Video instructions for making a circular saw

This article is intended for those who are interested in how to make a circular saw themselves. This saw can be powered by a 12V motor, so you can power it from rechargeable batteries. You can take it and connect it in your car. A saw is used to cut boards. The motor you choose must have more power - only in this case the work will be definitely effective.

What materials and tools are needed?

The following materials are used to carry out the work:

- - 12-Volt motor;

- - rechargeable batteries 12 V;

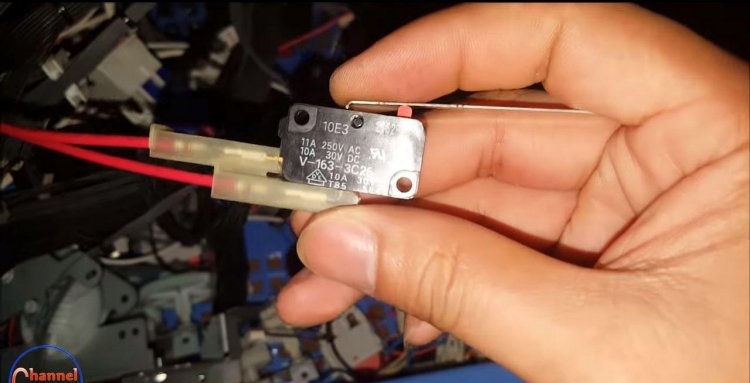

- - switch;

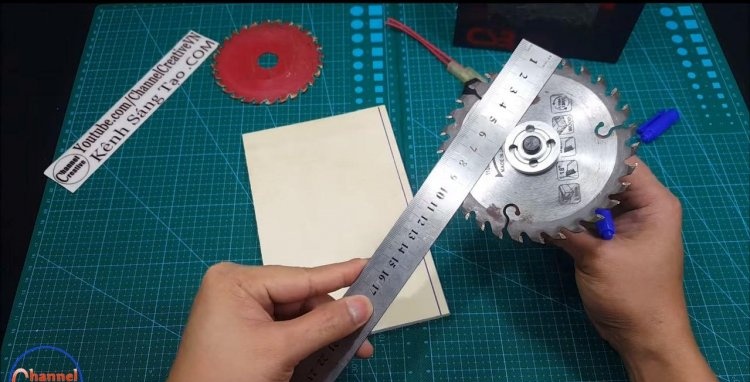

- - cutting disc 110 by 20 mm;

- - adapter for the motor (with which you can install disks);

- - sheet plastic or other;

- - small screws, self-tapping screws;

- - epoxy adhesive;

- - clamps made of metal;

- - plugs for plastic pipes;

- - two corners of plastic pipes (27) and a piece of pipe (used as material from which the handle can be made);

- - a piece of plastic pipe used to create a protective casing;

- - block with contacts;

- - heat shrinkage;

- - dye.

There is also a need to use the following tools:

- - hacksaws for metal;

- - glue gun;

- - drills;

- - soldering device;

- - marker;

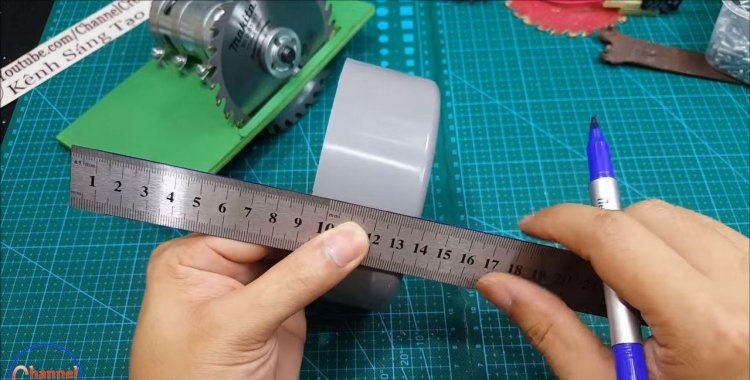

- - rulers;

- - rivet gun;

- - screwdrivers;

- - "dremel" (recommended).

The circular saw is made in the following ten steps.

