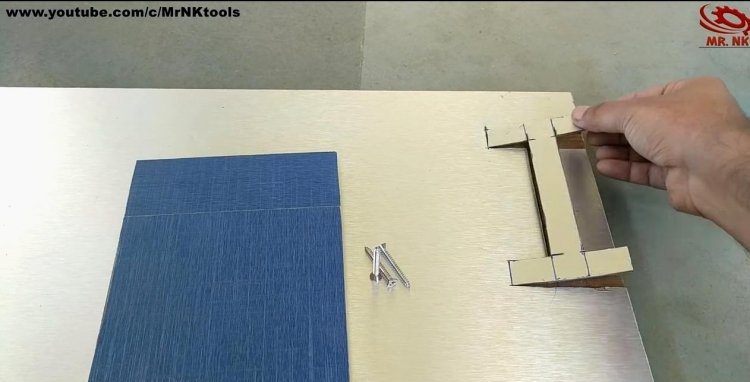

1. Secure the base stand

We mark the position of the base post on the frame, shifting it to the left side from the middle, and cut the galvanized sheet under it with a chisel.

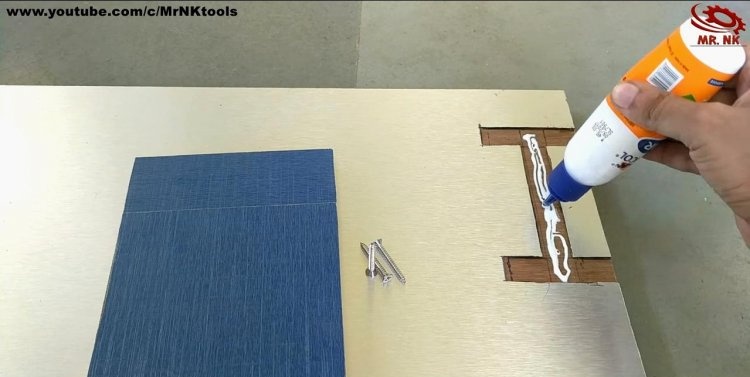

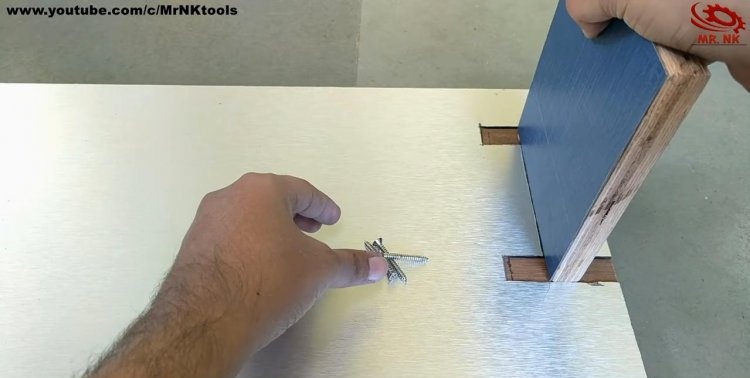

We take a piece of 18x14 plywood and screw it vertically onto 3 self-tapping screws, having previously glued the connection to the frame.

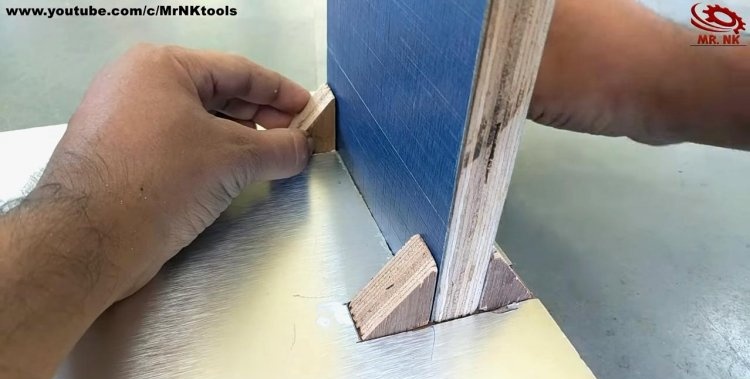

For more stability, you can add several stops in the form of corners from the same plywood. We glue them on both sides of our stand.

