In order to mount a plastic ceiling, it is necessary to prepare the following tools and materials:

- - wooden beam 30x30 mm. or a special metal profile for the installation of plastic panels - footage depending on the perimeter of the ceiling + lintels;

- - plastic panels - clearly measure the area of the hemmed ceiling;

- - starting strip (preferably in the color of plastic panels) - around the perimeter of the ceiling;

- - screws for wood or metal (depending on the material of the lintels);

- - hammer drill with a drill for 6, plastic wads;

- - laser level;

- - screwdriver;

- - a construction stapler with staples or self-tapping seeds (depending on the material of the lintels);

- - a marker or a simple pencil;

- - wiring and room lighting elements (chandelier or spotlights).

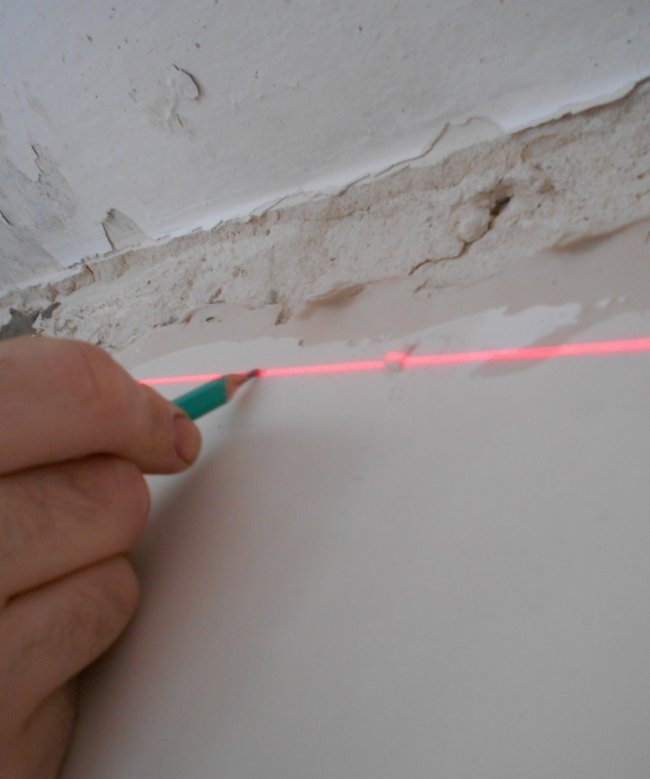

When all of the above is prepared, you can mount the plastic ceiling. The laser level around the perimeter of the room needs to beat off the lower boundary of the future ceiling.

With a simple pencil or marker, redraw the lines on the walls strictly according to the level.

Then attach a bar or profile to the wall.

To do this, drill holes in the wall with a puncher, insert plastic wads and attach a beam or profile strictly along the line. Then install parallel jumpers. The number of jumpers depends on the size of the ceiling.

They are installed no more than 1 meter apart. Then it is necessary to fasten along the wall with brackets or self-tapping screws a seed starting strip to the timber or profile. The corners of the starting strip, it is desirable to kill at an angle of 45 degrees. So they will look more aesthetically pleasing and beautiful. The next step is to lay the wiring for future lighting.

If it is one chandelier - bring the wiring to the center of the ceiling. And if there is spotlight, calculate the number of flashlights and display the wiring symmetrically to their location. After that, you can begin installing plastic panels on the ceiling. Cut the strip of plastic to the desired size and insert into the starting strip.

Fix the edge of the plastic to the jumper with brackets or self-tapping seeds. Then cut off the next strip of plastic panel, insert it already into the lock of the installed strip, press it well so that it clicks into place. Thus, it is necessary to fasten the plastic panels one by one. In the course of work, in places where the lighting will be installed, immediately make holes and mount lighting elements (spotlights or chandelier).

And also to install the remaining plastic panels to the last. And to insert the last plastic strip you will need a wide spatula. Use it to lower down the edge of the starting strip and insert the plastic into place. The main thing is not to overdo it so that the starting line does not burst. After all the work done, the plastic ceiling is considered mounted and it is ready for use.