Well, what is the CBO, I think some have already guessed - this is a water cooling system. What water pump ? - This is a pump that makes coolant circulate through the system. In the article I will tell you one example of a homemade pump.

The engine of our homemade pump is a cooler. I took the standard 60 mm. and for a current of 300 mA I advise you to take a 120mm cooler with a maximum current for a normal result!

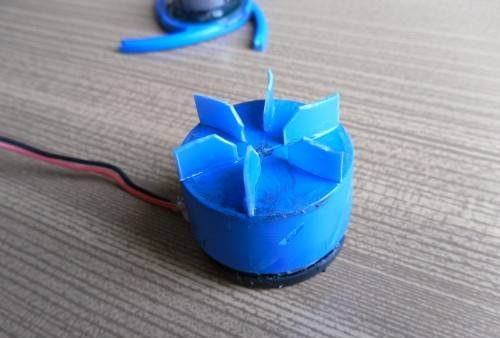

Let's get started. First, break off his outer casing and wings. See picture. Then we will draw it into 6 parts in order to then glue its impeller.

Coat with sealant or epoxy everything where water or coolant can get, because our cooler will be completely immersed in the liquid.

From a blue cap from the handle I cut an impeller. And stuck it.

Next, you need to take a vessel along the diameter of our engine and attach it there with glue. See the photo.

The output of the wires is coated with sealant. We do everything without gaps.

Glue on top a transparent cover with a hole in the center - this will be the entrance of water. The tube on its side is the exit.