2. Making a handle

Using a template prepared in advance, we mark the handle of our cross-cutting tool. We use a piece of plywood 30x15cm.

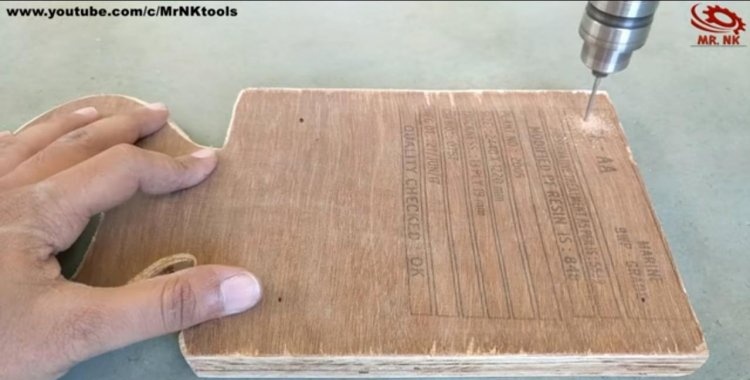

It is convenient to cut curved lines with a jigsaw. The closed contour must first be drilled with an 8-9mm drill to match the width of the jigsaw file.

After cutting, we process the edge of the plywood with a rasp or sandpaper, and make the handle streamlined and without burrs.

3. Connect the handle to the carriage

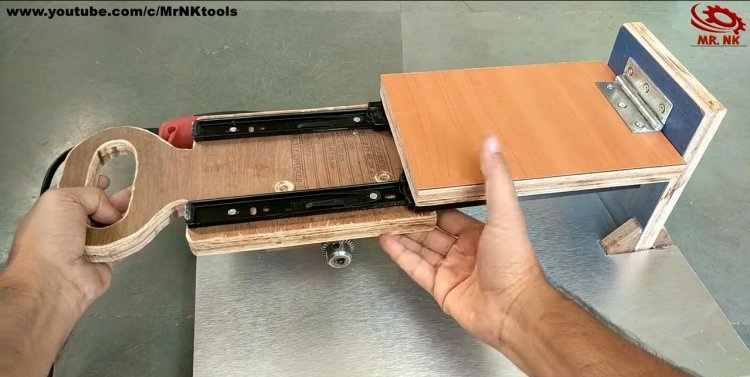

For this we need furniture guides.

We attach one of their parts to the sides of the handle, the second to the carriage.

Both pairs of guides must coincide so that the frame and the handle are practically in the same plane, and ensure free movement of the handle without any jamming.

4. Secure the drill

From the back of the carriage we attach the drill holder to the screws. It can be made from a small piece of plywood by making a sufficient hole for the cartridge.

We press the drill with a cuff made of a galvanized plate, pulling it onto the handle with self-tapping screws.

5. Install the carriage

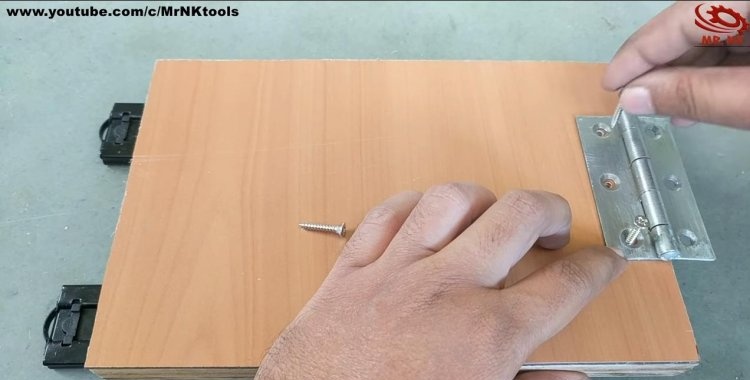

For a more convenient arrangement of workpieces on the bed and trimming them, it is necessary that our carriage has a vertical stroke. This condition will be provided to us by the window hinge.

We screw it with self-tapping screws onto the edge of the carriage and to the base so that the moving part can rise and fall to a right angle position. In this case, the carriage will act as a stopper and will not allow the cutting disk to drop below the specified level.

