Content

1. Characteristics of a bar stool.

2. Tools and materials.

3. Manufacturing sequence.

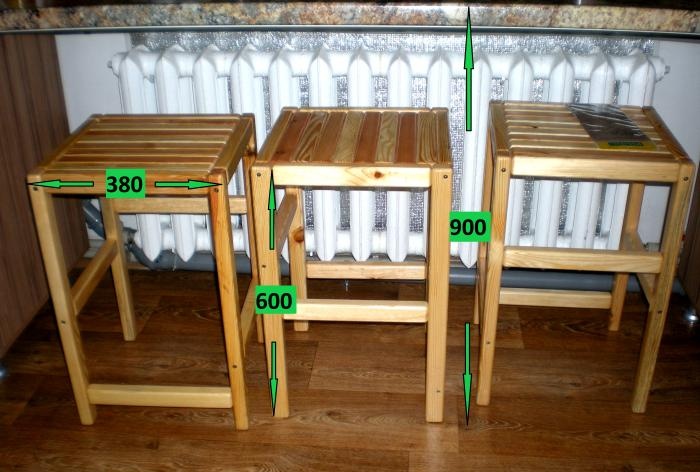

Bar stools are a convenient accessory for tables with a height of more than 850 mm. Outwardly, they may look similar to ordinary stools, but only with elongated legs. The height of the chair should be 300 - 350 mm lower than the level of the tabletop.

The remaining parameters (width, length, height of the legs, presence of a backrest) are adapted to the user’s wishes and the design of the room. Let's look at how you can make a bar stool with your own hands from timber, which, for example, can be purchased at hardware stores.

Tools and materials.

To make the presented model you will need the following set of tools:

- - square;

- - roulette;

- - a simple pencil;

- - drill;

- - drills with a diameter of 2.5 mm, 3.5 mm;

- - manual milling machine with attachments;

- - hammer;

- - a screwdriver with a Phillips profile;

- - sanding paper with different grain sizes;

- - vibrating grinding machine;

- - core;

- - soft brush for painting;

- - stationery knife.

The following materials are required, with the part number in parentheses:

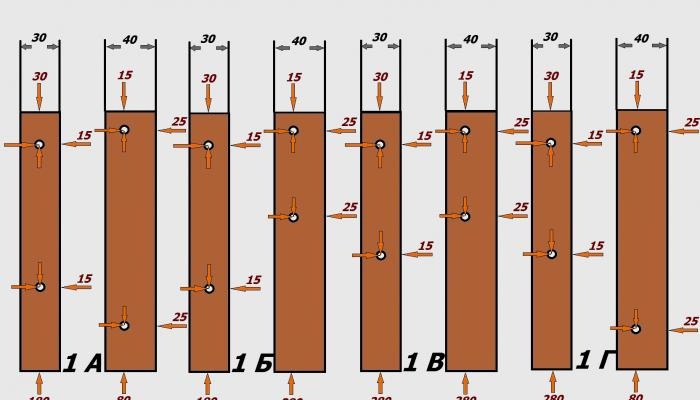

1. Wooden beam for legs, section 30 by 40 mm and length 600 mm, 4 pcs. (1A, 1B, 1C, 1D).

2.Wooden beams for drawers and legs with a section of 30 by 40 mm and a length of 300 mm – 4 pcs. (2); 320 mm – 4 pcs. (3).

3. Beam for connecting seat elements, size 25 x 30 x 315 mm – 2 pcs. (4).

4. Wooden beam for the seat with dimensions 20 x 40 x 320 mm – 8 pcs. (5).

5. PVA glue.

6. Screws, 80 mm long, 16 pcs. and 45 mm – 4 pcs.

7. Nails 1 x 30 mm – 16 pcs.

8. A rag for wiping off excess glue.

9. Clear varnish.

10. Felt coasters with a self-adhesive surface.

To prevent weakening of the chair structure, it is advisable to use all wooden elements without knots.

In the presented material, the bar stool is assembled from a common type of wood - pine.

Manufacturing sequence.

To make a bar stool with your own hands, you can follow the following sequence:

Step 1

Round the bars intended for legs, drawers, and legs on all sides using a manual milling machine and an appropriate attachment.

Step 2

Using a hand router with the same attachment as in step 1, round the seat blanks on one side to a length and width of 40mm.

Step 3.

Sand all elements of the chair with sandpaper until the surface is smooth.

Step 4

On the legs, drill holes with a diameter of 3.5 mm for fastening the legs and drawers. Their coordinates are shown in Figure 1.

Step 5

Based on the photo, lean the parts against each other and mark the mounting location with self-tapping screws through the holes in the legs.

To reduce the stress that occurs during the process of tightening fasteners at the ends of the parts, drill a blind hole with a diameter of 2.5 mm and a depth of about 30 mm.

Step 6

Using self-tapping screws along the drilled holes, fasten the blanks of legs, drawers, and legs together.

Step 7

On the resulting chair frame, unscrew the screws so that they do not come out of the body of the workpiece, but the ends of the part can be coated with glue.

Step 8

Lubricate the ends of the frame with glue and tighten the fastener until its head is flush with the surface of the beam. Use a rag to remove any protruding PVA particles.

Step 8

To frames No. 2, with 40 mm screws, attach a beam for fastening the seat on the inner side so that one side of the beam, 25 mm wide, is adjacent to the frame, and at the bottom is flush with it.

Step 9

Unscrew the screws from the workpiece for fastening the seat and apply glue to the side adjacent to the chair. Connect these elements.

Step 10

From the seat side, apply glue to the support beam (20 X 25 mm) and, placing the seat blanks closely, from the first to the eighth, nail them to the support. Drive the nail heads into the body of the wood with a core. Remove excess glue with a rag.

Step 11

Clean the surface of the chair from dust. Fill potholes and cavities in the wood. Sand all elements with sandpaper. Using a brush, apply the varnish evenly over the entire surface of the bar stool. Let the product dry.

Step 12

When using a solid fabric with self-adhesive film as a soft sole under the legs of a chair, determine the dimensions of the end part of the leg and, based on this data, cut out the corresponding elements from the specified material.

If standard soles are used for these purposes, then stick on self-adhesive felt and use a knife to cut it along the contour of the leg.

As you can see, it is very easy to make a bar stool with your own hands.