An asynchronous motor is used to rotate the pump turbine. To launch the anchor, you must create a phase shift at the initial stage of launch. This action is achieved using a capacitor located on the auxiliary winding.

Operating principle.

The capacitor consists of two metal plates placed in parallel, relative to each other, and interconnected by a dielectric gasket. The larger the plate area, the greater its capacity, which is measured in microfarads, picofarads, etc. When a positive voltage is applied to the capacitor contacts, this energy is accumulated between the plates, and when a negative voltage appears, it is transferred to the circuit. Since the alternating voltage consists of constantly changing negative and positive charges, due to the capacitor, the oscillations are aligned to the side of the positive voltage. This helps to create, at the initial stage of the operation of the induction motor, a magnetic field that rotates the armature.

Symptoms

In the event of a breakdown or loss of the capacitance of the capacitor by more than ± 15% of its nominal value, in the first version the circulation pump will not start, in the second case the motor will rotate jerkily.

Capacitor check.

There are several ways to test capacitors. Safe way - a special device for checking capacitors or an ohmmeter is used for verification, and a dangerous method is that conclusions about its performance are made by discharging a charged capacitor. Also, a broken capacitor has external characteristic symptoms of a malfunction: an electrolyte leak, a swollen body. It is not difficult to measure the capacitance of a capacitor with a special device. To do this, you just need to turn it on and set the lever to a greater than the checked face value, touch the probes to the contacts. Then compare the obtained value with the specified information on the case.

If the deviations are small (± 15%), the part is serviceable, if the values are missing or below the permissible range, then the starting capacitor should be replaced. We will not consider a dangerous method, since it violates safety precautions when working with capacitors.

Let us dwell on the indirect method of determining the state of the storage device using an ohmmeter.

The study of the performance of the capacitor with an ohmmeter.

To test the performance of the starting capacitor:

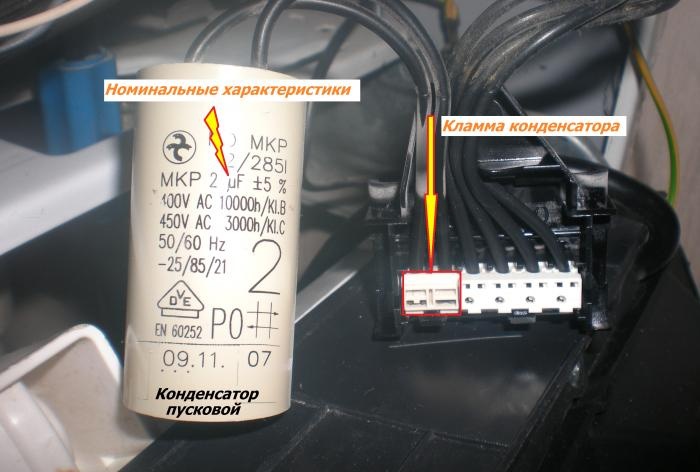

1. Disconnect its contacts from the engine.

2. For ease of measurement in some circulation pumps, the outer cover and terminals should be disconnected.

3. Before checking, discharge the capacitor, for this, close its contacts, for example, with a screwdriver with a flat profile.

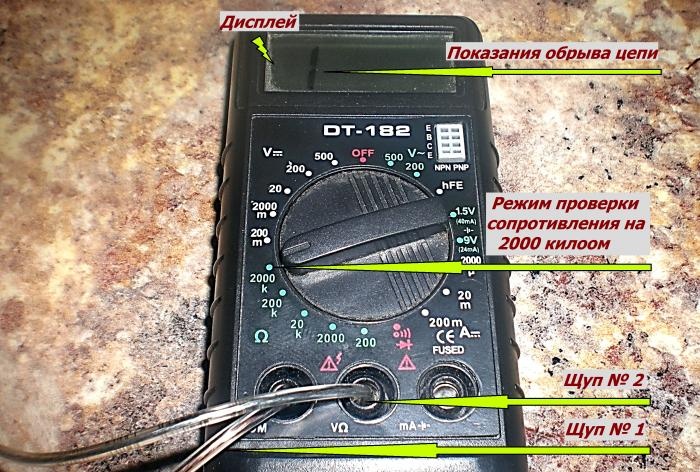

4. Switch the multimeter to 2000 kilo-ohm resistance test position.

5. Inspect the findings for mechanical damage, oxidation. Poor connection will adversely affect measurement accuracy.

6. Connect the feeler gauge to the capacitor leads and follow the numbers.If the values begin to change in this way: 1 ... 10 ... 102 ... 159 ... 1, then the capacitor is working. The numbers can be different, the main thing is that changes from 1 to 1. If the values of the device do not change (the number 1 lights up on the displays) or zero is displayed, then the part is faulty. To re-check, the capacitor should be discharged and repeat step No. 5 again.

The provided method will not allow to fully measure the capacitance of the capacitor, but will reveal its condition without a special device.