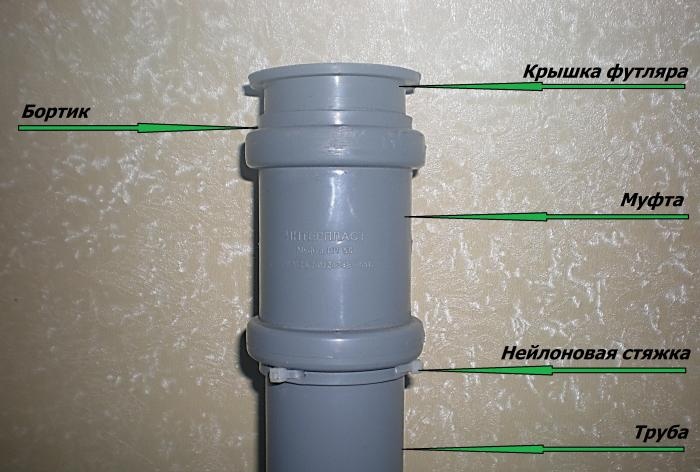

Case for the drill.

To make it, you will need the following tools and materials:

- roulette;

- pliers;

- an awl, with a diameter of 4 mm;

- marker or pencil;

- sewer pipe, with a diameter of 50 mm and a length of 1 meter;

- connecting sewer coupling, with a diameter of 50 mm, in the amount of 1 pc .;

- a cap for a sewer plastic system, with a diameter of 50 mm, in an amount of 2 pcs .;

- nylon screed, with a width of 3 mm and a length of 50 mm - 4 pcs.;

- screws, 3 mm thick and 20 mm long - 4 pcs.

Build Order:

1. On the flat end of the sewer pipe, through a standard rubber seal, put the sleeve in the middle of its length.

2.On the side of the coupling at the junction of it with the pipe, put 8 marks under the holes:

- 4 marks must be equidistant from each other along the circumference;

- next to these points, at a distance of 10 mm, mark another 1 hole.

3. With an awl, in the designated places, make holes with a diameter of 3 mm.

4. Using couplers, connect the coupling and the pipe. Tighten them with pliers as much as possible and bite off the protruding ends.

5. Insert a plug into the pipe with the adapter element and fix it with screws.

6. At the free end of the locked sleeve, install the rubber seal and strip its inner diameter with sandpaper until the cover is conveniently fixed in the case.

A tube for storing long objects, with a diameter of up to 50 mm and a length of up to 1 m, is ready. In this way, tubes of different sizes and designs are made from an extensive list of sewer systems.

Case for a gas burner.

The list of necessary tools and materials:

- a soldering iron for connecting plastic plumbing systems;

- scissors for cutting pipes or a hacksaw for metal;

- pencil and tape measure;

- awl;

- a plastic pipe with a diameter of 20 mm and a length of 0.2 m;

- a cap for a plastic water pipe, with a diameter of 20 mm, in an amount of 2 pcs.

Build Order:

1. Solder the plug to one end of the pipe. In the absence of a soldering iron, these parts can be connected with a gas torch. To do this, warm up the inner surface of the plug and about 10 seconds the outer part of the pipe at the junction for 15 seconds and quickly put the plug on the pipe until it stops.

2. Melt the inside of the other plug and warp it to fit comfortably on the other end of the pipe.

3. Make holes in the plug cover to reduce the concentration of gas in case it leaks from the burner.

Such a case reliably protects the contents from damage.