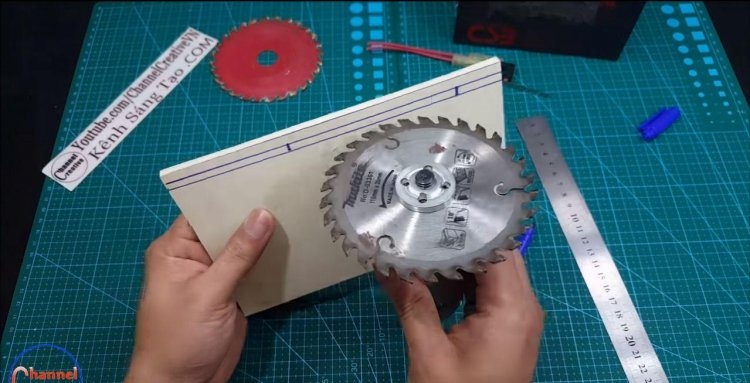

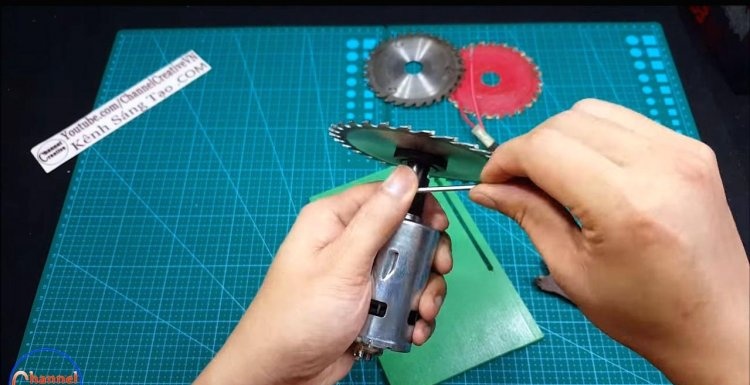

Installing the cutting disc

Using a special adapter (disc adapter), you need to attach the cutting disc to the motor shaft. Today such an adapter can be easily found in many specialized stores. Having tightened the screws securely, install the adapter, and then install the disk: its fastening is done in the same way as it is done on an angle grinder. The disk should not unscrew during operation, so tighten all existing knots well.