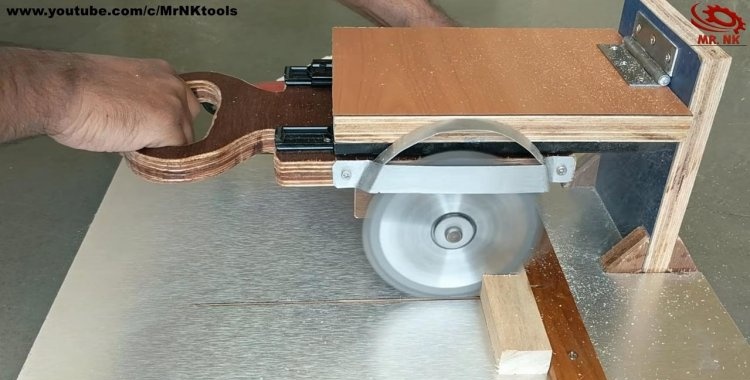

6. The final stage of work - install the cutting disc, protective cover and limit bar

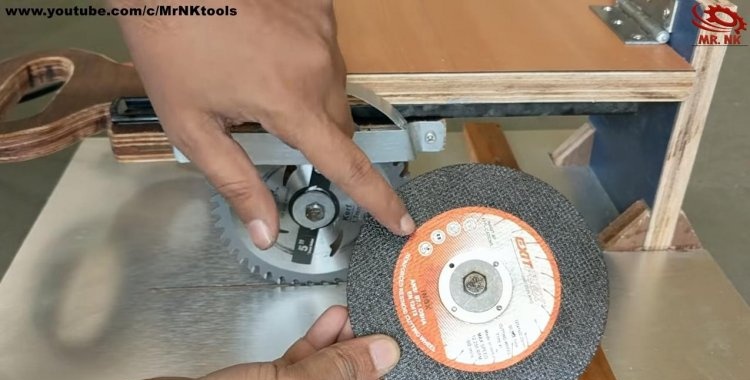

Using an M8 bolt, 50-60mm long, we make a shaft for our trimming machine. For the disk, it is best to choose wider washers, because the mounting hole for cutting disks of this diameter can be 15-20mm.

We tighten the disk on our shaft with a locknut and clamp it in the drill chuck with a wrench.

We place the protective cover above the cutting disc and also attach it to the screws. It should be made from a plate more than 1mm thick.

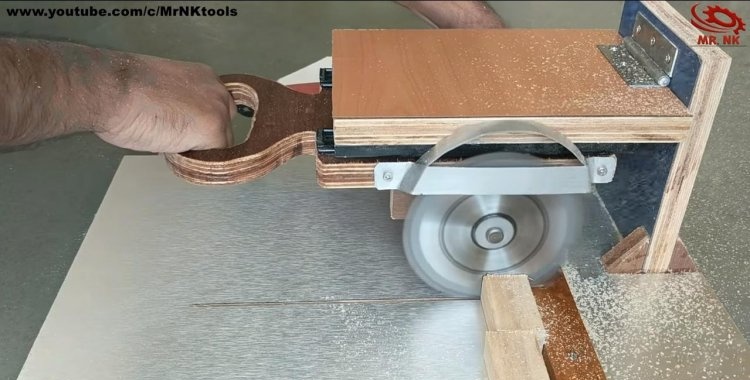

We do a test run of our miter saw and check its longitudinal stroke. The cutting disc should go literally a few millimeters into the bed.

We roll the furrow with the cutting disc to the limit.At the very edge of the cut mark, we place a limiting strip made of plywood or wood perpendicularly.

For ease of use, you can varnish the handle with regular quick-drying varnish.

Work on machines of this kind must be carried out in plastic glasses. This will protect your eyes from dust, shavings and even hot corundum.

We carry out tests with narrow and wide parts. If you wish, you can try replacing the cutting disc for wood with a cutting disc for metal, and try cutting some small rolled metal, for example, a plate or pipe.

As you have already seen, the necessary equipment can be made even from inexpensive inexpensive elements. In a small workshop it can help out at the right time, and in field conditions it will become a real help to a true master of his craft.