Connection methods:

- twisting;

-through the terminal;

-through the clamp;

-bolt connection;

-soldering;

-through the tips.

Connecting wires using the twisting method.

This is the fastest and easiest way to connect one or more wires, so it is used most often than others. If the wires are twisted correctly, then when used in a home network with a light load, they will last a long time without being reminded of themselves.

Frequent mistakes when connecting wires using the twisting method.

The most common mistake that installers make is twisting wires of different metals (copper and aluminum).With such a connection, a complex process of electrolysis occurs in the twist, which leads to the destruction of the metal itself. It becomes covered with oxides and potholes. All this leads to poor contact at the junction, and subsequently heating. In the end, the conductors simply get burned by each other. This is accompanied by the smell of burning insulation, cracking, and sometimes fire.

How to twist wires with different metals correctly.

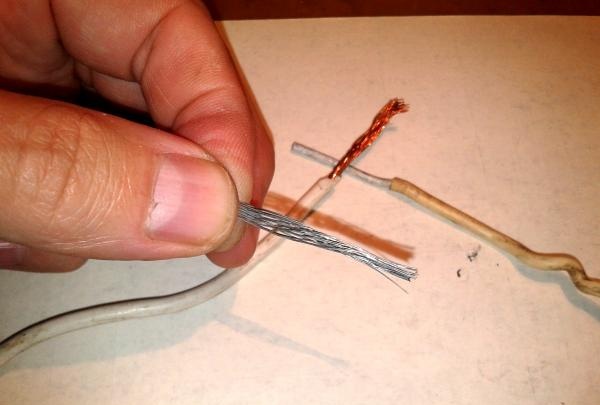

Find a small piece of tinned wire

and remove the insulation from it. Next, fluff up the wires and evenly wind them onto the aluminum wire. Using pliers, tightly wrap the copper conductor around it.

At the end, fold the excess onto this twist.

The copper is now in direct contact with the aluminum through the tinned wire. And this will prevent electrolysis from occurring on different conductors.

Connection via terminal.

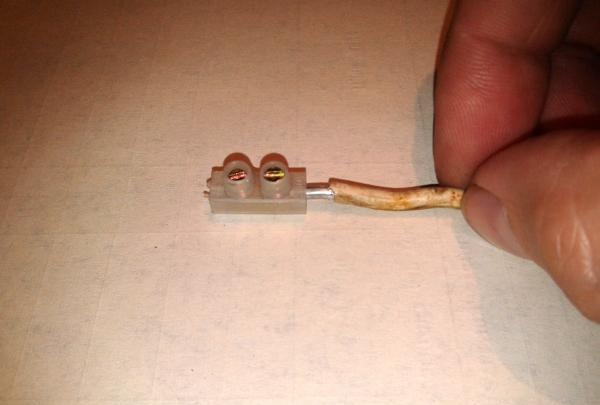

The presence of terminals can also make this work easier and ensure a quality connection. There are many types of terminals, but they have the same principle. The photo shows two types of terminals, which can often be seen in different devices.

For example, in fluorescent lamps, at the junction of the power wires. Also, these terminals are freely available for sale and can be supplied in quantities of 10 pieces. and more in length. Having purchased such a block, you can simply cut off the required number of elements with a knife. Connecting conductors of different metals in a terminal is not difficult. First you need to remove the insulation from the end of the wires by 3-4 mm so that the exposed area does not extend far beyond the terminal.

We unscrew the screws until the wire strands pass freely, and after inserting, we clamp them.

Do not apply too much force, otherwise the fragile threads will “break”, which will require replacing the terminal.This connection is quite reliable. With a current of up to 1.5 kW, it can easily cope with its task. It all depends on which terminal to use. Here we consider the weakest one; using a more powerful one, the flow current can be increased. In addition to the option of connecting wires made of different materials, terminals can be successfully used to increase the length. This can be useful in cases where the wire in the box is so short that it is not long enough to make a twist. This is where the terminal will help. The same applies to a broken wire coming from the ceiling to the lamp. By the way, this is a very common problem. Even if a little of the conductor still sticks out from the ceiling slab, the terminal will successfully help to extend it.

Connection via clamp. Sometimes you may have a clamp like this or a similar one at hand.

Then the problem with the connection can be solved with its help. How to do this is clear from the photograph.

After the screws are securely clamped, this entire exposed area must be insulated with adhesive PVC tape.

Bolted connection.

Bolts, nuts and washers are always at hand. Therefore, in the absence of clamps and terminals, they will also work. By the way, large-sized bolts are used to make fairly high-quality connections for powerful large-section cables, and this method is still successfully used in industrial enterprises.

So, you will need:

-bolt of the required length;

-screw;

-three wide washers.

First, we put one washer on the bolt, then we can use round-nose pliers to make rings or simply wrap the conductor around the thread with pliers.

You need to bend according to the movement of the thread. That is, so that when the nut is tightened, the loop does not open to the sides.

A washer between the two conductors will prevent them from touching and will prevent the electrolysis effect that destroys metals.

Soldering.

A soldered connection is considered to be of the highest quality, since the resistance in this place becomes minimal. Some people solder the twists in the boxes themselves, thus improving the connection. But it can be done with copper. And aluminum doesn't solder very well. Yes, you can use various acids and additives, but they, as a rule, destroy the compound themselves over time.

But with the help of rosin and tin you can tin a copper conductor. And after that, calmly twist it with aluminum. The connection will also be quite high quality.

Tips.

If you find such tips, it will be very good. This is one of the most reliable types of connection. We insert the wires into the lugs and clamp them with pliers, and then press them with a hammer and a clamp.

The lugs must be tinned, or you need to wrap the aluminum conductor with tinned wire before inserting it into the hole in the lug. Afterwards, the tips should be compressed with a bolt and nut, and everything should be insulated with tape.

Conclusion.

Of course, now there are more advanced methods and devices for connecting wires, but they need to be purchased and mastered, which takes extra money and time. The good old methods described above will be used for a long time, and will also serve faithfully for a long time. So why pay more?!