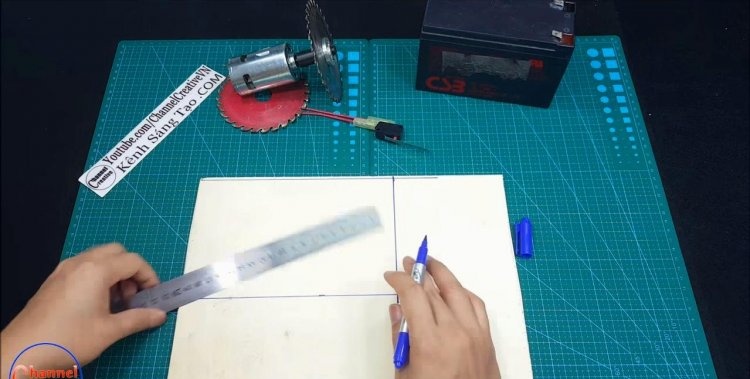

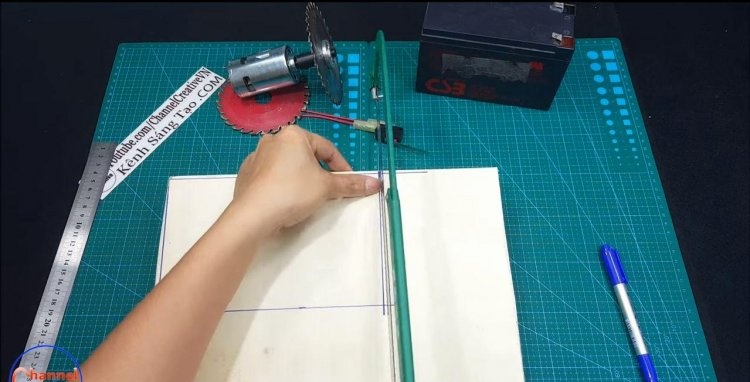

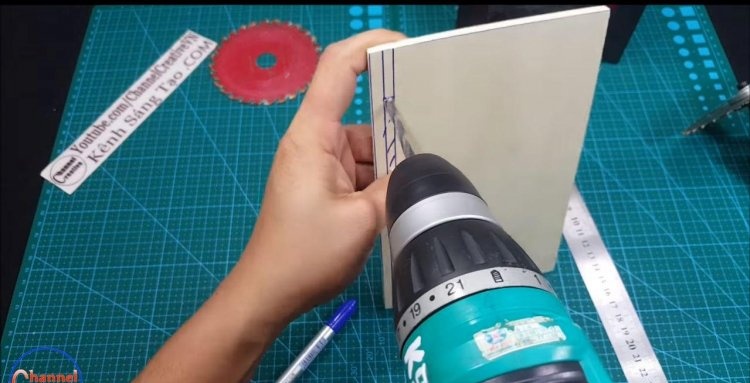

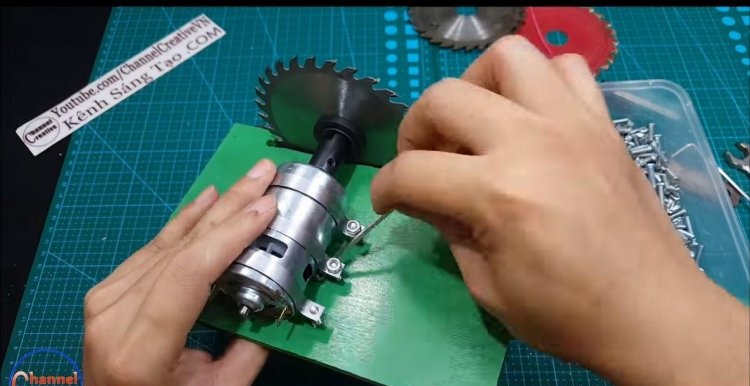

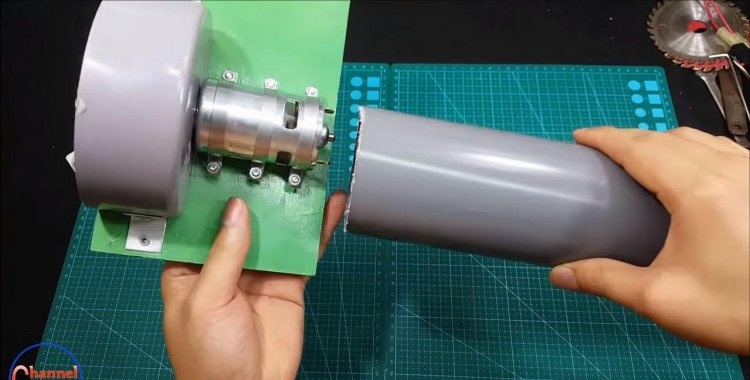

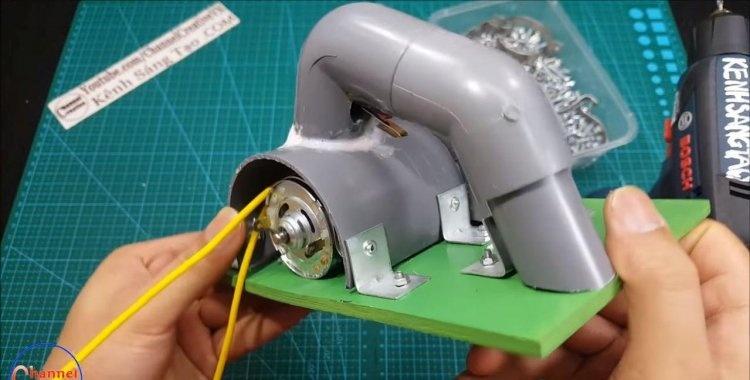

Installing the engine on the base

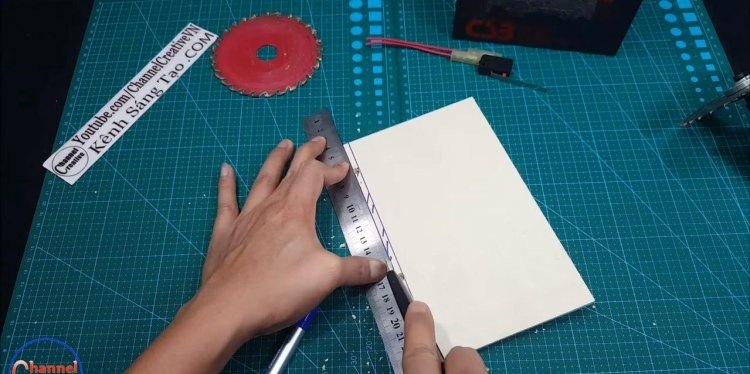

First of all, find some plywood or other durable material with which to make the base. Cut out the required piece and draw the corresponding lines. Next, using a stationery knife, you need to cut out the window, and then drill holes in the material.

Then, using several clamps, screws with nuts and washers, you can attach the motor. To prevent the motor from “walking” on the base, tighten the nuts securely. Next, you need to make sure that the rotating disk does not touch the base.

