Basically, bluing is used as a decorative coating, but initially, first of all, it is intended to protect the steel from corrosion.

I'll show you a way to make a simple knife bluing at home, using readily available components.

What do you need?

- - Boiling water 0.5 liters;

- - Citric acid 50 grams (can be bought at any grocery store).

The proportions are approximate, so it is not necessary to strictly follow them. It all depends on the volume of the container in which you will etch your blade. You need to know that increasing the concentration of citric acid accelerates the oxidation process, but at very high concentrations it can lead to uneven coating.

Knife bluing process

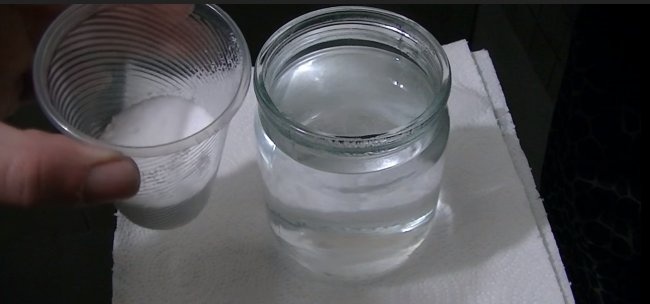

We take glassware the size of the knife blade so that it can be completely immersed in the solution.

Boil water in a kettle. Then we take and carefully pour boiling water into the jar. You have to be careful here, as the can may burst.To prevent this from happening, you can first pour a little boiling water on the bottom and let the jar warm up, then add the rest of the amount.

Next, add citric acid to the water and stir thoroughly until completely dissolved.

Before immersing the blade in the solution, it is advisable to wipe it with alcohol to remove all excess grease and dirt.

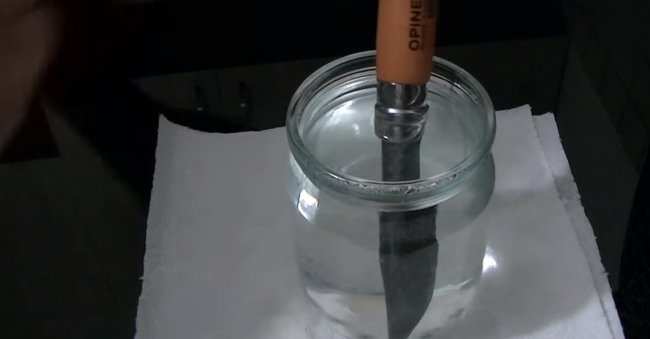

We plunge the knife blade.

After 1-2 minutes, a reaction will begin, which will be noticeable by numerous bubbles.

Burnishing will take you approximately 30 to 60 minutes. Everything again depends on your requirements for the color of the coating and the grade of steel of the knife.

During the entire bluing process, you must do the following:

- - Every 10 minutes, take out the knife and wipe the blade with a soft paper or cloth napkin, removing black deposits from the surface.

- - Approximately every 1-2 minutes it is necessary to move the blade in the solution, thereby discarding large gas bubbles from the blade. This will ensure even coverage.

After the time has passed, if you are satisfied with the color of the coating, you need to wipe the blade with sunflower oil one last time. This will stop the reaction and make the coating uniform and strong.

This completes the bluing of the knife blade.

At the end I want to add:

- Do not inhale pore gases when bluing, as they are harmful. And it’s better to use ventilation if you have it, or at least open a window in the room.

- For a stable process, the water must be hot. Blueing does not take place in cold water. Boiling water is not necessary, but it should be 80 degrees Celsius.

If you get small stains, don’t worry, they will go away after the first or second use.

This coating is quite durable and will last for many years.