To facilitate the task of moving furniture and other devices, I propose a small upgrade. We mount the wheels on two supports. Why two, not all? For stability when used. Leaning, sitting on furniture with four wheels, we will move it, on two - it will remain in place, and it will be much more convenient to move it. In addition to convenience, the “skating” of furniture keeps carpets and floors from abrasion. The table, especially the sliding one, from destruction: by taking on the lid, and not on the table frame, the lid can be torn off with a sharp rise. It was these considerations that prompted the modernization of the table.

We will write down the main points in stages.

1. First we have a table.

You need to pick up a pair of identical wheels, they are best suited from a chair, they are easy to buy at a flea market or a specialized store.

2. Turn the table over. We measure the height of the wheel to the mounting shelf.

Cut off the legs of the table on one side to the measured height, + 3mm.

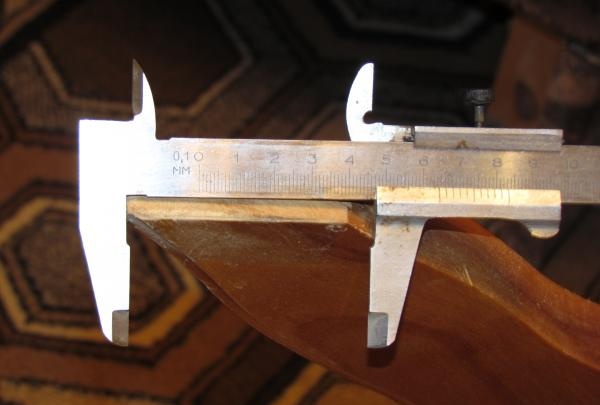

3. Measure the width and length of the support in the place of the cut.

4. We make a mounting bracket from 2-3 mm steel that completely covers the leg, sufficient for mounting the wheel.

In it, we drill holes for attaching to the leg, a diameter of not more than 4 mm, and a landing hole for the wheel.

5. The table leg is a solid enough wood. However, you should not risk it and chop the tree when tightening the screws. Attach the bracket with the fixed wheel to the seat, mark the centers of the mounting holes. Measure a sufficient length, cut the screws as necessary.

Drill a hole with a diameter of 3/4 screw to mark the length of the screw.

6. We process the cut points with a file, remove the burrs on the tree, round the edges for a more snug fit of the bracket.

7. Once again, we check the tightness of the fit of the bracket assembly, if everything is fine, we proceed to the processing of the cut site with any varnish or paint. Attention! Do not allow varnish or paint to drip below the cut surface.

8. Finally fix the wheel with a nut, counter-clamp for reliability.

9. We fasten all the brackets to the prepared legs, carry out “sea trials”.

When operating modernized furniture, a significant drawback will be revealed - the risk of injury to the metal bracket, its sharp corners. The problem can be solved by giving rounded shapes to the protruding parts. It is easy to make a grinder, if not, work with a file. The problem is not completely solved, the protruding part of the metal remains dangerous. It is better to put a plastic profile on a rectangular bracket, cutting it out of a children's toy, bend it on a blank of sheet plastic with an industrial hair dryer.