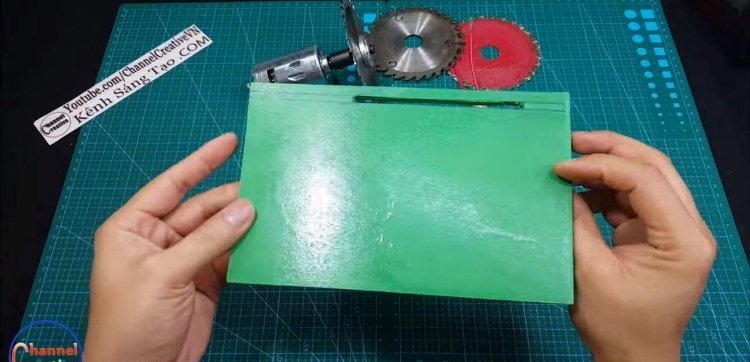

Before assembly, the base can, for example, be spray-painted green. It is necessary to drill holes for the screw heads, and in such a way that they do not have to be ground down.

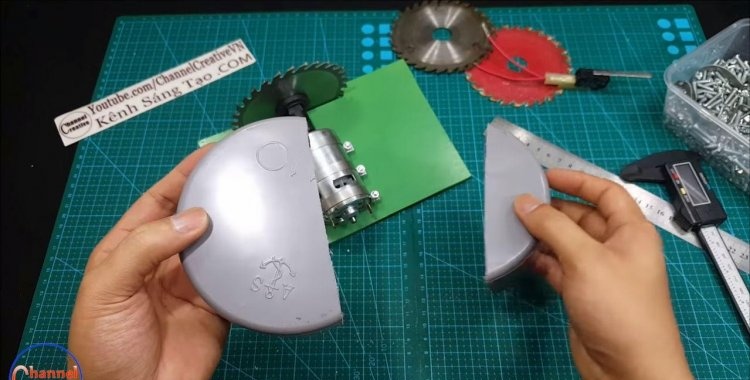

Manufacturing and installation of a protective wing

During operation, chips should not fly to the sides, so for such a device it is necessary to install a protective shield. You can make a protective shield from a plug for plastic pipes size 110. You need to take measurements and cut off the excess part from the plug using a metal hacksaw. Also, cut a groove for the motor shaft.

After making the wing, you can begin to install it. This can be done using aluminum corners, as well as a rivet gun. You should drill holes of the required diameter and install rivets on the wing, placing washers on the other side. It is recommended to use rivets for assembly.

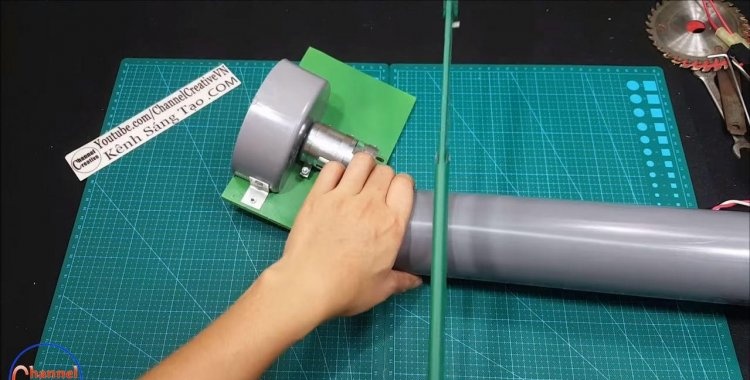

Special casing to protect the motor

The motor must also be closed, because it needs to be protected from dust particles, in addition, it can overheat. The casing is made from a piece of plastic pipe of the appropriate diameter. Using a hacksaw for metal, you need to cut it lengthwise, and then secure the casing with corners made of aluminum. The corners are secured to the casing with rivets, and the housing is fastened to the base using screws and nuts - this is necessary to be able to remove the casing and have access to the motor.

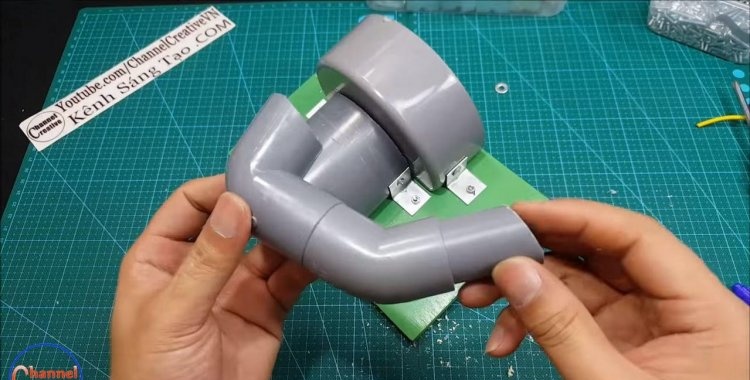

Making a pen

To operate the device safely, you must have a comfortable and reliable handle. It can be made using two connecting angles for pipes and two small pipes.You need to cut everything to the required size at the required angle, and then assemble it with glue.

Now you have a pen!

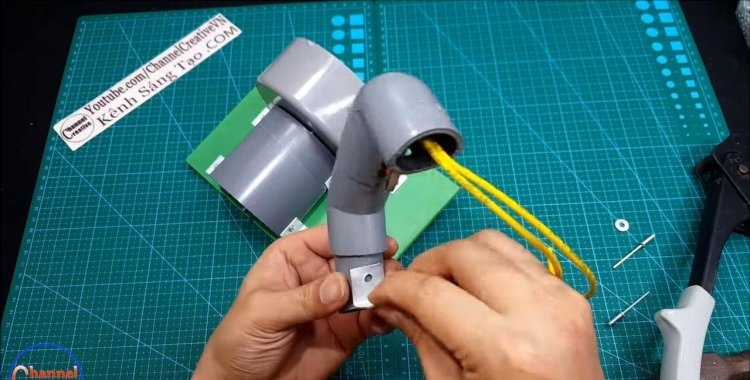

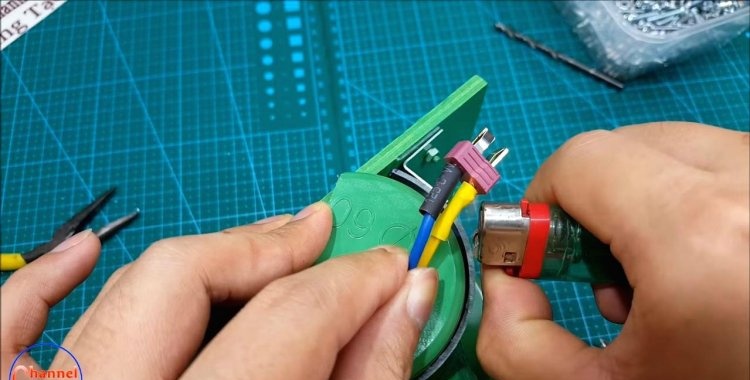

Switch and handle installation

Only after installing a switch (key type) into the handle can the handle itself be installed. When installing a circuit breaker, it is necessary to take into account the Amperage. The switch should be cut out and installed using hot glue.

The fixed handle is fixed at two points, after which the handle is fixed to the base. Epoxy glue is used to attach the second end to the motor casing. You should thoroughly clean the bonded surfaces with a Dremel or sandpaper, and then apply epoxy. Now your device is “not afraid” of any breakdown, because even if this happens, then by removing the handle along with the casing, you can fix everything.

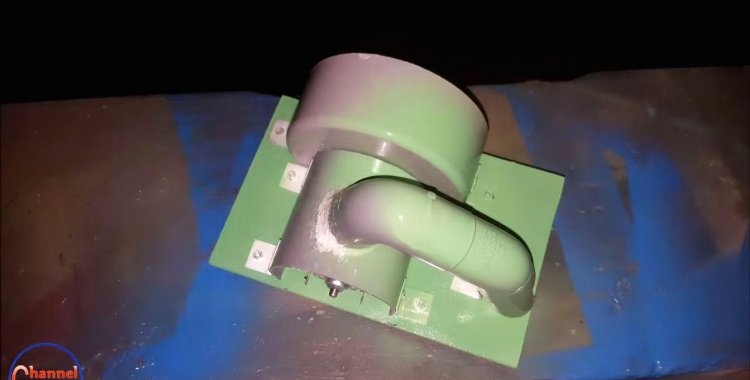

Applying paint

The product must be painted (for example, with a spray can), because this will give it additional respectability. In this case, you need to cover the switch and other non-paintable elements with tape.

Back cover

The back cover is made using a plug for plastic pipes of 60 mm diameter; you need to cut off all excess from it and try it on. Using a plug, also installed in this part, the device will be connected to a power source. It is necessary to cut a hole for the block.

Final assembly

Next, you can begin assembly; first of all, you need to output the power wires. We solder one wire directly to the motor contact, and the other into the gap through the switch. The ends of the wires should be brought out through the back cover and heat shrink should be applied. Next you need to solder the connector and then secure it to the cover.

After this, we secure the back cover and use a Dremel or sandpaper to grind down the screw caps on the working surface.

The car is ready, it's time for testing!

Saw tests

Correctly determining the polarity can be called the most important step in the process of connecting the saw to the power source. The success of this moment determines whether the saw will rotate in the direction required.

Verification is carried out experimentally!

To be able to take the saw with you to any place (for example, into the forest), 12 V batteries are used. For prolonged use in the workshop, it would be more appropriate to connect the saw via a power supply, but we must not forget that the current must be direct! Happy inventions to you!